/*

Name: FourWD_WallTrackTest.ino

Created: 6/18/2021 7:20:58 PM

Author: FRANKNEWXPS15\Frank

*/

/*

Name: FourWD_PulseTurnRateTest.ino

Created: 5/24/2021 4:49:52 PM

Author: FRANKNEWXPS15\Frank

*/

#pragma region INCLUDES

#include <PID_v2.h>

#include <elapsedMillis.h>

#include <PrintEx.h> //allows printf-style printout syntax

#include "MPU6050_6Axis_MotionApps_V6_12.h" //changed to this version 10/05/19

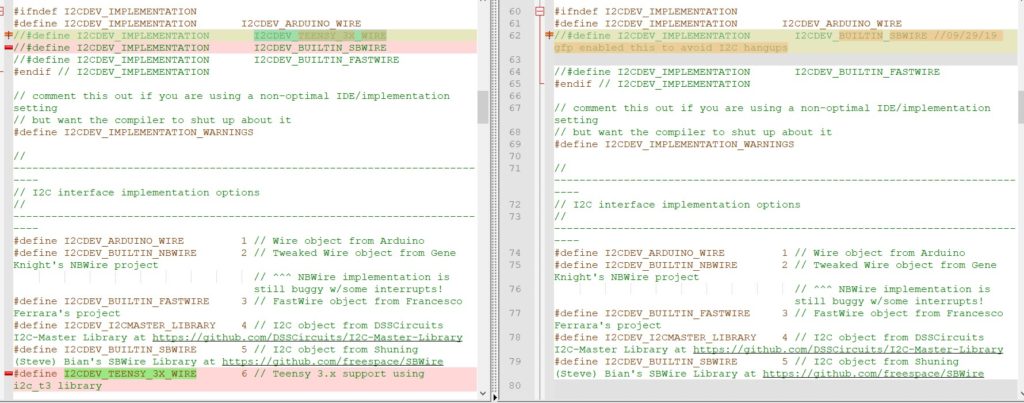

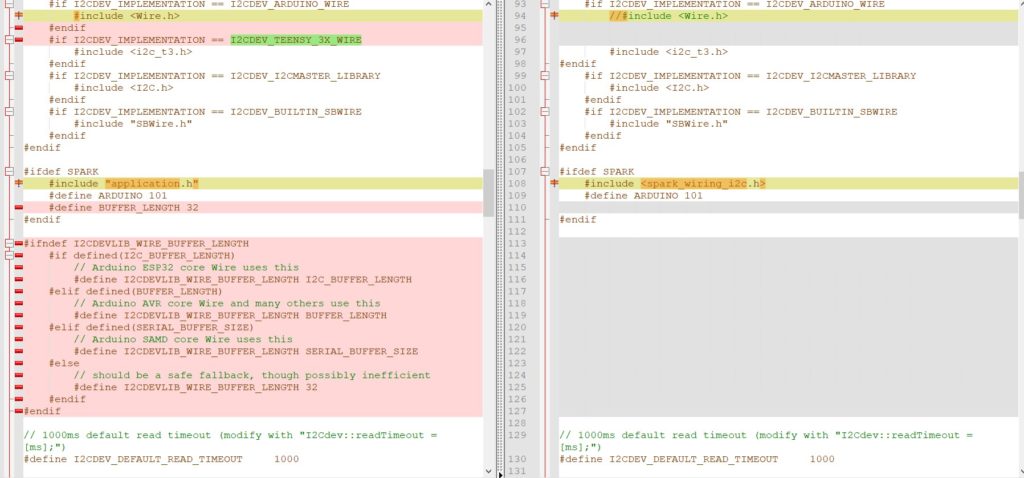

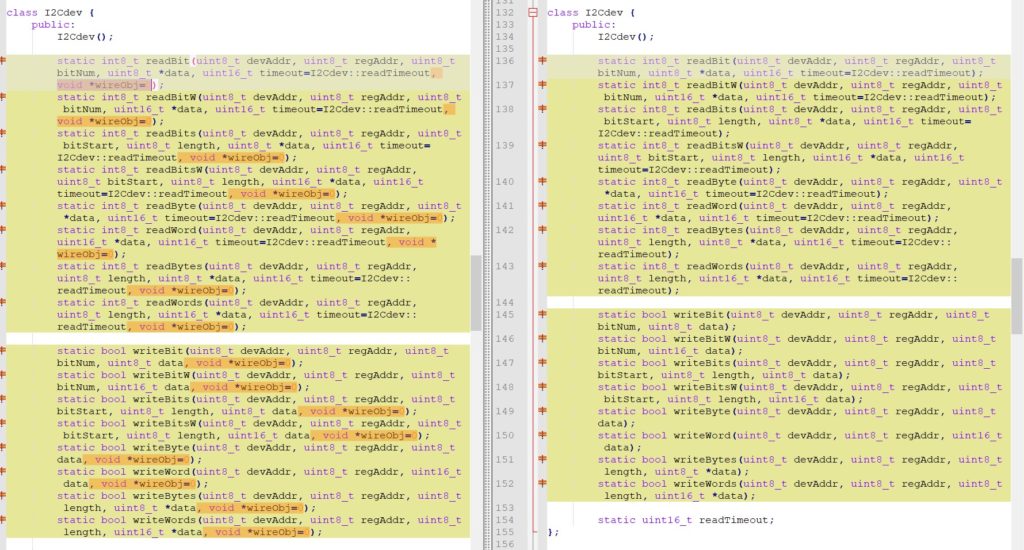

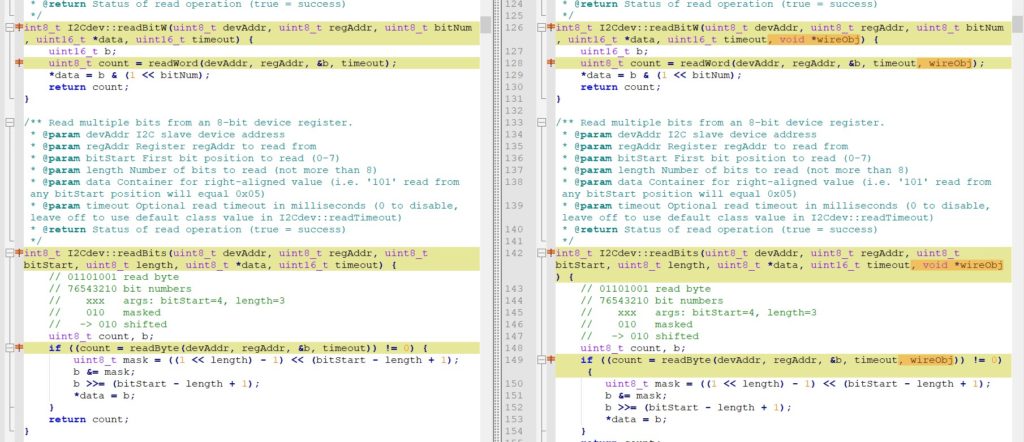

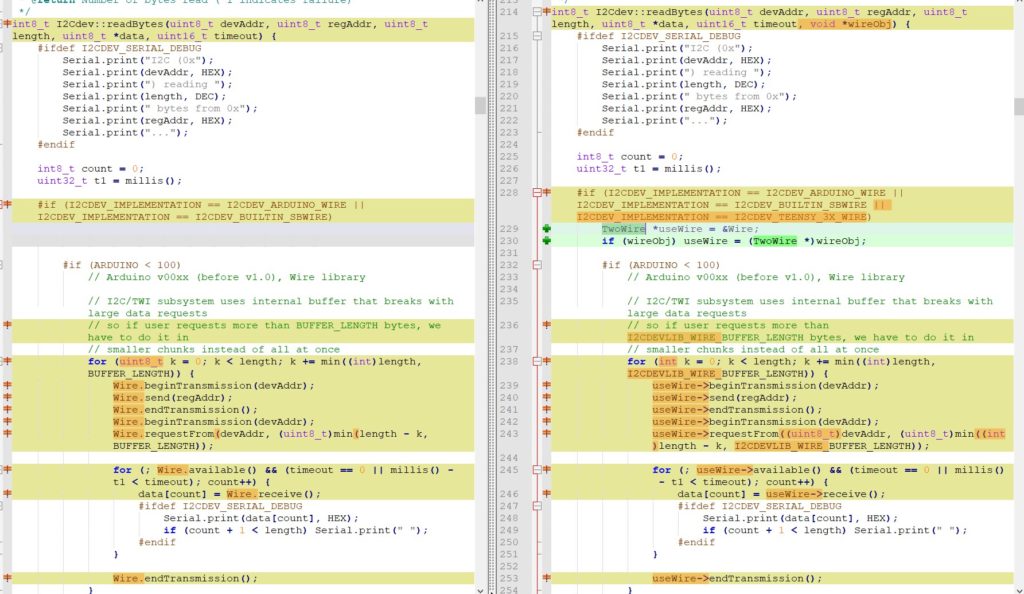

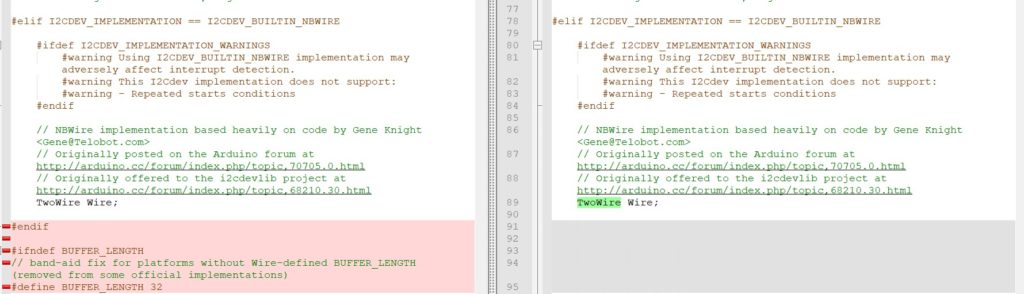

#include "I2Cdev.h" //02/19/19: this includes SBWire.h

#include "I2C_Anything.h" //needed for sending float data over I2C

#pragma endregion INCLUDES

#pragma region DEFINES

#define MPU6050_I2C_ADDR 0x69

//#define DISTANCES_ONLY //added 11/14/18 to just display distances in infinite loop

#pragma endregion DEFINES

#pragma region PRE_SETUP

StreamEx mySerial = Serial; //added 03/18/18 for printf-style printing

MPU6050 mpu(MPU6050_I2C_ADDR); //06/23/18 chg to AD0 high addr, using INT connected to Mega pin 2 (INT0)

volatile int frontdistval = 0; //10/10/20 chg to volatile

volatile double frontvar = 0; //08/11/20 now updated in timer1 ISR

const int MAX_FRONT_DISTANCE_CM = 400;

const int FRONT_DIST_AVG_WINDOW_SIZE = 3; //moved here & renamed 04/28/19

const int FRONT_DIST_ARRAY_SIZE = 50; //11/22/20 doubled to acct for 10Hz update rate

uint16_t aFrontDist[FRONT_DIST_ARRAY_SIZE]; //04/18/19 rev to use uint16_t vs byte

//11/03/18 added for new incremental variance calc

double Front_Dist_PrevVar = 0;

double Front_Dist_PrevVMean = 0;

#pragma endregion PRE_SETUP

#pragma region MOTOR_PINS

//09/11/20 Now using two Adafruit DRV8871 drivers for all 4 motors

const int In1_Left = 10;

const int In2_Left = 11;

const int In1_Right = 8;

const int In2_Right = 9;

#pragma endregion Motor Pin Assignments

#pragma region MISC_PIN_ASSIGNMENTS

const int RED_LASER_DIODE_PIN = 7;

const int LIDAR_MODE_PIN = 4; //mvd here 01/10/18

#pragma endregion MISC_PIN_ASSIGNMENTS

#pragma region MOTOR_PARAMETERS

//drive wheel speed parameters

const int MOTOR_SPEED_FULL = 200; //range is 0-255

const int MOTOR_SPEED_MAX = 255; //range is 0-255

const int MOTOR_SPEED_HALF = 127; //range is 0-255

const int MOTOR_SPEED_QTR = 75; //added 09/25/20

const int MOTOR_SPEED_LOW = 50; //added 01/22/15

const int MOTOR_SPEED_OFF = 0; //range is 0-255

//drive wheel direction constants

const boolean FWD_DIR = true;

const boolean REV_DIR = !FWD_DIR;

const bool TURNDIR_CCW = true;

const bool TURNDIR_CW = false;

//Motor direction variables

boolean bLeftMotorDirIsFwd = true;

boolean bRightMotorDirIsFwd = true;

bool bIsForwardDir = true; //default is foward direction

#pragma endregion Motor Parameters

#pragma region HEADING_AND_RATE_BASED_TURN_PARAMETERS

elapsedMillis MsecSinceLastTurnRateUpdate;

const int MAX_PULSE_WIDTH_MSEC = 100;

const int MIN_PULSE_WIDTH_MSEC = 0;

const int MAX_SPIN_MOTOR_SPEED = 250;

const int MIN_SPIN_MOTOR_SPEED = 50;

const int TURN_RATE_UPDATE_INTERVAL_MSEC = 30;

double Prev_HdgDeg = 0;

float tgt_deg;

float timeout_sec;

//05/31/21 latest & greatest PID values

double TurnRate_Kp = 5.0;

double TurnRate_Ki = 1;

double TurnRate_Kd = 0.5;

double TurnRatePIDSetPointDPS, TurnRatePIDOutput;

double TurnRatePIDInput = 15.f;

PID TurnRatePID(&TurnRatePIDInput, &TurnRatePIDOutput, &TurnRatePIDSetPointDPS, TurnRate_Kp, TurnRate_Ki, TurnRate_Kd, DIRECT);

const float HDG_NEAR_MATCH_VAL = 0.8; //slow the turn down here

const float HDG_FULL_MATCH_VAL = 0.99; //stop the turn here //rev 05/17/20

const float HDG_MIN_MATCH_VAL = 0.6; //added 09/08/18: don't start checking slope until turn is well started

#pragma endregion HEADING_AND_RATE_BASED_TURN_PARAMETERS

const double RATIO_TURN_MATCH_THRESHOLD = 0.1;

#pragma region MPU6050_SUPPORT

uint8_t mpuIntStatus; // holds actual interrupt status byte from MPU. Used in Homer's Overflow routine

uint8_t devStatus; // return status after each device operation (0 = success, !0 = error)

uint16_t packetSize; // expected DMP packet size (default is 42 bytes)

uint16_t fifoCount; // count of all bytes currently in FIFO

uint8_t fifoBuffer[64]; // FIFO storage buffer

// orientation/motion vars

Quaternion q; // [w, x, y, z] quaternion container

VectorInt16 aa; // [x, y, z] accel sensor measurements

VectorInt16 aaReal; // [x, y, z] gravity-free accel sensor measurements

VectorInt16 aaWorld; // [x, y, z] world-frame accel sensor measurements

VectorFloat gravity; // [x, y, z] gravity vector

float euler[3]; // [psi, theta, phi] Euler angle container

float ypr[3]; // [yaw, pitch, roll] yaw/pitch/roll container and gravity vector

int GetPacketLoopCount = 0;

int OuterGetPacketLoopCount = 0;

//MPU6050 status flags

bool bMPU6050Ready = true;

bool dmpReady = false; // set true if DMP init was successful

volatile float IMUHdgValDeg = 0; //updated by UpdateIMUHdgValDeg()//11/02/20 now updated in ISR

const uint16_t MAX_GETPACKET_LOOPS = 100; //10/30/19 added for backup loop exit condition in GetCurrentFIFOPacket()

uint8_t GetCurrentFIFOPacket(uint8_t* data, uint8_t length, uint16_t max_loops = MAX_GETPACKET_LOOPS); //prototype here so can define a default param

bool bFirstTime = true;

#define MPU6050_CCW_INCREASES_YAWVAL //added 12/05/19

#pragma endregion MPU6050 Support

#pragma region WALL_FOLLOW_SUPPORT

const int WALL_OFFSET_TRACK_Kp = 100;

const int WALL_OFFSET_TRACK_Ki = 0;

const int WALL_OFFSET_TRACK_Kd = 0;

//const double WALL_OFFSET_TRACK_SETPOINT_LIMIT = 0.3;

//const double WALL_OFFSET_TRACK_SETPOINT_LIMIT = 0.4;

//const double WALL_OFFSET_TRACK_SETPOINT_LIMIT = 0.5;

//const double WALL_OFFSET_TRACK_SETPOINT_LIMIT = 0.15;

const double WALL_OFFSET_TRACK_SETPOINT_LIMIT = 0.25;

double WallTrackSteerVal, WallTrackOutput, WallTrackSetPoint;

const int CHG_CONNECT_LED_PIN = 50; //12/16/20 added for debug

const int WALL_OFFSET_TGTDIST_CM = 30;

double LeftSteeringVal, RightSteeringVal; //added 08/06/20

const int WALL_TRACK_UPDATE_INTERVAL_MSEC = 50;

//const int WALL_TRACK_UPDATE_INTERVAL_MSEC = 30;

#pragma endregion WALL_FOLLOW_SUPPORT

#pragma region VL53L0X LIDAR SUPPORT

//VL53L0X Sensor data values

//11/05/20 revised to make all volatile

volatile int Lidar_RightFront;

volatile int Lidar_RightCenter;

volatile int Lidar_RightRear;

volatile int Lidar_LeftFront;

volatile int Lidar_LeftCenter;

volatile int Lidar_LeftRear;

volatile int Lidar_Rear; //added 10/24/20

bool bVL53L0X_TeensyReady = false; //11/10/20 added to prevent bad data reads during Teensy setup()

enum VL53L0X_REQUEST

{

VL53L0X_READYCHECK, //added 11/10/20 to prevent bad reads during Teensy setup()

VL53L0X_CENTERS_ONLY,

VL53L0X_RIGHT,

VL53L0X_LEFT,

VL53L0X_ALL, //added 08/06/20, replaced VL53L0X_BOTH 10/31/20

VL53L0X_REAR_ONLY //added 10/24/20

};

const int VL53L0X_I2C_SLAVE_ADDRESS = 0x20; ////Teensy 3.5 VL53L0X ToF LIDAR controller

#pragma endregion VL53L0X LIDAR SUPPORT

//************************************************************************************************************************************

//*********************************************************** TIMER ISR **************************************************************

//************************************************************************************************************************************

#pragma region TIMER_ISR

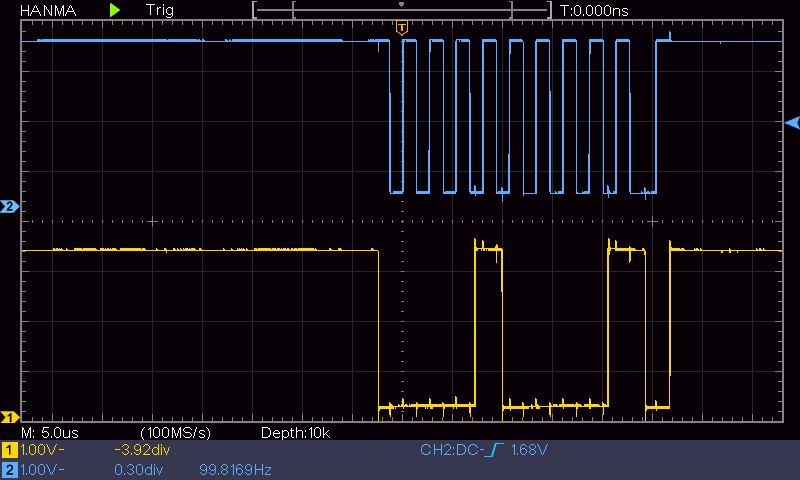

#define TIMER_INT_OUTPUT_PIN 53 //scope monitor pin

bool GetRequestedVL53l0xValues(VL53L0X_REQUEST which);

volatile bool bTimeForNavUpdate = false;

const int TIMER5_INTERVAL_MSEC = 100; //05/15/21 added to eliminate magic number

int GetFrontDistCm();

ISR(TIMER5_COMPA_vect) //timer5 interrupt 5Hz

{

digitalWrite(TIMER_INT_OUTPUT_PIN, HIGH);//so I can monitor interrupt timing

delayMicroseconds(30); //leave in - so can see even with NO_STUCK defined

bTimeForNavUpdate = true;

//11/2/20 have to re-enable interrupts for I2C comms to work

interrupts();

GetRequestedVL53l0xValues(VL53L0X_ALL); //11/2/20 update all distances every 100mSec

noInterrupts();

frontdistval = GetFrontDistCm();

digitalWrite(TIMER_INT_OUTPUT_PIN, LOW);//so I can monitor interrupt timing

}

#pragma endregion TIMER_ISR

void setup()

{

Serial.begin(115200);

#pragma region MPU6050

mySerial.printf("\nChecking for MPU6050 IMU at I2C Addr 0x%x\n", MPU6050_I2C_ADDR);

mpu.initialize();

// verify connection

Serial.println(mpu.testConnection() ? F("MPU6050 connection successful") : F("MPU6050 connection failed"));

float StartSec = 0; //used to time MPU6050 init

Serial.println(F("Initializing DMP..."));

devStatus = mpu.dmpInitialize();

// make sure it worked (returns 0 if successful)

if (devStatus == 0)

{

// turn on the DMP, now that it's ready

Serial.println(F("Enabling DMP..."));

mpu.setDMPEnabled(true);

// set our DMP Ready flag so the main loop() function knows it's okay to use it

Serial.println(F("DMP ready! Waiting for MPU6050 drift rate to settle..."));

dmpReady = true;

// get expected DMP packet size for later comparison

packetSize = mpu.dmpGetFIFOPacketSize();

bMPU6050Ready = true;

StartSec = millis() / 1000.f;

mySerial.printf("MPU6050 Ready at %2.2f Sec\n", StartSec);

}

else

{

// ERROR!

// 1 = initial memory load failed

// 2 = DMP configuration updates failed

// (if it's going to break, usually the code will be 1)

Serial.print(F("DMP Initialization failed (code "));

Serial.print(devStatus);

Serial.println(F(")"));

bMPU6050Ready = false;

}

#pragma endregion MPU6050

#pragma region PIN_INITIALIZATION

pinMode(LIDAR_MODE_PIN, INPUT); // Set LIDAR input monitor pin

#pragma endregion PIN_INITIALIZATION

#pragma region TIMER_INTERRUPT

//09/18/20 can't use Timer1 cuz doing so conflicts with PWM on pins 10-12

cli();//stop interrupts

TCCR5A = 0;// set entire TCCR5A register to 0

TCCR5B = 0;// same for TCCR5B

TCNT5 = 0;//initialize counter value to 0

// 06/15/21 rewritten to use defined interval constant rather than magic number

//10/11/20 chg timer interval to 10Hz vs 5

//OCR5A = 1562;// = (16*10^6) / (10*1024) - 1 (must be <65536)

int ocr5a = (16 * 1e6) / ((1000 / TIMER5_INTERVAL_MSEC) * 1024) - 1;

mySerial.printf("ocr5a = %d\n", ocr5a);

OCR5A = ocr5a;

TCCR5B |= (1 << WGM52);// turn on CTC mode

TCCR5B |= (1 << CS52) | (1 << CS50);// Set CS10 and CS12 bits for 1024 prescaler

TIMSK5 |= (1 << OCIE5A);// enable timer compare interrupt

sei();//allow interrupts

pinMode(TIMER_INT_OUTPUT_PIN, OUTPUT);

#pragma endregion TIMER_INTERRUPT

//02/08/21 mvd below ISR enable so this section can use ISR-generated VL53L0X distances

#pragma region VL53L0X_TEENSY

mySerial.printf("Checking for Teensy 3.5 VL53L0X Controller at I2C addr 0x%x\n", VL53L0X_I2C_SLAVE_ADDRESS);

while (!bVL53L0X_TeensyReady)

{

Wire.beginTransmission(VL53L0X_I2C_SLAVE_ADDRESS);

bVL53L0X_TeensyReady = (Wire.endTransmission() == 0);

//mySerial.printf("%lu: VL53L0X Teensy Not Avail...\n", millis());

delay(100);

}

mySerial.printf("Teensy available at %lu with bVL53L0X_TeensyReady = %d. Waiting for Teensy setup() to finish\n", millis(), bVL53L0X_TeensyReady);

WaitForVL53L0XTeensy();

//mySerial.printf("VL53L0X Teensy Ready at %lu\n\n", millis());

#pragma endregion VL53L0X_TEENSY

//11/14/18 added this section for distance printout only

//08/06/20 revised for VL53L0X support

#ifdef DISTANCES_ONLY

TIMSK5 = 0;

digitalWrite(RED_LASER_DIODE_PIN, HIGH); //enable the front laser dot

mySerial.printf("\n------------ DISTANCES ONLY MODE!!! -----------------\n\n");

int i = 0; //added 09/20/20 for in-line header display

mySerial.printf("Msec\tLFront\tLCenter\tLRear\tRFront\tRCenter\tRRear\tRear\n");

while (true)

{

//if (bTimeForNavUpdate)

//{

// bTimeForNavUpdate = false;

//09/20/20 re-display the column headers

//if (++i % 20 == 0)

//{

// mySerial.printf("\nMsec\tLFront\tLCenter\tLRear\tRFront\tRCenter\tRRear\tFront\tRear\n");

//}

//commented out 02/02/21 - now done in ISR

GetRequestedVL53l0xValues(VL53L0X_ALL);

mySerial.printf("%lu\t%d\t%d\t%d\t%d\t%d\t%d\t%d\t%d\n",

millis(), Lidar_LeftFront, Lidar_LeftCenter, Lidar_LeftRear,

Lidar_RightFront, Lidar_RightCenter, Lidar_RightRear, frontdistval, Lidar_Rear);

//}

delay(50);

}

TIMSK5 |= (1 << OCIE5A);// enable timer compare interrupt

#endif // DISTANCES_ONLY

#pragma region L/R/FRONT DISTANCE ARRAYS

//09/20/20 have to do this for parallel finding to go the right way

Serial.println(F("Initializing Left, Right, Front Distance Arrays..."));

#ifndef NO_PINGS

//03/30/21 moved FrontDistArray init ahead of left/right dist init to prevent inadvertent 'stuck' detection

Serial.println(F("Initializing Front Distance Array"));

InitFrontDistArray(); //08/12/20 code extracted to fcn so can call elsewhere

//Serial.println(F("Updating Left\tRight Distance Arrays"));

//for (size_t i = 0; i < LR_DIST_ARRAY_SIZE; i++)

//{

// delay(100); //ensure enough time for ISR to update distances

// mySerial.printf("%d\t%d\n", Lidar_LeftCenter, Lidar_RightCenter);

// UpdateLRDistanceArrays(Lidar_LeftCenter, Lidar_RightCenter);

//}

//Serial.println(F("Updating Rear Distance Arrays"));

//InitRearDistArray();

//mySerial.printf("Initial rear prev_mean, prev_var = %2.2f, %2.2f\n",

// Rear_Dist_PrevMean, Rear_Dist_PrevVar);

#else

Serial.println(F("Distance Sensors Disabled"));

#endif // NO_PINGS

#pragma endregion L/R/FRONT DISTANCE ARRAYS

#pragma region WALL_TRACK_TEST

mySerial.printf("End of test - Stopping!\n");

//while (true)

//{

// CheckForUserInput();

//}

StopBothMotors();

Serial.println(F("Setting Kp value"));

const int bufflen = 80;

char buff[bufflen];

memset(buff, 0, bufflen);

float OffsetCm;

float Kp, Ki, Kd;

const char s[2] = ",";

char* token;

//consume CR/LF chars

while (Serial.available() > 0)

{

int byte = Serial.read();

mySerial.printf("consumed %d\n", byte);

}

while (!Serial.available())

{

}

Serial.readBytes(buff, bufflen);

mySerial.printf("%s\n", buff);

/* extract Kp */

token = strtok(buff, s);

Kp = atof(token);

/* extract Ki */

token = strtok(NULL, s);

Ki = atof(token);

/* extract Kd */

token = strtok(NULL, s);

Kd = atof(token);

/* extract Offset in cm */

token = strtok(NULL, s);

OffsetCm = atof(token);

//mySerial.printf("Kp,Ki,Kd,OffsetCm = %2.2f, %2.2f, %2.2f, %2.2f\n",

// Kp, Ki, Kd, OffsetCm);

//TrackLeftWallOffset(Kp, Ki, Kd, OffsetCm);

TrackRightWallOffset(Kp, Ki, Kd, OffsetCm);

//mySerial.printf("Rdist\tCdist\tFdist\tsteer\toffang\n");

//while (true)

//{

// //double offangdeg = GetSteeringAngle(Lidar_LeftCenter / 10, LeftSteeringVal);

// double offangdeg = GetSteeringAngle(LeftSteeringVal); //06/25/21 chg to mm vs cm

// mySerial.printf("%d\t%d\t%d\t%2.4f\t%2.2f\n", Lidar_LeftRear, Lidar_LeftCenter, Lidar_LeftFront, LeftSteeringVal, offangdeg);

// delay(1000);

//}

#pragma endregion WALL_TRACK_TEST

}

void loop()

{

}

void CheckForUserInput()

{

const int bufflen = 80;

char buff[bufflen];

memset(buff, 0, bufflen);

float OffsetCm;

float Kp, Ki, Kd;

const char s[2] = ",";

char* token;

if (Serial.available() > 0)

{

// read the incoming byte:

int incomingByte = Serial.read();

// say what you got:

//Serial.print("I received: ");

//Serial.println(incomingByte, HEX); //chg to HEX 02/18/20

//02/18/20 experiment with multiple commands

switch (incomingByte)

{

case 0x43: //ASCII 'C'

case 0x63: //ASCII 'c'

#pragma region MANUALCONTROL

//enter infinite loop for direct remote control

Serial.println(F("ENTERING COMMAND MODE:"));

Serial.println(F("0 = 180 deg CCW Turn"));

Serial.println(F("1 = 180 deg CW Turn"));

Serial.println(F("A = Back to Auto Mode"));

Serial.println(F("S = Stop"));

Serial.println(F("F = Forward"));

Serial.println(F("R = Reverse"));

Serial.println(F(""));

Serial.println(F(" Faster"));

Serial.println(F("\t8"));

Serial.println(F("Left 4\t5 6 Right"));

Serial.println(F("\t2"));

Serial.println(F(" Slower"));

StopBothMotors();

int speed = 0;

bool bAutoMode = false;

while (!bAutoMode)

{

if (Serial.available() > 0)

{

// read the incoming byte:

int incomingByte = Serial.read();

//mySerial.printf("Got %x\n", incomingByte);

switch (incomingByte)

{

case 0x54: //ASCII 'T'

case 0x74: //ASCII 't'

Serial.println(F("Toggle TIMER5 Enable/Disable"));

if (TIMSK5 == 0)

{

Serial.println(F("Enable TIMER5"));

//TIMSK5 |= OCIE5A;

TIMSK5 |= (1 << OCIE5A);// enable timer compare interrupt

mySerial.printf("TIMSK5 = %x\n", TIMSK5);

}

else

{

Serial.println(F("Disable TIMER5"));

TIMSK5 = 0;

mySerial.printf("TIMSK5 = %x\n", TIMSK5);

}

break;

case 0x44: //ASCII 'D'

case 0x64: //ASCII 'd'

Serial.println(F("Display left/right distances"));

if (TIMSK5 == 0)

{

Serial.println(F("Enable TIMER5"));

//TIMSK5 |= OCIE5A;

TIMSK5 |= (1 << OCIE5A);// enable timer compare interrupt

mySerial.printf("TIMSK5 = %x\n", TIMSK5);

}

mySerial.printf("Msec\tLF\tLC\tLR\tRF\tRC\tRR\n");

while (true)

{

if (bTimeForNavUpdate)

{

bTimeForNavUpdate = false;

mySerial.printf("%lu\t%d\t%d\t%d\t%d\t%d\t%d\n", millis(),

Lidar_LeftFront, Lidar_LeftCenter, Lidar_LeftRear, Lidar_RightFront, Lidar_RightCenter, Lidar_RightRear);

}

}

break;

case 0x30: //Dec '0'

Serial.println(F("CCW 180 deg Turn"));

//RollingTurn(true, bIsForwardDir, 180);

//SpinTurn(true, 180, 45);

SpinTurn(true, 180, 90);

MoveAhead(speed, speed);

break;

case 0x31: //Dec '1'

Serial.println(F("CW 180 deg Turn"));

//RollingTurn(false, bIsForwardDir, 180);

SpinTurn(false, 180, 45);

//MoveAhead(speed, speed);

break;

case 0x34: //Turn left 10 deg

Serial.println(F("CCW 10 deg Turn"));

//MoveAhead(speed, speed);

//RollingTurn(true, bIsForwardDir, 10);

SpinTurn(true, 10, 30);

//SpinTurn(true, 30, 30);

//added 05/03/20

if (bIsForwardDir)

{

MoveAhead(speed, speed);

}

else

{

MoveReverse(speed, speed);

}

break;

case 0x36: //Turn right 10 deg'

mySerial.print("CW 10 deg Turn\n");

MoveAhead(speed, speed);

//RollingTurn(false, bIsForwardDir, 10);

SpinTurn(false, 10, 30);

//SpinTurn(false, 45, 30);

//added 05/03/20

if (bIsForwardDir)

{

MoveAhead(speed, speed);

}

else

{

MoveReverse(speed, speed);

}

break;

case 0x38: //Speed up

speed += 50;

speed = (speed >= MOTOR_SPEED_MAX) ? MOTOR_SPEED_MAX : speed;

mySerial.printf("Speeding up: speed now %d\n", speed);

if (bIsForwardDir)

{

MoveAhead(speed, speed);

}

else

{

MoveReverse(speed, speed);

}

break;

case 0x32: //Slow down

speed -= 50;

speed = (speed < 0) ? 0 : speed;

mySerial.printf("Slowing down: speed now %d\n", speed);

if (bIsForwardDir)

{

MoveAhead(speed, speed);

}

else

{

MoveReverse(speed, speed);

}

break;

case 0x35: //05/07/20 changed to use '5' vs 'S'

Serial.println(F("Stopping Motors!"));

StopBothMotors();

speed = 0;

break;

case 0x41: //ASCII 'A'

case 0x61: //ASCII 'a'

StopBothMotors();

Serial.println(F("Re-entering AUTO mode"));

bAutoMode = true;

break;

case 0x52: //ASCII 'R'

case 0x72: //ASCII 'r'

Serial.println(F("Setting both motors to reverse"));

bIsForwardDir = false;

MoveReverse(speed, speed);

break;

case 0x46: //ASCII 'F'

case 0x66: //ASCII 'f'

Serial.println(F("Setting both motors to forward"));

bIsForwardDir = true;

MoveAhead(speed, speed);

#pragma endregion MANUALCONTROL

break;

#pragma region WALL OFFSET TRACKING CASES

//left side wall tracking

case 0x4C: //ASCII 'L'

case 0x6C: //ASCII 'l'

StopBothMotors();

Serial.println(F("Setting Kp value"));

//consume CR/LF chars

while (Serial.available() > 0)

{

int byte = Serial.read();

mySerial.printf("consumed %d\n", byte);

}

while (!Serial.available())

{

}

Serial.readBytes(buff, bufflen);

mySerial.printf("%s\n", buff);

/* extract Kp */

token = strtok(buff, s);

Kp = atof(token);

/* extract Ki */

token = strtok(NULL, s);

Ki = atof(token);

/* extract Kd */

token = strtok(NULL, s);

Kd = atof(token);

/* extract Offset in cm */

token = strtok(NULL, s);

OffsetCm = atof(token);

mySerial.printf("Kp,Ki,Kd,OffsetCm = %2.2f, %2.2f, %2.2f, %2.2f\n",

Kp, Ki, Kd, OffsetCm);

TrackLeftWallOffset(Kp, Ki, Kd, OffsetCm);

break;

case 0x4D: //ASCII 'M'

case 0x6D: //ASCII 'm'

StopBothMotors();

Serial.println(F("Setting Kp value"));

//consume CR/LF chars

while (Serial.available() > 0)

{

int byte = Serial.read();

mySerial.printf("consumed %d\n", byte);

}

while (!Serial.available())

{

}

Serial.readBytes(buff, bufflen);

mySerial.printf("%s\n", buff);

/* extract Kp */

token = strtok(buff, s);

Kp = atof(token);

/* extract Ki */

token = strtok(NULL, s);

Ki = atof(token);

/* extract Kd */

token = strtok(NULL, s);

Kd = atof(token);

/* extract Offset in cm */

token = strtok(NULL, s);

OffsetCm = atof(token);

mySerial.printf("Kp,Ki,Kd,OffsetCm = %2.2f, %2.2f, %2.2f, %2.2f\n",

Kp, Ki, Kd, OffsetCm);

TrackRightWallOffset(Kp, Ki, Kd, OffsetCm);

break;

#pragma endregion WALL OFFSET TRACKING CASES

Default:

Serial.println(F("In Default Case: Stopping Motors!"));

MoveAhead(0, 0);

while (true)

{

}

}

}

}

}

}

}

void TrackLeftWallOffset(double kp, double ki, double kd, double offsetCm)

{

//Notes:

// 06/21/21 modified to do a turn, then straight, then track 0 steer val

elapsedMillis sinceLastComputeTime = 0;

double lastError = 0;

double lastInput = 0;

double lastIval = 0;

double lastDerror = 0;

bool bFirstTime = true;

double spinRateDPS = 45;

GetRequestedVL53l0xValues(VL53L0X_LEFT); //update LeftSteeringVal

mySerial.printf("Kp/Ki/Kd = %2.2f\t%2.2f\t%2.2f\n", kp, ki, kd);

//06/21/21 modified to do a turn, then straight, then track 0 steer val

double cutAngleDeg = WALL_OFFSET_TGTDIST_CM - (int)(Lidar_LeftCenter / 10.f);//positive inside, negative outside desired offset

//07/05/21 implement 15deg min cut angle

if (cutAngleDeg < 0 && abs(cutAngleDeg) < 15)

{

cutAngleDeg = -15;

}

else if (cutAngleDeg > 0 && cutAngleDeg < 15 )

{

cutAngleDeg = 15;

}

double SteerAngleDeg = GetSteeringAngle(LeftSteeringVal);

mySerial.printf("R/C/F dists = %d\t%d\t%d Steerval = %2.3f, SteerAngle = %2.2f, CutAngle = %2.2f\n",

Lidar_LeftRear, Lidar_LeftCenter, Lidar_LeftFront, LeftSteeringVal, SteerAngleDeg, cutAngleDeg);

double adjCutAngleDeg = 0;

uint16_t fudgeFactorMM = 0; //07/05/21 added so can change for inside vs outside starting condx

if (cutAngleDeg > 0) //robot inside desired offset distance

{

if (SteerAngleDeg > cutAngleDeg) // --> SteerAngleDeg also > 0

{

mySerial.printf("if (SteerAngleDeg > cutAngleDeg)\n");

SpinTurn(true, SteerAngleDeg - cutAngleDeg, spinRateDPS); //

}

else if (SteerAngleDeg < cutAngleDeg)// --> SteerAngleDeg could be < 0

{

if (SteerAngleDeg <= 0 ) //cutAngleDeg > 0, SteerAngleDeg <= 0

{

mySerial.printf("if (SteerAngleDeg <= 0)\n");

SpinTurn(false,cutAngleDeg - SteerAngleDeg, spinRateDPS); //null out SteerAngleDeg & then turn addnl cutAngleDeg

}

else //SteerAngleDeg < cutAngleDeg but still > 0

{

mySerial.printf("else\n");

SpinTurn(false,cutAngleDeg - SteerAngleDeg, spinRateDPS); //turn diff between SteerAngleDeg & cutAngleDeg

}

}

fudgeFactorMM = -100; //07/05/21 don't need fudge factor for inside start condx

}

else // cutAngleDeg < 0 --> robot outside desired offset distance

{

if (SteerAngleDeg > cutAngleDeg) // --> SteerAngleDeg may also be > 0

{

mySerial.printf("if (SteerAngleDeg > cutAngleDeg)\n");

SpinTurn(true, SteerAngleDeg - cutAngleDeg, spinRateDPS); //

}

else if (SteerAngleDeg < cutAngleDeg)// --> SteerAngleDeg must also be < 0

{

if (SteerAngleDeg <= 0) //cutAngleDeg > 0, SteerAngleDeg <= 0

{

mySerial.printf("if (SteerAngleDeg <= 0)\n");

SpinTurn(false, cutAngleDeg - SteerAngleDeg, spinRateDPS); //null out SteerAngleDeg & then turn addnl cutAngleDeg

}

else //SteerAngleDeg < cutAngleDeg but still > 0

{

mySerial.printf("else\n");

SpinTurn(false, cutAngleDeg - SteerAngleDeg, spinRateDPS); //turn diff between SteerAngleDeg & cutAngleDeg

}

}

fudgeFactorMM = 100; //07/05/21 need fudge factor for outside start condx

}

delay(1000);

//adjust so offset capture occurs at correct perpendicular offset

//double adjfactor = cos(PI * avgAppAngle / 180.f);

double adjfactor = cos(PI * cutAngleDeg / 180.f);

int adjOffsetMM = (int)(10 * (double)WALL_OFFSET_TGTDIST_CM / adjfactor);

//adjOffsetMM += 100; //fudge factor for distance measurements lagging behind robot's travel.

adjOffsetMM += fudgeFactorMM; //fudge factor for distance measurements lagging behind robot's travel.

//mySerial.printf("at approach start: steerval = %2.3f, adj cut angle = %2.2f, adjfactor = %2.3f, tgt dist = %d\n", avgSteerVal, avgAppAngle, adjfactor, adjOffsetMM);

mySerial.printf("at approach start: cut angle = %2.3f, adjfactor = %2.3f, tgt dist = %d\n", cutAngleDeg, adjfactor, adjOffsetMM);

//long int prev_res = Lidar_LeftFront - 10 * WALL_OFFSET_TGTDIST_CM; //neg for inside going out, pos for outside going in

long int prev_res = Lidar_LeftFront - adjOffsetMM; //neg for inside going out, pos for outside going in

long int res = prev_res;

mySerial.printf("At start - prev_res = %ld\n", prev_res);

mySerial.printf("Msec\tLFront\tLCtr\tLRear\tFront\tRear\tRes\tP_res\n");

//TIMSK5 = 0; //turn off TIMER5 interrupts

while (prev_res * res > 0) //sign change makes this < 0

{

prev_res = res;

MoveAhead(MOTOR_SPEED_QTR, MOTOR_SPEED_QTR);

while (!bTimeForNavUpdate)

{

}

bTimeForNavUpdate = false;

frontdistval = GetFrontDistCm();

res = Lidar_LeftFront - adjOffsetMM; //06/29/21 now adj for slant dist vs perp dist

mySerial.printf("%lu\t%d\t%d\t%d\t%d\t%d\t%ld\t%ld\n",

millis(),

Lidar_LeftFront, Lidar_LeftCenter, Lidar_LeftRear, frontdistval, Lidar_Rear, res, prev_res);

CheckForUserInput();

}

//now turn back the same (unadjusted) amount

mySerial.printf("At end - prev_res*res = %ld\n", prev_res*res);

mySerial.printf("correct back to parallel\n");

SpinTurn(!(cutAngleDeg < 0), abs(cutAngleDeg), spinRateDPS); //have to use abs() here, as cutAngleDeg can be neg

//sinceLastComputeTime = 0;

WallTrackSetPoint = 0; //moved here 6/22/21

//TIMSK5 |= (1 << OCIE5A);// enable timer compare interrupt

mySerial.printf("Msec\tFdir\tCdir\tRdir\tSteer\tSet\terror\tIval\tKp*err\tKi*Ival\tKd*Din\tOutput\tLspd\tRspd\n");

while (true)

{

CheckForUserInput(); //this is a bit recursive, but should still work (I hope)

//now using TIMER5 100 mSec interrupt for timing

if (bTimeForNavUpdate)

{

//sinceLastComputeTime -= WALL_TRACK_UPDATE_INTERVAL_MSEC;

bTimeForNavUpdate = false;

//GetRequestedVL53l0xValues(VL53L0X_LEFT); //now done in TIMER5 ISR

//have to weight value by both angle and wall offset

WallTrackSteerVal = LeftSteeringVal + (Lidar_LeftCenter - 10 * WALL_OFFSET_TGTDIST_CM) / 1000.f;

//update motor speeds, skipping bad values

if (!isnan(WallTrackSteerVal))

{

//10/12/20 now this executes every time, with interval controlled by timer ISR

PIDCalcs(WallTrackSteerVal, WallTrackSetPoint, TIMER5_INTERVAL_MSEC, lastError, lastInput, lastIval, lastDerror,

kp, ki, kd, WallTrackOutput);

int speed = 0;

int leftspeednum = MOTOR_SPEED_QTR + WallTrackOutput;

int rightspeednum = MOTOR_SPEED_QTR - WallTrackOutput;

rightspeednum = (rightspeednum <= MOTOR_SPEED_FULL) ? rightspeednum : MOTOR_SPEED_FULL;

rightspeednum = (rightspeednum > 0) ? rightspeednum : 0;

leftspeednum = (leftspeednum <= MOTOR_SPEED_FULL) ? leftspeednum : MOTOR_SPEED_FULL;

leftspeednum = (leftspeednum > 0) ? leftspeednum : 0;

MoveAhead(leftspeednum, rightspeednum);

mySerial.printf("%lu \t%d\t%d\t%d \t%2.2f\t%2.2f\t%2.2f\t%2.2f \t%2.2f\t%2.2f\t%2.2f \t%2.2f\t%d\t%d\n",

millis(),

Lidar_LeftFront, Lidar_LeftCenter, Lidar_LeftRear,

WallTrackSteerVal, WallTrackSetPoint, lastError, lastIval,

kp * lastError, ki * lastIval, kd * lastDerror,

WallTrackOutput, leftspeednum, rightspeednum);

}

}

}

}

void TrackRightWallOffset(double kp, double ki, double kd, double offsetCm)

{

//Notes:

// 06/21/21 modified to do a turn, then straight, then track 0 steer val

elapsedMillis sinceLastComputeTime = 0;

double lastError = 0;

double lastInput = 0;

double lastIval = 0;

double lastDerror = 0;

bool bFirstTime = true;

double spinRateDPS = 45;

GetRequestedVL53l0xValues(VL53L0X_RIGHT); //update RightSteeringVal = (Front - Rear)/100

mySerial.printf("Kp/Ki/Kd = %2.2f\t%2.2f\t%2.2f\n", kp, ki, kd);

//06/21/21 modified to do a turn, then straight, then track 0 steer val

double cutAngleDeg = WALL_OFFSET_TGTDIST_CM - (int)(Lidar_RightCenter / 10.f);//positive inside, negative outside desired offset

//07/05/21 implement 15deg min cut angle

if (cutAngleDeg < 0 && abs(cutAngleDeg) < 15)

{

cutAngleDeg = -15;

}

else if (cutAngleDeg > 0 && cutAngleDeg < 15)

{

cutAngleDeg = 15;

}

double SteerAngleDeg = GetSteeringAngle(RightSteeringVal);

mySerial.printf("R/C/F dists = %d\t%d\t%d Steerval = %2.3f, SteerAngle = %2.2f, CutAngle = %2.2f\n",

Lidar_RightRear, Lidar_RightCenter, Lidar_RightFront, RightSteeringVal, SteerAngleDeg, cutAngleDeg);

double adjCutAngleDeg = 0;

uint16_t fudgeFactorMM = 0; //07/05/21 added so can change for inside vs outside starting condx

if (cutAngleDeg > 0) //robot inside desired offset distance

{

if (SteerAngleDeg > cutAngleDeg) // --> SteerAngleDeg also > 0 (pointing away from wall)

{

mySerial.printf("if (SteerAngleDeg > cutAngleDeg)\n");

SpinTurn(false, SteerAngleDeg - cutAngleDeg, spinRateDPS); //

}

else if (SteerAngleDeg < cutAngleDeg)// --> SteerAngleDeg could be < 0

{

if (SteerAngleDeg <= 0) //cutAngleDeg > 0, SteerAngleDeg <= 0

{

mySerial.printf("if (SteerAngleDeg <= 0)\n");

//SpinTurn(false, cutAngleDeg - SteerAngleDeg, spinRateDPS); //null out SteerAngleDeg & then turn addnl cutAngleDeg

SpinTurn(true, cutAngleDeg - SteerAngleDeg, spinRateDPS); //null out SteerAngleDeg & then turn addnl cutAngleDeg

}

else //SteerAngleDeg < cutAngleDeg but still > 0

{

mySerial.printf("else\n");

//SpinTurn(false, cutAngleDeg - SteerAngleDeg, spinRateDPS); //turn diff between SteerAngleDeg & cutAngleDeg

SpinTurn(true, cutAngleDeg - SteerAngleDeg, spinRateDPS); //turn diff between SteerAngleDeg & cutAngleDeg

}

}

fudgeFactorMM = -100; //07/05/21 don't need fudge factor for inside start condx

}

else // cutAngleDeg < 0 --> robot outside desired offset distance

{

if (SteerAngleDeg > cutAngleDeg) // --> SteerAngleDeg may also be > 0

{

mySerial.printf("if (SteerAngleDeg > cutAngleDeg)\n");

SpinTurn(false, SteerAngleDeg - cutAngleDeg, spinRateDPS); //

}

else if (SteerAngleDeg < cutAngleDeg)// --> SteerAngleDeg must also be < 0

{

if (SteerAngleDeg <= 0) //cutAngleDeg > 0, SteerAngleDeg <= 0

{

mySerial.printf("if (SteerAngleDeg <= 0)\n");

//SpinTurn(false, cutAngleDeg - SteerAngleDeg, spinRateDPS); //null out SteerAngleDeg & then turn addnl cutAngleDeg

SpinTurn(true, cutAngleDeg - SteerAngleDeg, spinRateDPS); //null out SteerAngleDeg & then turn addnl cutAngleDeg

}

else //SteerAngleDeg < cutAngleDeg but still > 0

{

mySerial.printf("else\n");

//SpinTurn(false, cutAngleDeg - SteerAngleDeg, spinRateDPS); //turn diff between SteerAngleDeg & cutAngleDeg

SpinTurn(true, cutAngleDeg - SteerAngleDeg, spinRateDPS); //turn diff between SteerAngleDeg & cutAngleDeg

}

}

fudgeFactorMM = 100; //07/05/21 need fudge factor for outside start condx

}

//DEBUG!!

//mySerial.printf("Msec\tFront\tCtr\ttRear\tSteer\tAngle\n");

//double sumOfSteerVals = 0;

//for (size_t i = 0; i < 10; i++)

//{

// while (!bTimeForNavUpdate)

// {

// }

// bTimeForNavUpdate = false;

// //GetRequestedVL53l0xValues(VL53L0X_LEFT); //refresh steering value

// mySerial.printf("%lu\t%d\t%d\t%d\t%2.3f\t%2.2f\n",millis(),

// Lidar_RightFront, Lidar_RightCenter, Lidar_RightRear, RightSteeringVal, GetSteeringAngle(RightSteeringVal));

// sumOfSteerVals += RightSteeringVal;

// //delay(100);

//}

//double avgSteerVal = sumOfSteerVals / 10.f;

//double avgAppAngle = GetSteeringAngle(avgSteerVal);

//mySerial.printf("avg steerval = %2.3f, avg angle = %2.3f\n", avgSteerVal, avgAppAngle);

//DEBUG!!

delay(1000);

//adjust so offset capture occurs at correct perpendicular offset

//double adjfactor = cos(PI * avgAppAngle / 180.f);

double adjfactor = cos(PI * cutAngleDeg / 180.f);

int adjOffsetMM = (int)(10 * (double)WALL_OFFSET_TGTDIST_CM / adjfactor);

//adjOffsetMM += 100; //fudge factor for distance measurements lagging behind robot's travel.

adjOffsetMM += fudgeFactorMM; //fudge factor for distance measurements lagging behind robot's travel.

//mySerial.printf("at approach start: steerval = %2.3f, adj cut angle = %2.2f, adjfactor = %2.3f, tgt dist = %d\n", avgSteerVal, avgAppAngle, adjfactor, adjOffsetMM);

mySerial.printf("at approach start: cut angle = %2.3f, adjfactor = %2.3f, tgt dist = %d\n", cutAngleDeg, adjfactor, adjOffsetMM);

//long int prev_res = Lidar_RightFront - 10 * WALL_OFFSET_TGTDIST_CM; //neg for inside going out, pos for outside going in

long int prev_res = Lidar_RightFront - adjOffsetMM; //neg for inside going out, pos for outside going in

long int res = prev_res;

mySerial.printf("At start - prev_res = %ld\n", prev_res);

mySerial.printf("Msec\tLFront\tLCtr\tLRear\tFront\tRear\tRes\tP_res\n");

//TIMSK5 = 0; //turn off TIMER5 interrupts

while (prev_res * res > 0) //sign change makes this < 0

{

prev_res = res;

MoveAhead(MOTOR_SPEED_QTR, MOTOR_SPEED_QTR);

while (!bTimeForNavUpdate)

{

}

bTimeForNavUpdate = false;

frontdistval = GetFrontDistCm();

res = Lidar_RightFront - adjOffsetMM; //06/29/21 now adj for slant dist vs perp dist

mySerial.printf("%lu\t%d\t%d\t%d\t%d\t%d\t%ld\t%ld\n",

millis(),

Lidar_RightFront, Lidar_RightCenter, Lidar_RightRear, frontdistval, Lidar_Rear, res, prev_res);

CheckForUserInput();

}

//now turn back the same (unadjusted) amount

mySerial.printf("At end - prev_res*res = %ld\n", prev_res * res);

mySerial.printf("correct back to parallel\n");

//SpinTurn(!(cutAngleDeg < 0), abs(cutAngleDeg), spinRateDPS); //have to use abs() here, as cutAngleDeg can be neg

SpinTurn((cutAngleDeg < 0), abs(cutAngleDeg), spinRateDPS); //have to use abs() here, as cutAngleDeg can be neg

//sinceLastComputeTime = 0;

WallTrackSetPoint = 0; //moved here 6/22/21

//TIMSK5 |= (1 << OCIE5A);// enable timer compare interrupt

mySerial.printf("Msec\tFdir\tCdir\tRdir\tSteer\tSet\terror\tIval\tKp*err\tKi*Ival\tKd*Din\tOutput\tLspd\tRspd\n");

while (true)

{

CheckForUserInput(); //this is a bit recursive, but should still work (I hope)

//now using TIMER5 100 mSec interrupt for timing

if (bTimeForNavUpdate)

{

//sinceLastComputeTime -= WALL_TRACK_UPDATE_INTERVAL_MSEC;

bTimeForNavUpdate = false;

//GetRequestedVL53l0xValues(VL53L0X_LEFT); //now done in TIMER5 ISR

//have to weight value by both angle and wall offset

WallTrackSteerVal = RightSteeringVal + (Lidar_RightCenter - 10 * WALL_OFFSET_TGTDIST_CM) / 1000.f;

//update motor speeds, skipping bad values

if (!isnan(WallTrackSteerVal))

{

//10/12/20 now this executes every time, with interval controlled by timer ISR

//PIDCalcs(WallTrackSteerVal, WallTrackSetPoint, TIMER5_INTERVAL_MSEC, lastError, lastInput, lastIval, lastDerror,

// kp, ki, kd, WallTrackOutput);

PIDCalcs(WallTrackSteerVal, WallTrackSetPoint, TIMER5_INTERVAL_MSEC, lastError, lastInput, lastIval, lastDerror,

kp, ki, kd, WallTrackOutput);

int speed = 0;

//07/05/21 reverse signs for right side tracking

//int leftspeednum = MOTOR_SPEED_QTR + WallTrackOutput;

//int rightspeednum = MOTOR_SPEED_QTR - WallTrackOutput;

int leftspeednum = MOTOR_SPEED_QTR - WallTrackOutput;

int rightspeednum = MOTOR_SPEED_QTR + WallTrackOutput;

rightspeednum = (rightspeednum <= MOTOR_SPEED_FULL) ? rightspeednum : MOTOR_SPEED_FULL;

rightspeednum = (rightspeednum > 0) ? rightspeednum : 0;

leftspeednum = (leftspeednum <= MOTOR_SPEED_FULL) ? leftspeednum : MOTOR_SPEED_FULL;

leftspeednum = (leftspeednum > 0) ? leftspeednum : 0;

MoveAhead(leftspeednum, rightspeednum);

//mySerial.printf("%lu \t%d\t%d\t%d \t%2.2f\t%2.2f\t%2.2f\t%2.2f \t%2.2f\t%2.2f\t%2.2f \t%2.2f\t%d\t%d\n",

// millis(),

// Lidar_RightFront, Lidar_RightCenter, Lidar_RightRear,

// WallTrackSteerVal, WallTrackSetPoint, lastError, lastIval,

// kp * lastError, ki * lastIval, kd * lastDerror,

// WallTrackOutput, leftspeednum, rightspeednum);

mySerial.printf("%lu \t%d\t%d\t%d \t%2.2f\t%2.2f\t%2.2f\t%2.2f \t%2.2f\t%2.2f\t%2.2f \t%2.2f\t%d\t%d\n",

millis(),

Lidar_RightFront, Lidar_RightCenter, Lidar_RightRear,

-WallTrackSteerVal, WallTrackSetPoint, lastError, lastIval,

kp * lastError, ki * lastIval, kd * lastDerror,

WallTrackOutput, leftspeednum, rightspeednum);

}

}

}

}

#pragma region MOTOR SUPPORT

//09/08/20 modified for DRV8871 motor driver

void MoveReverse(int leftspeednum, int rightspeednum)

{

//Purpose: Move in reverse direction continuously - companion to MoveAhead()

//ProvEnA_Pinnce: G. Frank Paynter 09/08/18

//Inputs:

// leftspeednum = integer denoting speed (0=stop, 255 = full speed)

// rightspeednum = integer denoting speed (0=stop, 255 = full speed)

//Outputs: both drive Motors energized with the specified speed

//Plan:

// Step 1: Set reverse direction for both wheels

// Step 2: Run both Motors at specified speeds

//Notes:

// 01/22/20 now using Adafruit DRV8871 drivers

//Step 1: Set reverse direction and speed for both wheels

SetLeftMotorDirAndSpeed(REV_DIR, leftspeednum);

SetRightMotorDirAndSpeed(REV_DIR, rightspeednum);

}

//09/08/20 modified for DRV8871 motor driver

void MoveAhead(int leftspeednum, int rightspeednum)

{

//Purpose: Move ahead continuously

//ProvEnA_Pinnce: G. Frank Paynter and Danny Frank 01/24/2014

//Inputs:

// leftspeednum = integer denoting speed (0=stop, 255 = full speed)

// rightspeednum = integer denoting speed (0=stop, 255 = full speed)

//Outputs: both drive Motors energized with the specified speed

//Plan:

// Step 1: Set forward direction for both wheels

// Step 2: Run both Motors at specified speeds

//Notes:

// 01/22/20 now using Adafruit DRV8871 drivers

//mySerial.printf("InMoveAhead(%d,%d)\n", leftspeednum, rightspeednum);

//Step 1: Set forward direction and speed for both wheels

SetLeftMotorDirAndSpeed(true, leftspeednum);

SetRightMotorDirAndSpeed(true, rightspeednum);

}

//09/08/10 modified for DRV8871 motor driver

void StopLeftMotors()

{

analogWrite(In1_Left, MOTOR_SPEED_OFF);

analogWrite(In2_Left, MOTOR_SPEED_OFF);

}

void StopRightMotors()

{

analogWrite(In1_Right, MOTOR_SPEED_OFF);

analogWrite(In2_Right, MOTOR_SPEED_OFF);

}

//09/08/20 added bool bisFwd param for DRV8871 motor driver

void RunBothMotors(bool bisFwd, int leftspeednum, int rightspeednum)

{

//Purpose: Run both Motors at left/rightspeednum speeds

//Inputs:

// speednum = speed value (0 = OFF, 255 = full speed)

//Outputs: Both Motors run for timesec seconds at speednum speed

//Plan:

// Step 1: Apply drive to both wheels

//Notes:

// 01/14/15 - added left/right speed offset for straightness compensation

// 01/22/15 - added code to restrict fast/slow values

// 01/24/15 - revised for continuous run - no timing

// 01/26/15 - speednum modifications moved to UpdateWallFollowmyMotorspeeds()

// 12/07/15 - chg args from &int to int

//Step 1: Apply drive to both wheels

//DEBUG!!

//mySerial.printf("In RunBothMotors(%s, %d,%d)\n", bisFwd? "FWD":"REV", leftspeednum, rightspeednum);

//DEBUG!!

SetLeftMotorDirAndSpeed(bisFwd, leftspeednum);

SetRightMotorDirAndSpeed(bisFwd, rightspeednum);

}

void RunBothMotorsBidirectional(int leftspeed, int rightspeed)

{

//Purpose: Accommodate the need for independent bidirectional wheel motion

//Inputs:

// leftspeed - integer denoting left wheel speed. Positive value is fwd, negative is rev

// rightspeed - integer denoting right wheel speed. Positive value is fwd, negative is rev

//Outputs:

// left/right wheel motors direction and speed set as appropriate

//Plan:

// Step1: Set left wheel direction and speed

// Step2: Set right wheel direction and speed

//Step1: Set left wheel direction and speed

//DEBUG!!

//mySerial.printf("In RunBothMotorsBidirectional(%d, %d)\n", leftspeed, rightspeed);

if (leftspeed < 0)

{

SetLeftMotorDirAndSpeed(false, -leftspeed); //neg value ==> reverse

}

else

{

SetLeftMotorDirAndSpeed(true, leftspeed); //pos or zero value ==> fwd

}

//Step2: Set right wheel direction and speed

if (rightspeed < 0)

{

SetRightMotorDirAndSpeed(false, -rightspeed); //neg value ==> reverse

}

else

{

SetRightMotorDirAndSpeed(true, rightspeed); //pos or zero value ==> fwd

}

}

//09/08/20 added bool bisFwd param for DRV8871 motor driver

void RunBothMotorsMsec(bool bisFwd, int timeMsec, int leftspeednum, int rightspeednum)

{

//Purpose: Run both Motors for timesec seconds at speednum speed

//Inputs:

// timesec = time in seconds to run the Motors

// speednum = speed value (0 = OFF, 255 = full speed)

//Outputs: Both Motors run for timesec seconds at speednum speed

//Plan:

// Step 1: Apply drive to both wheels

// Step 2: Delay timsec seconds

// Step 3: Remove drive from both wheels.

//Notes:

// 01/14/15 - added left/right speed offset for straightness compensation

// 01/22/15 - added code to restrict fast/slow values

// 11/25/15 - rev to use motor driver class object

// 09/08/20 added bool bisFwd param for DRV8871 motor driver

RunBothMotors(bisFwd, leftspeednum, rightspeednum);

//Step 2: Delay timsec seconds

delay(timeMsec);

//Step3: Stop motors added 04/12/21

StopBothMotors();

}

//11/25/15 added for symmetry ;-).

void StopBothMotors()

{

StopLeftMotors();

StopRightMotors();

}

void SetLeftMotorDirAndSpeed(bool bIsFwd, int speed)

{

//mySerial.printf("SetLeftMotorDirAndSpeed(%d,%d)\n", bIsFwd, speed);

#ifndef NO_MOTORS

if (bIsFwd)

{

digitalWrite(In1_Left, LOW);

analogWrite(In2_Left, speed);

//mySerial.printf("In TRUE block of SetLeftMotorDirAndSpeed(%s, %d)\n",

// (bIsFwd == true) ? "true" : "false", speed);

}

else

{

//mySerial.printf("In FALSE block of SetLeftMotorDirAndSpeed(%s, %d)\n",

// (bIsFwd == true) ? "true" : "false", speed);

digitalWrite(In2_Left, LOW);

analogWrite(In1_Left, speed);

}

#endif // !NO_MOTORS

}

void SetRightMotorDirAndSpeed(bool bIsFwd, int speed)

{

//mySerial.printf("In SetRightMotorDirAndSpeed(%s, %d)\n",

// (bIsFwd == true) ? "true" : "false", speed);

#ifndef NO_MOTORS

if (bIsFwd)

{

//mySerial.printf("In TRUE block of SetRighttMotorDirAndSpeed(%s, %d)\n",

// (bIsFwd == true) ? "true" : "false", speed);

digitalWrite(In1_Right, LOW);

analogWrite(In2_Right, speed);

}

else

{

//mySerial.printf("In FALSE block of SetRightMotorDirAndSpeed(%s, %d)\n",

// (bIsFwd == true) ? "true" : "false", speed);

digitalWrite(In2_Right, LOW);

analogWrite(In1_Right, speed);

}

#endif // !NO_MOTORS

}

#pragma endregion Motor Support Functions

#pragma region MPU5060 Support

float UpdateIMUHdgValDeg()

{

//Purpose: Get latest yaw (heading) value from IMU

//Inputs: None. This function should only be called after mpu.dmpPacketAvailable() returns TRUE

//Outputs:

// returns true if successful, otherwise false

// IMUHdgValDeg updated on success

//Plan:

//Step1: check for overflow and reset the FIFO if it occurs. In this case, wait for new packet

//Step2: read all available packets to get to latest data

//Step3: update IMUHdgValDeg with latest value

//Notes:

// 10/08/19 changed return type to boolean

// 10/08/19 no longer need mpuIntStatus

// 10/21/19 completely rewritten to use Homer's algorithm

// 05/05/20 changed return type to float vs bool.

bool retval = false;

int flag = GetCurrentFIFOPacket(fifoBuffer, packetSize, MAX_GETPACKET_LOOPS); //get the latest mpu packet

if (flag != 0) //0 = error exit, 1 = normal exit, 2 = recovered from an overflow

{

// display Euler angles in degrees

mpu.dmpGetQuaternion(&q, fifoBuffer);

mpu.dmpGetGravity(&gravity, &q);

mpu.dmpGetYawPitchRoll(ypr, &q, &gravity);

//compute the yaw value

IMUHdgValDeg = ypr[0] * 180 / M_PI;

retval = true;

}

//return retval;

return IMUHdgValDeg;//05/05/20 now returns updated value for use convenience

}

uint8_t GetCurrentFIFOPacket(uint8_t* data, uint8_t length, uint16_t max_loops)

{

mpu.resetFIFO();

delay(1);

//int countloop = 0;

fifoCount = mpu.getFIFOCount();

GetPacketLoopCount = 0;

//mySerial.printf("In GetCurrentFIFOPacket: before loop fifoC = %d\t", fifoCount);

while (fifoCount < packetSize && GetPacketLoopCount < max_loops)

{

GetPacketLoopCount++;

fifoCount = mpu.getFIFOCount();

delay(2);

}

//mySerial.printf("In GetCurrentFIFOPacket: after loop fifoC = %d, loop count = %d\n", fifoCount, GetPacketLoopCount);

if (GetPacketLoopCount >= max_loops)

{

return 0;

}

//if we get to here, there should be exactly one packet in the FIFO

mpu.getFIFOBytes(data, packetSize);

return 1;

}

#pragma endregion MPU5060 Support

#pragma region HDG_BASED_TURN_SUPPORT

float GetHdgMatchVal(float tgt_deg, float cur_deg)

{

//Purpose: Compute the match ratio between two compass headings

//Inputs:

// tgt_deg = float representing target heading in +/-180 range

// IMUHdgValDeg = float representing sensor yaw value in +/-180 deg range

//Outputs:

// returns result of 1 - abs(Tgt_deg - Hdg_deg)/180, all angles in 0-360 deg range

//Plan:

// Step1: convert both inputs to 0-360 deg range

// Step2: compute match ratio

//Notes:

// formula from https://gis.stackexchange.com/questions/129954/comparing-compass-bearings

//Step1: convert both inputs to 0-360 deg range

float tgthdg = (tgt_deg < 0) ? tgt_deg + 360 : tgt_deg;

float curhdg = (cur_deg < 0) ? cur_deg + 360 : cur_deg;

//Step2: compute match ratio

float match_ratio = 1 - abs(tgthdg - curhdg) / 180;

//DEBUG!!

//mySerial.printf("tgt\tcur\tmatch = %4.2f\t%4.2f\t%1.3f\n", tgthdg, curhdg, match_ratio);

//DEBUG!!

return abs(match_ratio);

}

bool SpinTurn(bool b_ccw, float numDeg, float degPersec) //04/25/21 added turn-rate arg (default = TURN_RATE_TARGET_DEGPERSEC)

{

//Purpose: Make a numDeg CW or CCW 'spin' turn

//Inputs:

// b_ccw - True if turn is to be ccw, false otherwise

// numDeg - angle to be swept out in the turn

// ROLLING_TURN_MAX_SEC_PER_DEG = const used to generate timeout proportional to turn deg

// IMUHdgValDeg = IMU heading value updated by UpdateIMUHdgValDeg() //11/02/20 now updated in ISR

// degPerSec = float value denoting desired turn rate

//Plan:

// Step1: Get current heading as starting point

// Step2: Disable TIMER5 interrupts

// Step3: Compute new target value & timeout value

// Step4: Run motors until target reached, using inline PID algorithm to control turn rate

// Step5: Re-enable TIMER5 interrupts

//Notes:

// 06/06/21 we-written to remove PID library - now uses custom 'PIDCalcs()' function

// 06/06/21 added re-try for 180.00 return from IMU - could be bad value

// 06/11/21 added code to correct dHdg errors due to 179/-179 transition & bad IMU values

// 06/12/21 cleaned up & commented out debug code

float tgt_deg;

float timeout_sec;

bool bDoneTurning = false;

bool bTimedOut = false;

bool bResult = true; //04/21/20 added so will be only one exit point

//DEBUG!!

mySerial.printf("In SpinTurn(%s, %2.2f, %2.2f)\n", b_ccw == TURNDIR_CCW ? "CCW" : "CW", numDeg, degPersec);

//DEBUG!!

//mySerial.printf("TurnRatePID started with Kp/Ki/Kd = %2.1f,%2.1f,%2.1f, SampleTime(mSec) = %d\n",

// TurnRate_Kp, TurnRate_Ki, TurnRate_Kd, TURN_RATE_UPDATE_INTERVAL_MSEC);

//no need to continue if the IMU isn't available

if (!dmpReady)

{

return false;

}

//Step1: Get current heading as starting point

//06/06/21 it is possible for IMU to return 180.00 on failure

//so try again. If it really IS 180, then

//it will eventually time out and go on

int retries = 0;

if (IMUHdgValDeg == 180.f && retries < 5)

{

//DEBUG!!

mySerial.printf("Got 180.00 exactly from IMU - retrying...\n");

//DEBUG!!

UpdateIMUHdgValDeg();

retries++;

delay(30);

}

//Step2: Compute new target value & timeout value

timeout_sec = 3 * numDeg / degPersec; //05/29/21 rev to use new turn rate parmeter

//05/17/20 limit timeout_sec to 1 sec or more

timeout_sec = (timeout_sec < 1) ? 1.f : timeout_sec;

UpdateIMUHdgValDeg();

//12/05/19 added #define back in to manage which direction increases yaw values

#ifdef MPU6050_CCW_INCREASES_YAWVAL

tgt_deg = b_ccw ? IMUHdgValDeg + numDeg : IMUHdgValDeg - numDeg;

#else

tgt_deg = b_ccw ? IMUHdgValDeg - numDeg : IMUHdgValDeg + numDeg;

#endif // MPU6050_CCW_INCREASES_YAWVAL

//correct for -180/180 transition

if (tgt_deg < -180)

{

tgt_deg += 360;

}

//07/29/19 bugfix

if (tgt_deg > 180)

{

tgt_deg -= 360;

}

//DEBUG!!

mySerial.printf("Init hdg = %4.2f deg, Turn = %4.2f deg, tgt = %4.2f deg, timeout = %4.2f sec\n\n",

IMUHdgValDeg, numDeg, tgt_deg, timeout_sec);

//DEBUG!!

double curHdgMatchVal = 0;

//09/08/18 added to bolster end-of-turn detection

float prevHdgMatchVal = 0;

float matchSlope = 0;

//Step2: Disable TIMER5 interrupts

TIMSK5 = 0; //disable timer compare interrupt

//Step3: Run motors until target reached, using PID algorithm to control turn rate

Prev_HdgDeg = IMUHdgValDeg; //06/10/21 synch Prev_HdgDeg & IMUHdgValDeg just before entering loop

//DEBUG!!

//mySerial.printf("Just before while() loop: hdg/prvhdg = %2.2f\t%2.2f\n\n", IMUHdgValDeg, Prev_HdgDeg);

//mySerial.printf("Msec\tHdg\tPrvHdg\tDhdg\trate\tSet\terror\tKp*err\tKi*err\tKd*Din\tOutput\n");

//DEBUG!!

elapsedMillis sinceLastTimeCheck = 0;

elapsedMillis sinceLastComputeTime = 0;

double lastError = 0;

double lastInput = 0;

double lastIval = 0;

double lastDerror = 0;

bool bFirstIMUHdg = true;

while (!bDoneTurning && !bTimedOut)

{

//11/06/20 now just loops between ISR hits

CheckForUserInput();

//runs every 30mSec

if (sinceLastComputeTime >= TURN_RATE_UPDATE_INTERVAL_MSEC)

{

sinceLastComputeTime -= TURN_RATE_UPDATE_INTERVAL_MSEC;

UpdateIMUHdgValDeg(); //update IMUHdgValDeg

double dHdg = IMUHdgValDeg - Prev_HdgDeg;

if (dHdg > 180)

{

dHdg -= 360;

mySerial.printf("dHdg > 180 (%2.2f - %2.2f) - subtracting 360\n", IMUHdgValDeg, Prev_HdgDeg);

}

else if (dHdg < -180)

{

dHdg += 360;

mySerial.printf("dHdg < -180 (%2.2f - %2.2f) - adding 360\n", IMUHdgValDeg, Prev_HdgDeg);

}

//watch for turn rates that are wildly off

double rate = abs(1000 * dHdg / TURN_RATE_UPDATE_INTERVAL_MSEC);

if (rate > 3 * degPersec)

{

//DEBUG!!

mySerial.printf("hdg/prevhdg/dHdg/rate = %2.2f\t%2.2f\t%2.2f\t%2.2f, excessive rate - replacing with %2.2f\n", IMUHdgValDeg, Prev_HdgDeg, dHdg, rate, degPersec);

//DEBUG!!

rate = degPersec;

}

//06/11/21 don't do calcs first time through, as Prev_HdgDeg isn't valid yet

if (bFirstIMUHdg)

{

bFirstIMUHdg = false;

Prev_HdgDeg = IMUHdgValDeg; //re-synch prev to curr hdg for next time

}

else

{

PIDCalcs(rate, degPersec, TURN_RATE_UPDATE_INTERVAL_MSEC, lastError, lastInput, lastIval, lastDerror, TurnRate_Kp, TurnRate_Ki, TurnRate_Kd, TurnRatePIDOutput);

int speed = 0;

(TurnRatePIDOutput > MOTOR_SPEED_MAX) ? speed = MOTOR_SPEED_MAX : speed = (int)TurnRatePIDOutput;

(TurnRatePIDOutput <= MOTOR_SPEED_LOW) ? speed = MOTOR_SPEED_LOW : speed = (int)TurnRatePIDOutput;

SetLeftMotorDirAndSpeed(!b_ccw, speed);

SetRightMotorDirAndSpeed(b_ccw, speed);

//check for nearly there and all the way there

curHdgMatchVal = GetHdgMatchVal(tgt_deg, IMUHdgValDeg);

matchSlope = curHdgMatchVal - prevHdgMatchVal;

prevHdgMatchVal = curHdgMatchVal;

//DEBUG!!

//mySerial.printf("%lu\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%d\n",

// millis(),

// IMUHdgValDeg,

// Prev_HdgDeg,

// dHdg,

// rate,

// degPersec,

// lastError,

// TurnRate_Kp * lastError,

// TurnRate_Ki * lastIval,

// TurnRate_Kd * lastDerror,

// speed);

//DEBUG!!

Prev_HdgDeg = IMUHdgValDeg; //re-synch prev to curr hdg for next time

//look for full match

bDoneTurning = (curHdgMatchVal >= HDG_FULL_MATCH_VAL

|| (curHdgMatchVal >= HDG_MIN_MATCH_VAL && matchSlope < -0.1)); //have to use < vs <= as slope == 0 at start

}

}

bTimedOut = (sinceLastTimeCheck > timeout_sec * 1000);

if (bTimedOut)

{

//DEBUG!!

mySerial.printf("timed out with yaw = %3.2f, tgt = %3.2f, and match = %1.3f\n", IMUHdgValDeg, tgt_deg, curHdgMatchVal);

//DEBUG!!

bResult = false;

}

}

//DEBUG!!

mySerial.printf("%lu: Exiting SpinTurn() at %3.2f deg\n", millis(), IMUHdgValDeg);

//DEBUG!!

//Step4: Re-enable TIMER5 interrupts

TIMSK5 |= (1 << OCIE5A);// enable timer compare interrupt

StopBothMotors();

//delay(1000); //added 04/27/21 for debug

return bResult;

}

//bool SpinTurnToSteerVal(bool b_ccw, float tgtSteerVal, float degPersec) //04/25/21 added turn-rate arg (default = TURN_RATE_TARGET_DEGPERSEC)

//{

// //Purpose: Make a rate-controlled CW or CCW 'spin' turn to a desired steering value

// //Inputs:

// // b_ccw - True if turn is to be ccw, false otherwise

// // steerval - steering value to be met

// // ROLLING_TURN_MAX_SEC_PER_DEG = const used to generate timeout proportional to turn deg

// // IMUHdgValDeg = IMU heading value updated by UpdateIMUHdgValDeg() //11/02/20 now updated in ISR

// // degPerSec = float value denoting desired turn rate

// //Plan:

// // Step1: Get current heading as starting point

// // Step2: Disable TIMER5 interrupts

// // Step4: Run motors until target steering value reached, using inline PID algorithm to control turn rate

// // Step5: Re-enable TIMER5 interrupts

// //Notes:

// // copied from SpinTurn() and modifed to terminate on steering value

//

// //float tgt_deg;

// float timeout_sec;

// bool bDoneTurning = false;

// bool bTimedOut = false;

// bool bResult = true; //04/21/20 added so will be only one exit point

//

// ////DEBUG!!

// //mySerial.printf("In SpinTurn(%s, %2.2f, %2.2f)\n", b_ccw == TURNDIR_CCW ? "CCW" : "CW", numDeg, degPersec);

// ////DEBUG!!

// mySerial.printf("TurnRatePID started with Kp/Ki/Kd = %2.1f,%2.1f,%2.1f, SampleTime(mSec) = %d\n",

// TurnRate_Kp, TurnRate_Ki, TurnRate_Kd, TURN_RATE_UPDATE_INTERVAL_MSEC);

//

// //no need to continue if the IMU isn't available

// if (!dmpReady)

// {

// return false;

// }

//

// //Step1: Get current heading as starting point

// //06/06/21 it is possible for IMU to return 180.00 on failure

// //so try again. If it really IS 180, then

// //it will eventually time out and go on

// int retries = 0;

// if (IMUHdgValDeg == 180.f && retries < 5)

// {

// //DEBUG!!

// //mySerial.printf("Got 180.00 exactly from IMU - retrying...\n");

// //DEBUG!!

// UpdateIMUHdgValDeg();

// retries++;

// delay(30);

// }

//

// ////Step2: Compute new target value & timeout value

// //timeout_sec = 3 * numDeg / degPersec; //05/29/21 rev to use new turn rate parmeter

//

// ////05/17/20 limit timeout_sec to 1 sec or more

// //timeout_sec = (timeout_sec < 1) ? 1.f : timeout_sec;

//

// UpdateIMUHdgValDeg();

//

//// //12/05/19 added #define back in to manage which direction increases yaw values

////#ifdef MPU6050_CCW_INCREASES_YAWVAL

//// tgt_deg = b_ccw ? IMUHdgValDeg + numDeg : IMUHdgValDeg - numDeg;

////#else

//// tgt_deg = b_ccw ? IMUHdgValDeg - numDeg : IMUHdgValDeg + numDeg;

////

////#endif // MPU6050_CCW_INCREASES_YAWVAL

////

//// //correct for -180/180 transition

//// if (tgt_deg < -180)

//// {

//// tgt_deg += 360;

//// }

////

//// //07/29/19 bugfix

//// if (tgt_deg > 180)

//// {

//// tgt_deg -= 360;

//// }

//

// //DEBUG!!

// //mySerial.printf("Init hdg = %4.2f deg, Turn = %4.2f deg, tgt = %4.2f deg, timeout = %4.2f sec\n\n",

// // IMUHdgValDeg, numDeg, tgt_deg, timeout_sec);

// //DEBUG!!

//

// //float curHdgMatchVal = 0;

//

// ////09/08/18 added to bolster end-of-turn detection

// //float prevHdgMatchVal = 0;

// //float matchSlope = 0;

//

//

// //Step2: Disable TIMER5 interrupts

// TIMSK5 = 0; //disable timer compare interrupt

//

// //Step3: Run motors until target reached, using PID algorithm to control turn rate

// Prev_HdgDeg = IMUHdgValDeg; //06/10/21 synch Prev_HdgDeg & IMUHdgValDeg just before entering loop

//

// //DEBUG!!

// //mySerial.printf("Just before while() loop: hdg/prvhdg = %2.2f\t%2.2f\n\n", IMUHdgValDeg, Prev_HdgDeg);

//

// //mySerial.printf("Msec\tHdg\tPrvHdg\tDhdg\trate\tSet\terror\tKp*err\tKi*err\tKd*Din\tOutput\n");

// //DEBUG!!

//

// elapsedMillis sinceLastTimeCheck = 0;

// elapsedMillis sinceLastComputeTime = 0;

// double lastError = 0;

// double lastInput = 0;

// double lastIval = 0;

// double lastDerror = 0;

// bool bFirstIMUHdg = true;

//

// //while (!bDoneTurning && !bTimedOut)

// while (!bDoneTurning)

// {

// //11/06/20 now just loops between ISR hits

// CheckForUserInput();

//

// //runs every 30mSec

// if (sinceLastComputeTime >= TURN_RATE_UPDATE_INTERVAL_MSEC)

// {

// sinceLastComputeTime -= TURN_RATE_UPDATE_INTERVAL_MSEC;

//

// UpdateIMUHdgValDeg(); //update IMUHdgValDeg

//

// double dHdg = IMUHdgValDeg - Prev_HdgDeg;

// if (dHdg > 180)

// {

// dHdg -= 360;

// mySerial.printf("dHdg > 180 - subtracting 360\n");

// }

// else if (dHdg < -180)

// {

// dHdg += 360;

// mySerial.printf("dHdg < -180 - adding 360\n");

// }

//

// //watch for turn rates that are wildly off

// double rate = abs(1000 * dHdg / TURN_RATE_UPDATE_INTERVAL_MSEC);

// if (rate > 3 * degPersec)

// {

// //DEBUG!!

// //mySerial.printf("hdg/prevhdg/dHdg/rate = %2.2f\t%2.2f\t%2.2f\t%2.2f, excessive rate - replacing with %2.2f\n", IMUHdgValDeg, Prev_HdgDeg, dHdg, rate, degPersec);

// //DEBUG!!

// rate = degPersec;

// }

//

// //06/11/21 don't do calcs first time through, as Prev_HdgDeg isn't valid yet

// if (bFirstIMUHdg)

// {

// bFirstIMUHdg = false;

// Prev_HdgDeg = IMUHdgValDeg; //re-synch prev to curr hdg for next time

// }

// else

// {

// PIDCalcs(rate, degPersec, TURN_RATE_UPDATE_INTERVAL_MSEC, lastError, lastInput, lastIval, lastDerror, TurnRate_Kp, TurnRate_Ki, TurnRate_Kd, TurnRatePIDOutput);

//

// int speed = 0;

//

// (TurnRatePIDOutput > MOTOR_SPEED_MAX) ? speed = MOTOR_SPEED_MAX : speed = (int)TurnRatePIDOutput;

// (TurnRatePIDOutput <= MOTOR_SPEED_LOW) ? speed = MOTOR_SPEED_LOW : speed = (int)TurnRatePIDOutput;

//

// SetLeftMotorDirAndSpeed(!b_ccw, speed);

// SetRightMotorDirAndSpeed(b_ccw, speed);

//

// //check for nearly there and all the way there

// //curHdgMatchVal = GetHdgMatchVal(tgt_deg, IMUHdgValDeg);

// //matchSlope = curHdgMatchVal - prevHdgMatchVal;

// //prevHdgMatchVal = curHdgMatchVal;

//

// //DEBUG!!

// mySerial.printf("%lu\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%d\n",

// millis(),

// IMUHdgValDeg,

// Prev_HdgDeg,

// dHdg,

// rate,

// degPersec,

// lastError,

// TurnRate_Kp * lastError,

// TurnRate_Ki * lastIval,

// TurnRate_Kd * lastDerror,

// speed);

// //DEBUG!!

//

// Prev_HdgDeg = IMUHdgValDeg; //re-synch prev to curr hdg for next time

//

// //look for full match

// GetRequestedVL53l0xValues(VL53L0X_ALL);

// bDoneTurning = (abs(LeftSteeringVal - tgtSteerVal) <= RATIO_TURN_MATCH_THRESHOLD);

// }

// }

//

// //bTimedOut = (sinceLastTimeCheck > timeout_sec * 1000);

//

// //if (bTimedOut)

// //{

// // //DEBUG!!

// // //mySerial.printf("timed out with yaw = %3.2f, tgt = %3.2f, and match = %1.3f\n", IMUHdgValDeg, tgt_deg, curHdgMatchVal);

// // //DEBUG!!

//

// // bResult = false;

// //}

// }

//

// //DEBUG!!

// //mySerial.printf("%lu: Exiting SpinTurn() at %3.2f deg\n", millis(), IMUHdgValDeg);

// //DEBUG!!

//

////Step4: Re-enable TIMER5 interrupts

// TIMSK5 |= (1 << OCIE5A);// enable timer compare interrupt

//

// StopBothMotors();

// delay(1000); //added 04/27/21 for debug

// return bResult;

//}

void PIDCalcs(double input, double setpoint, uint16_t sampleTime, double& lastError, double& lastInput, double& lastIval, double& lastDerror, double Kp, double Ki, double Kd, double& output)

{

//Purpose: Encapsulate PID algorithm so can get rid of PID library. Library too cumbersome and won't synch with TIMER5 ISR

//Inputs:

// input = double denoting current input value (turn rate, speed, whatever)

// setpoint = double denoting desired setpoint in same units as input

// sampleTime = int denoting sample time to be used in calcs.

// lastError = ref to double denoting error saved from prev calc

// lastInput = ref to double denoting input saved from prev calc

// Kp/Ki/Kd = doubles denoting PID values to be used for calcs

// Output = ref to double denoting output from calc

double error = setpoint - input;

double dInput = (input - lastInput);

lastIval += (error);

double dErr = (error - lastError);

//mySerial.printf("PIDCalcs: error/dInput/lastIval/dErr/kp/ki/kd = %2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\t%2.2f\n", error, dInput, lastIval, dErr,

// Kp,Ki,Kd);

/*Compute PID Output*/

output = Kp * error + Ki * lastIval + Kd * dErr;

/*Remember some variables for next time*/

lastError = error;

lastInput = input;

lastDerror = dErr;

}

#pragma endregion HDG_BASED_TURN_SUPPORT

bool GetRequestedVL53l0xValues(VL53L0X_REQUEST which)

{

//Purpose: Obtain VL53L0X ToF sensor data from Teensy sensor handler

//Inputs:

// which = VL53L0X_REQUEST value denoting which combination of value to retrieve

// VL53L0X_CENTERS_ONLY -> Just the left/right center sensor values

// VL53L0X_RIGHT -> All three right sensor values, in front/center/rear order

// VL53L0X_LEFT -> All three left sensor values, in front/center/rear order

// VL53L0X_ALL -> All seven sensor values, in left/right front/center/rear/rear order

// VL53L0X_REAR_ONLY -> added 10/24/20 Just the rear sensor reading

//Outputs:

// Requested sensor values, obtained via I2C from the VL53L0X sensor handler

// Returns TRUE if data retrieval successful, otherwise FALSE

//Plan:

// Step1: Send request to VL53L0X handler

// Step2: get the requested data

//Notes:

// Copied from FourWD_WallE2_V4.ino's IsIRBeamAvail() and adapted

// 08/05/20 added a VL53L0X_ALL request type

// 01/24/21 added error detection/reporting

//Step1: Send request to VL53L0X handler

//DEBUG!!

//mySerial.printf("Sending %d to slave\n", which);

//DEBUG!!

//mySerial.printf("In GetRequestedVL53l0xValues(%d)\n", (int)which);

Wire.beginTransmission(VL53L0X_I2C_SLAVE_ADDRESS);

I2C_writeAnything((uint8_t)which);

Wire.endTransmission();

//Step2: get the requested data

int readResult = 0;

int data_size = 0;

switch (which)

{

case VL53L0X_READYCHECK: //11/10/20 added to prevent bad reads during Teensy setup()

Wire.requestFrom(VL53L0X_I2C_SLAVE_ADDRESS, (int)(sizeof(bVL53L0X_TeensyReady)));

readResult = I2C_readAnything(bVL53L0X_TeensyReady);

break;

case VL53L0X_CENTERS_ONLY:

//just two data values needed here

data_size = 2 * sizeof(int);

Wire.requestFrom(VL53L0X_I2C_SLAVE_ADDRESS, (int)(2 * sizeof(Lidar_RightCenter)));

readResult = I2C_readAnything(Lidar_RightCenter);

if (readResult > 0)

{

I2C_readAnything(Lidar_LeftCenter);

}

//DEBUG!!

//mySerial.printf("VL53L0X_CENTERS_ONLY case: Got LC/RC = %d, %d\n", Lidar_LeftCenter, Lidar_RightCenter);

//DEBUG!!

break;

case VL53L0X_RIGHT:

//four data values needed here

data_size = 3 * sizeof(int) + sizeof(float);

//DEBUG!!

//mySerial.printf("data_size = %d\n", data_size);

//DEBUG!!

Wire.requestFrom(VL53L0X_I2C_SLAVE_ADDRESS, data_size);

readResult = I2C_readAnything(Lidar_RightFront);

if (readResult > 0)

{

readResult = I2C_readAnything(Lidar_RightCenter);

}

if (readResult > 0)

{

readResult = I2C_readAnything(Lidar_RightRear);

}

if (readResult > 0)

{

readResult = I2C_readAnything(RightSteeringVal);

}

//DEBUG!!

//mySerial.printf("VL53L0X_RIGHT case: Got L/C/R/S = %d, %d, %d, %3.2f\n",

// Lidar_RightFront, Lidar_RightCenter, Lidar_RightRear, ToFSteeringVal);

//DEBUG!!

break;

case VL53L0X_LEFT:

//four data values needed here

data_size = 3 * sizeof(int) + sizeof(float);

Wire.requestFrom(VL53L0X_I2C_SLAVE_ADDRESS, data_size);

readResult = I2C_readAnything(Lidar_LeftFront);

if (readResult > 0)

{

readResult = I2C_readAnything(Lidar_LeftCenter);

}

if (readResult > 0)

{

readResult = I2C_readAnything(Lidar_LeftRear);

}

if (readResult > 0)

{

readResult = I2C_readAnything(LeftSteeringVal);

}

//DEBUG!!

//mySerial.printf("VL53L0X_RIGHT case: Got L/C/R/S = %d, %d, %d, %3.2f\n",

// Lidar_LeftFront, Lidar_LeftCenter, Lidar_LeftRear, ToFSteeringVal);

//DEBUG!!

break;

case VL53L0X_ALL: //added 08/05/20, chg to VL53L0X_ALL 10/31/20

//nine data values needed here - 7 ints and 2 floats

data_size = 7 * sizeof(int) + 2 * sizeof(float); //10/31/20 added rear distance

//mySerial.printf("In VL53L0X_ALL case with data_size = %d\n", data_size);

Wire.requestFrom(VL53L0X_I2C_SLAVE_ADDRESS, data_size);

//Lidar_LeftFront

readResult = I2C_readAnything(Lidar_LeftFront);

if (readResult != sizeof(Lidar_LeftFront))

{

mySerial.printf("Error reading Lidar_LeftFront\n");

}

//Lidar_LeftCenter

readResult = I2C_readAnything(Lidar_LeftCenter);

if (readResult != sizeof(Lidar_LeftCenter))

{

mySerial.printf("Error reading Lidar_LeftCenter\n");

}

//Lidar_LeftRear

readResult = I2C_readAnything(Lidar_LeftRear);

if (readResult != sizeof(Lidar_LeftRear))

{

mySerial.printf("Error reading Lidar_LeftRear\n");

}

//LeftSteeringVal

readResult = I2C_readAnything(LeftSteeringVal);

if (readResult != sizeof(LeftSteeringVal))

{

mySerial.printf("Error reading LeftSteeringVal\n");

}

//Lidar_RightFront

readResult = I2C_readAnything(Lidar_RightFront);

if (readResult != sizeof(Lidar_RightFront))

{

mySerial.printf("Error reading Lidar_RightFront\n");

}

//Lidar_RightCenter

readResult = I2C_readAnything(Lidar_RightCenter);

if (readResult != sizeof(Lidar_RightCenter))

{

mySerial.printf("Error reading Lidar_RightCenter\n");

}

//Lidar_RightRear

readResult = I2C_readAnything(Lidar_RightRear);

if (readResult != sizeof(Lidar_RightRear))

{

mySerial.printf("Error reading Lidar_RightRear\n");

}

//RightSteeringVal

readResult = I2C_readAnything(RightSteeringVal);

if (readResult != sizeof(RightSteeringVal))

{

mySerial.printf("Error reading LeftSteeringVal\n");

}

//Lidar_Rear

readResult = I2C_readAnything(Lidar_Rear);

if (readResult != sizeof(Lidar_Rear))

{

mySerial.printf("Error reading Lidar_Rear\n");

}

//mySerial.printf("%lu: VL53l0x - %d, %d, %d, %d, %d, %d, %d\n",

// millis(),

// Lidar_LeftFront, Lidar_LeftCenter, Lidar_LeftRear,

// Lidar_RightFront, Lidar_RightCenter, Lidar_RightRear,

// Lidar_Rear);

break; //10/31/20 bugfix

case VL53L0X_REAR_ONLY:

//just ONE data value needed here

data_size = sizeof(int);

Wire.requestFrom(VL53L0X_I2C_SLAVE_ADDRESS, (int)(sizeof(Lidar_Rear)));

readResult = I2C_readAnything(Lidar_Rear);

//DEBUG!!

//mySerial.printf("VL53L0X_REAR_ONLY case: Got Rear = %d\n", Lidar_Rear);

//DEBUG!!

break;

default:

break;

}

return readResult > 0; //this is true only if all reads succeed

}

void WaitForVL53L0XTeensy()

{

bVL53L0X_TeensyReady = false;

while (!bVL53L0X_TeensyReady)

{

GetRequestedVL53l0xValues(VL53L0X_READYCHECK); //this updates bVL53L0X_TeensyReady

//mySerial.printf("%lu: got %d from VL53L0X Teensy\n", millis(), bVL53L0X_TeensyReady);

delay(100);

}

Serial.print(F("Teensy setup() finished at ")); Serial.printf("%lu mSec\n", millis());

//now try to get a VL53L0X measurement

//11/08/20 rev to loop until all distance sensors provide valid data

//mySerial.printf("Msec\tLFront\tLCtr\tLRear\tRFront\tRCtr\tRRear\tRear\n");

//mySerial.printf("%lu: %d\t%d\t%d\t%d\t%d\t%d\t%d\n",

// millis(), Lidar_LeftFront, Lidar_LeftCenter, Lidar_LeftRear,

// Lidar_RightFront, Lidar_RightCenter, Lidar_RightRear, Lidar_Rear);

while (Lidar_LeftFront <= 0 || Lidar_LeftCenter <= 0 || Lidar_LeftRear <= 0

|| Lidar_LeftFront <= 0 || Lidar_LeftCenter <= 0 || Lidar_LeftRear <= 0

|| Lidar_Rear <= 0)

{

////values updated 10 times/sec in ISR

mySerial.printf("%lu: %d\t%d\t%d\t%d\t%d\t%d\t%d\n",

millis(), Lidar_LeftFront, Lidar_LeftCenter, Lidar_LeftRear,

Lidar_RightFront, Lidar_RightCenter, Lidar_RightRear, Lidar_Rear);

delay(100);

}

mySerial.printf("VL53L0X Teensy Ready at %lu\n\n", millis());

}

double GetSteeringAngle(double steerval)

{

//Purpose: Convert a steering angle into the equivalent off-parallel orientation in degrees

//Inputs:

// steerval = double value denoting current steering value

// Notes:

// 06/27/21 now steering_val/off_angle slope is a constant 0.0175

const double slopeval = 0.0175;

double offparalleldeg = steerval / slopeval; //e.g. for steerval = -0.187 @ 10cm offset, returns +21deg

//mySerial.printf("GetSteeringAngle(%d, %2.4f): slopeval = %2.4f, res %2.2f\n", ctrdist_cm, steerval, slopeval, offparalleldeg);

return offparalleldeg;

}

//11/05/15 added to get LIDAR measurement

int GetFrontDistCm()

{

//Notes:

// 12/05/15 chg to MODE line vs I2C

// 01/06/16 rev to return avg of prev distances on error

#ifndef NO_LIDAR

unsigned long pulse_width;

int LIDARdistCm;

pulse_width = pulseIn(LIDAR_MODE_PIN, HIGH); // Count how long the pulse is high in microseconds

LIDARdistCm = pulse_width / 10; // 10usec = 1 cm of distance for LIDAR-Lite

//chk for erroneous reading

if (LIDARdistCm == 0)

{

//replace with average of last three readings from aFrontDist

int avgdist = GetAvgFrontDistCm();

mySerial.printf("%lu: Error in GetFrontDistCm() - %d replaced with %d\n", millis(), LIDARdistCm, avgdist);

LIDARdistCm = avgdist;

}

//04/30/17 added limit detection/correction

LIDARdistCm = (LIDARdistCm > 0) ? LIDARdistCm : MAX_FRONT_DISTANCE_CM;

return LIDARdistCm;

#else

return 10; //safe number, I hope

#endif

}

//04/25/21 rewritten to use aFrontDist[] values

float GetAvgFrontDistCm()

{

int avgdist = 0;

for (int i = 0; i < FRONT_DIST_AVG_WINDOW_SIZE; i++)

{

//DEBUG!!

//mySerial.printf("frontdist[%d] = %d\n", FRONT_DIST_ARRAY_SIZE - 1 - i, aFrontDist[FRONT_DIST_ARRAY_SIZE - 1 - i]);

//DEBUG!!

avgdist += aFrontDist[FRONT_DIST_ARRAY_SIZE - 1 - i];

}

//DEBUG!!

//mySerial.printf("avgdisttot = %d\n", avgdist);

//DEBUG!!

avgdist = (int)((float)avgdist / (float)FRONT_DIST_AVG_WINDOW_SIZE);

//DEBUG!!

//mySerial.printf("avgdist = %d\n", avgdist);

//DEBUG!!

return avgdist;

}

//08/12/20 Extracted inline FRONT_DIST_ARRAY init code so can be called from anywhere

void InitFrontDistArray()

{