/*

Name: TwoWheelRobot.ino

Created: 6/3/2019 9:31:46 AM

Author: FRANKWIN10\Frank

Notes:

11/05/19 changed to MPU6050 DMP Version 6.12

*/

#pragma region INCLUDES

//#include <Adafruit_INA219.h>

#include <elapsedMillis.h>

#include <NewPing.h> //added 01/15/15

#include <PrintEx.h> //allows printf-style printout syntax

//#include "MPU6050_6Axis_MotionApps20.h" //06/23/18 modified for 20Hz interrupt freq

#include "MPU6050_6Axis_MotionApps_V6_12.h" //changed to this version 10/05/19

#include "I2Cdev.h" //02/19/19: this includes SBWire.h

#pragma endregion INCLUDES

StreamEx mySerial = Serial; //added 03/18/18 for printf-style printing

elapsedMillis SinceLastDistanceCheck;

elapsedMillis sinceLastTimeCheck; //used for rolling turn timeout

elapsedMillis sinceLastHdgCheck; //rolling turn heading check timer

#pragma region MOTOR_PARAMETERS

//drive wheel speed parameters

const int MOTOR_SPEED_FULL = 200; //range is 0-255

const int MOTOR_SPEED_MAX = 255; //range is 0-255

const int MOTOR_SPEED_HALF = 127; //range is 0-255

const int MOTOR_SPEED_LOW = 50; //added 01/22/15

const int MOTOR_SPEED_OFF = 0; //range is 0-255

const int MOTOR_SPEED_ADJ_FACTOR = 0; //chg to 40 at 5:55pm

const int LEFT_SPEED_COMP_VAL_FWD = 0; //left speed compensation value

const int RIGHT_SPEED_COMP_VAL_FWD = 5; //right speed compensation value

const int LEFT_SPEED_COMP_VAL_REV = 0; //left speed compensation value

const int RIGHT_SPEED_COMP_VAL_REV = 0; //right speed compensation value

//drive wheel direction constants

const boolean FWD_DIR = true;

const boolean REV_DIR = !FWD_DIR;

//Motor direction variables

boolean bLeftMotorDirIsFwd = true;

boolean bRightMotorDirIsFwd = true;

const float ROLLING_TURN_MAX_SEC_PER_DEG = 1 / 15.0; //used to limit time in rolling turns

const int OFFSIDE_MOTOR_SPEED = MOTOR_SPEED_LOW;

const int DRIVESIDE_MOTOR_SPEED_HIGH = MOTOR_SPEED_MAX;

const int DRIVESIDE_MOTOR_SPEED_LOW = MOTOR_SPEED_FULL;

const float HDG_NEAR_MATCH_VAL = 0.9; //slow the turn down here

const float HDG_FULL_MATCH_VAL = 0.99; //stop the turn here

const float HDG_MIN_MATCH_VAL = 0.6; //added 09/08/18: don't start checking slope until turn is well started

#pragma endregion Motor Parameters

#pragma region DEFINES

#define NO_MOTORS

//#define NO_LIDAR

//#define NO_PINGS

//#define NO_IRDET //added 04/05/17 for daytime in-atrium testing (too much ambient IR)

//#define DISTANCES_ONLY //added 11/14/18 to just display distances in infinite loop

#pragma endregion Program Defines

#pragma region PROGRAM_CONSTANTS

const int MIN_PING_INTERVAL_MSEC = 200;

const int CURRENT_AVERAGE_NUMBER = 10; //added 07/09/19

const int MAX_AD_VALUE = 1023;

const float ADC_REF_VOLTS = 3.3; //03/27/18 now using analogReference(EXTERNAL) with Teensy 3.3V connected to AREF

const float VOLTAGE_TO_CURRENT_RATIO = 0.75f; //Volts/Amp rev 07/09/19.

#pragma endregion Program Constants

#define LED_PIN 13 // (Arduino is 13, Teensy is 11, Teensy++ is 6)

#pragma region MOTOR_PINS

//Left Motor

int enA = 2;

int in1 = 3;

int in2 = 4;

//Right Motor

int in3 = 5;

int in4 = 6;

int enB = 7;

#pragma endregion Motor Pin Assignments

#pragma region SENSOR_PINS

const int RightSensorTrigPin = 52;

const int LeftSensorTrigPin = 53;

const int LeftSensorEchoPin = LeftSensorTrigPin;

const int RightSensorEchoPin = RightSensorTrigPin;

const int TOT_CURR_PIN = A8;

//LIDAR MODE pin (continuous mode)

const int LIDAR_MODE_PIN = 4; //mvd here 01/10/18

#pragma endregion Sensor Pin Assigns

#pragma region DIST_HDG_MEASUREMENT_SUPPORT

//misc LIDAR and Ping sensor parameters

const int MIN_OBS_DIST_CM = 20; //rev 04/28/17 for better obstacle handling

const int MAX_LR_DISTANCE_CM = 200; //04/19/15 now using sep parameters for front and side sensors

//distance and heading running average

const int LR_PING_DIST_ARRAY_SIZE = 3; //04/28/19 added to reinstate l/r dist running avg

const int LR_PING_AVG_WINDOW_SIZE = 3; //added 04/28/19 so front & lr averages can differ

const int HDG_RUNNING_AVG_ARRAY_SIZE = 20; //1 second

byte aLeftDist[LR_PING_DIST_ARRAY_SIZE];

byte aRightDist[LR_PING_DIST_ARRAY_SIZE];

#pragma endregion Distance Measurement Support

//MPU6050 mpu(0x69); //06/23/18 chg to AD0 high addr, using INT connected to Mega pin 2 (INT0)

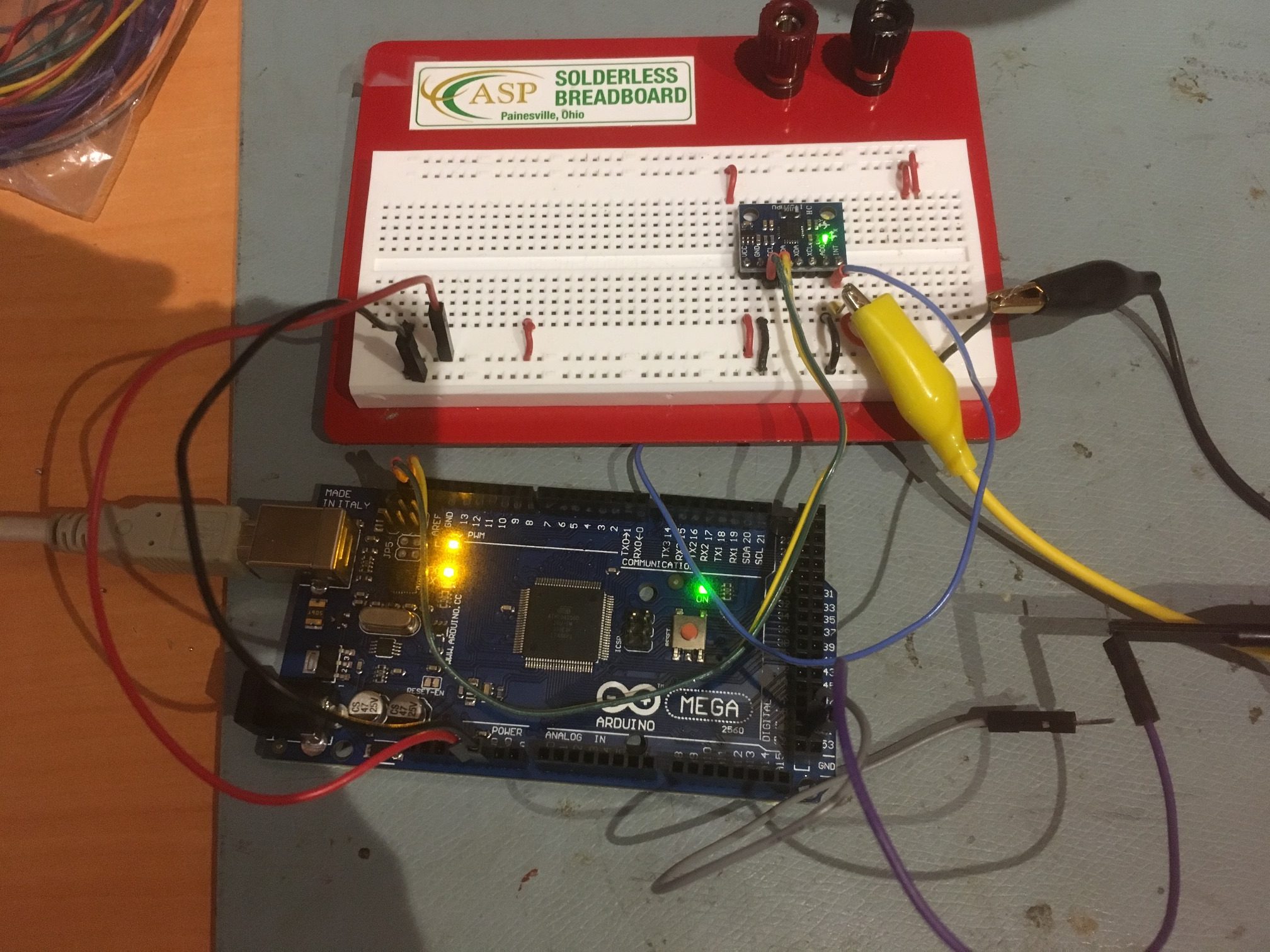

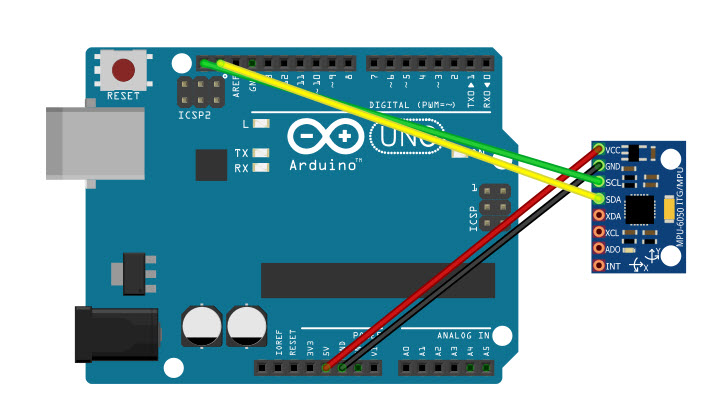

MPU6050 mpu(0x68); //07/28/19 use default addr for GY-521 on 2-motor robot

//added 01/16/15 for NewPing support

NewPing LeftPing(LeftSensorTrigPin, LeftSensorEchoPin, MAX_LR_DISTANCE_CM / 2);

NewPing RightPing(RightSensorTrigPin, RightSensorEchoPin, MAX_LR_DISTANCE_CM / 2);

#pragma region LOOP_VARS

int leftspeednum = MOTOR_SPEED_HALF;

int rightspeednum = MOTOR_SPEED_HALF;

elapsedMillis sinceLastNavUpdateMsec; //added 10/15/18 to replace lastmillisec

int m_FinalLeftSpeed = 0;

int m_FinalRightSpeed = 0;

float shuntvoltage = 0;

float busvoltage = 0;

float current_mA = 0;

float loadvoltage = 0;

float power_mW = 0;

float TotAmps = 0.f;

float SecSinceStart = 0.f;

float StartSec = 0;

int m_LeftDistCm = 0;

int m_RightDistCm = 0;

#pragma endregion Loop Variables

#pragma region MPU6050_SUPPORT

//uint8_t mpuIntStatus; // holds actual interrupt status byte from MPU c/o 10/08/19 not used for polling

uint8_t devStatus; // return status after each device operation (0 = success, !0 = error)

uint16_t DMPpacketSize; // expected DMP packet size (default is 42 bytes)

uint16_t fifoCount; // count of all bytes currently in FIFO

uint8_t fifoBuffer[64]; // FIFO storage buffer

// orientation/motion vars

Quaternion q; // [w, x, y, z] quaternion container

VectorInt16 aa; // [x, y, z] accel sensor measurements

VectorInt16 aaReal; // [x, y, z] gravity-free accel sensor measurements

VectorInt16 aaWorld; // [x, y, z] world-frame accel sensor measurements

VectorFloat gravity; // [x, y, z] gravity vector

float euler[3]; // [psi, theta, phi] Euler angle container

float ypr[3]; // [yaw, pitch, roll] yaw/pitch/roll container and gravity vector

//RTC/FRAM/MPU6050 status flags

bool RTC_Avail = true;

bool bRTCLostPower = false; //added 10/17/18

bool bFRAMReady = true;

bool bMPU6050Ready = true;

bool dmpReady = false; // set true if DMP init was successful

volatile float global_yawval = 0; //updated by GetIMUHeadingDeg()

const int MAX_FIFO_WAIT_LOOP_COUNT = 1000;

#pragma endregion MPU6050 Support

#pragma region WALL_FOLLOW_SUPPORT

#define TURNDIR_CCW false

#define TURNDIR_CW true

const int DESIRED_WALL_OFFSET_DIST_CM = 30;

const int WALL_APPR_ERR_WIN_MULTFACT = 2; //added 08/12/19

const int WALL_TRK_ERR_WIN_MULTFACT = 1; //added 08/12/19

const int VERY_FAR_AWAY_CM = 5;

const int FAR_AWAY_CM = 2;

const int CLOSE_CM = 1;

const int VERY_FAR_AWAY_TURN_DEG = 20;

const int FAR_AWAY_TURN_DEG = 10;

const int CLOSE_TURN_DEG = 5;

const int NAV_UPDATE_DELAY_MSEC = 1000;

const int TURN_INCREMENT_DEG = 10;

const int U_TURN_SEC = 8;

int m_PrevHdgCutDeg = 0;

bool m_PrevHdgCutDir = TURNDIR_CW; //CW

int m_PrevLeftDistCm = 0;

int m_PrevRightDistCm = 0;

elapsedMillis sinceLastHdgCutUpdateMsec; //added 10/15/18 to replace lastmillisec

int m_TrkErrWinMult = WALL_APPR_ERR_WIN_MULTFACT; //used to increase close in response

#pragma endregion Wall Following Support

//08/03/19 experiment with using a timer interrupt for distance checking while in a turn

const int TIMER3_OUT_PIN = 31;

void setup()

{

Serial.begin(115200);

Serial.println("Two Wheel Robot");

// join I2C bus (I2Cdev library doesn't do this automatically)

Wire.begin();

Wire.setTwiMaxLoops(15000); //08/23 needed for SBWire library

Wire.setClock(100000); //07/25/19 slow down I2C clock for better noise immunity

//motor control PWM pins

//set up left motor pins as outputs

pinMode(enA, OUTPUT);

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

//set up right motor pins as outputs

pinMode(in3, OUTPUT);

pinMode(in4, OUTPUT);

pinMode(enB, OUTPUT);

pinMode(TOT_CURR_PIN, INPUT);//07/09/19 now connected to 'Total Current' 1NA619 charge current sensor

digitalWrite(TOT_CURR_PIN, LOW); //turn off the internal pullup resistor

analogReference(EXTERNAL); //07/09/18 now using external 3.3V ref

analogRead(0); //dummy read to let the ADC circuitry settle down

// configure LED for output

pinMode(LED_PIN, OUTPUT);

// initialize MPU6050 added 09/03/18

Serial.println(F("Initializing MPU6050 ..."));

mpu.initialize();

// verify connection

Serial.println(F("Testing device connections..."));

Serial.println(mpu.testConnection() ? F("MPU6050 connection successful") : F("MPU6050 connection failed"));

Serial.println(F("Initializing DMP..."));

devStatus = mpu.dmpInitialize();

// make sure it worked (returns 0 if successful)

if (devStatus == 0)

{

// turn on the DMP, now that it's ready

Serial.println(F("Enabling DMP..."));

mpu.setDMPEnabled(true);

// set our DMP Ready flag so the main loop() function knows it's okay to use it

Serial.println(F("DMP ready! Waiting for MPU6050 drift rate to settle..."));

dmpReady = true;

// get expected DMP packet size for later comparison

DMPpacketSize = mpu.dmpGetFIFOPacketSize();

bMPU6050Ready = true;

StartSec = millis() / 1000.f;

mySerial.printf("\nMPU6050 Ready at %2.2f Sec\n", StartSec);

}

else

{

// ERROR!

// 1 = initial memory load failed

// 2 = DMP configuration updates failed

// (if it's going to break, usually the code will be 1)

Serial.print(F("DMP Initialization failed (code "));

Serial.print(devStatus);

Serial.println(F(")"));

bMPU6050Ready = false;

}

mySerial.printf("Sec\tHdg\tLdist\tRdist\tErrDeg\tPrevDeg\tTurnDir\tTurnDeg\n"); //column headers

m_LeftDistCm = GetLeftDistCm();

m_RightDistCm = GetRightDistCm();

RunBothMotors(MOTOR_SPEED_FULL, MOTOR_SPEED_FULL);

SinceLastDistanceCheck = 0;

sinceLastTimeCheck = 0; //used for rolling turn timeout

sinceLastHdgCheck = 0; //rolling turn heading check timer

mySerial.printf("Starting test turns...\n");

delay(1000);

mpu.resetFIFO(); //07/27/19 make sure we are starting with a clean slate

mpu.getIntStatus(); //required to make sure the FIFO overflow interrupt bit is reset

mySerial.printf("FIFO count = %d\n", mpu.getFIFOCount());

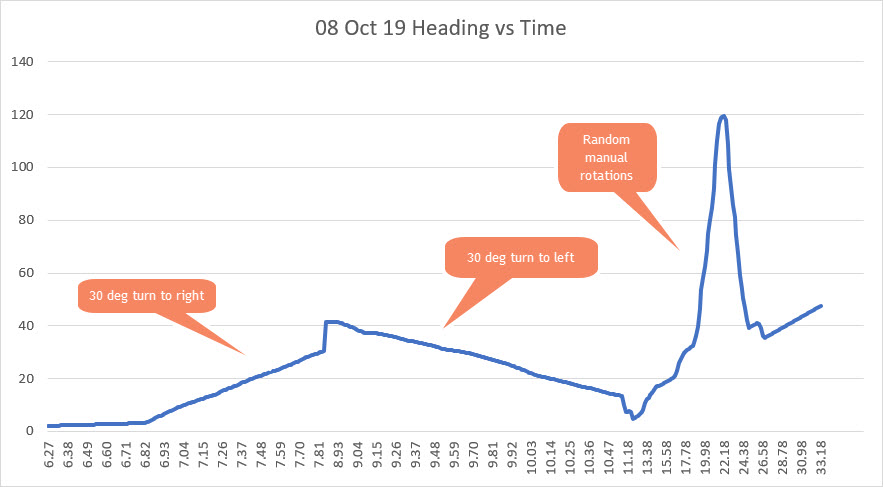

mySerial.printf("Turning right 30 deg...\n");

RollingTurn(true, true, 30);

delay(1000);

mySerial.printf("Turning left 30 deg...\n");

mySerial.printf("FIFO count = %d\n", mpu.getFIFOCount());

mpu.resetFIFO(); //07/27/19 make sure we are starting with a clean slate

mpu.getIntStatus(); //required to make sure the FIFO overflow interrupt bit is reset

mySerial.printf("FIFO count = %d\n", mpu.getFIFOCount());

RollingTurn(false, true, 30);

sinceLastNavUpdateMsec = 0;

}

void loop()

{

// if programming failed, don't try to do anything

if (dmpReady && mpu.dmpPacketAvailable())

{

//global_yawval = GetIMUHeadingDeg(); //retrieve the most current yaw value from IMU

GetIMUHeadingDeg(); //updates global_yawval if successful

// blink LED to indicate activity

bool blinkState = !blinkState;

digitalWrite(LED_PIN, blinkState);

}

//if (SecSinceStart - StartSec > U_TURN_SEC)

//{

// mySerial.printf("Turning Around!\n");

// RollingTurn(TURNDIR_CCW,true,180);

// RunBothMotorsMsec(U_TURN_SEC*1000, MOTOR_SPEED_FULL, MOTOR_SPEED_FULL);

// StopBothMotors();

// while (1);

//}

if (sinceLastNavUpdateMsec >= MIN_PING_INTERVAL_MSEC)

{

sinceLastNavUpdateMsec -= MIN_PING_INTERVAL_MSEC;

int loc_leftdist = GetLeftDistCm();

int loc_rightdist = GetRightDistCm();

int loc_disterror = 0;

int turndeg = 0;

bool turndirection = false;

UpdateDistArrays(loc_leftdist, loc_rightdist);

////decide what to do

//if (loc_leftdist < loc_rightdist)

//{

// //left wall is closer, so CCW moves twd wall, CW moves away

// loc_disterror = loc_leftdist - DESIRED_WALL_OFFSET_DIST_CM; //pos diff is 'too far away'

// turndirection = loc_disterror > 0 ? TURNDIR_CCW : TURNDIR_CW;

// if (abs(loc_disterror) > VERY_FAR_AWAY_CM) //use 20-deg cut

// {

// turndeg = VERY_FAR_AWAY_TURN_DEG;

// }

// else if (abs(loc_disterror) > FAR_AWAY_CM) //use 10-deg cut

// {

// turndeg = FAR_AWAY_TURN_DEG;

// }

// else

// {

// mySerial.printf("Close to target distance - what do I do now?\n");

// RunBothMotors(MOTOR_SPEED_FULL, MOTOR_SPEED_FULL);

// }

//}

//else //right wall is closer or equal...

//{

// //right wall is closer, so CW moves twd wall, CCW moves away

// loc_disterror = loc_rightdist - DESIRED_WALL_OFFSET_DIST_CM; //pos diff is 'too far away'

// turndirection = loc_disterror > 0 ? TURNDIR_CW : TURNDIR_CCW;

// if (abs(loc_disterror) > m_TrkErrWinMult * VERY_FAR_AWAY_CM) //use 20-deg cut

// {

// turndeg = VERY_FAR_AWAY_TURN_DEG;

// }

// else if (abs(loc_disterror) > m_TrkErrWinMult * FAR_AWAY_CM) //use 10-deg cut

// {

// turndeg = FAR_AWAY_TURN_DEG;

// }

// else if (abs(loc_disterror) > m_TrkErrWinMult * CLOSE_CM) //use 5-deg cut

// {

// turndeg = CLOSE_TURN_DEG;

// m_TrkErrWinMult = WALL_TRK_ERR_WIN_MULTFACT;

// }

// else //must be close to desired offset distance. Reduce error window size

// {

// //mySerial.printf("Close to target distance - setting turndeg to zero\n");

// turndeg = 0;

// m_TrkErrWinMult = WALL_APPR_ERR_WIN_MULTFACT; //go back to approach window sizes

// }

//}

//if (turndeg == 0)

//{

// //robot is close to target - take out any remaining cut

// //mySerial.printf("turndeg = 0; Removing Entire Cut\n");

// if (m_PrevHdgCutDeg > 0)

// {

// RollingTurn(!turndirection, true, m_PrevHdgCutDeg);

// m_PrevHdgCutDeg = 0;

// }

//}

//else if (turndeg > m_PrevHdgCutDeg)

//{

// //cut not cutting it; increase it by 10 deg

// //mySerial.printf("turndeg > m_PrevHdgCutDeg; Increasing Cut\n");

// turndeg = TURN_INCREMENT_DEG;

// RollingTurn(turndirection, true, turndeg);

// m_PrevHdgCutDeg += TURN_INCREMENT_DEG;

//}

//else if (turndeg < m_PrevHdgCutDeg)// turndeg > 0 && < m_PrevHdgCutDeg)

//{

// if (isConverging(DESIRED_WALL_OFFSET_DIST_CM, true))

// {

// //take out some of the cut

// //mySerial.printf(" turndeg > 0 && < m_PrevHdgCutDeg: Reducing Cut\n");

// turndeg = TURN_INCREMENT_DEG;

// RollingTurn(!turndirection, true, turndeg);

// m_PrevHdgCutDeg -= TURN_INCREMENT_DEG;

// }

//}

//else if (turndeg == m_PrevHdgCutDeg) //this case takes more work

//{

// if (isConverging(DESIRED_WALL_OFFSET_DIST_CM, true))

// {

// //do nothing - things are going smoothly

// }

// else

// {

// //cut has been maxed out, but dist & tgt not converging

// //increase cut in same direction as before

// //mySerial.printf("not converging - increasing cut\n");

// turndeg = TURN_INCREMENT_DEG;

// RollingTurn(turndirection, true, turndeg);

// m_PrevHdgCutDeg += TURN_INCREMENT_DEG;

// m_TrkErrWinMult = WALL_APPR_ERR_WIN_MULTFACT; //go back to approach sensitivity

// }

//}

////regardless of what happens above, continue to run the motors straight ahead

//RunBothMotors(MOTOR_SPEED_FULL, MOTOR_SPEED_FULL);

//07/09/19 if GetIMUHeadingDeg() succeeds, do the rest

TotAmps = GetTotalAmps();

SecSinceStart = millis() / 1000.f; //hopefully this will be a float result

mySerial.printf("%2.2f\t%3.2f\t%d\t%d\t%d\t%d\t%s\t%d\n",

SecSinceStart, global_yawval,loc_leftdist,loc_rightdist, loc_disterror,m_PrevHdgCutDeg, turndirection == TURNDIR_CCW ? "CCW":"CW", turndeg);

}

}

#pragma region MOTOR_SUPPORT_ROUTINES

void RunBothMotors(int leftspeednum, int rightspeednum)

{

//Purpose: Run both Motors at left/rightspeednum speeds

//Inputs:

// speednum = speed value (0 = OFF, 255 = full speed)

//Outputs: Both Motors run for timesec seconds at speednum speed

//Plan:

//Notes:

// 01/14/15 - added left/right speed offset for straightness compensation

// 01/22/15 - added code to restrict fast/slow values

// 01/24/15 - revised for continuous run - no timing

// 01/26/15 - speednum modifications moved to UpdateWallFollowmyMotorspeeds()

// 12/07/15 - chg args from &int to int

////DEBUG!!

// mySerial.printf("In RunBothMotors(%d,%d\n", leftspeednum, rightspeednum);

////DEBUG!!

SetLeftMotorSpeed(leftspeednum);

SetRightMotorSpeed(rightspeednum);

}

//12/26/14 added for independent motor speed

void RunBothMotorsMsec(int timeMsec, int leftspeednum, int rightspeednum)

{

//Purpose: Run both Motors for timesec seconds at speednum speed

//Inputs:

// timesec = time in seconds to run the Motors

// speednum = speed value (0 = OFF, 255 = full speed)

//Outputs: Both Motors run for timesec seconds at speednum speed

//Plan:

// Step 1: Apply drive to both wheels

// Step 2: Delay timsec seconds

// Step 3: Remove drive from both wheels.

//Notes:

// 01/14/15 - added left/right speed offset for straightness compensation

// 01/22/15 - added code to restrict fast/slow values

// 11/25/15 - rev to use motor driver class object

RunBothMotors(leftspeednum, rightspeednum);

//Step 2: Delay timsec seconds

delay(timeMsec);

StopBothMotors();

}

//11/25/15 added for symmetry ;-).

void StopBothMotors()

{

//added analogWrite calls to ensure speed set to zero

analogWrite(enA, MOTOR_SPEED_OFF);

analogWrite(enB, MOTOR_SPEED_OFF);

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

digitalWrite(in3, LOW);

digitalWrite(in4, LOW);

}

//01/24/15 removed time from MoveAhead sig, added MoveAheadMsec

void MoveAhead(int leftspeednum, int rightspeednum)

{

//Purpose: Move ahead continuously

//Provenance: G. Frank Paynter and Danny Frank 01/24/2014

//Inputs:

// leftspeednum = integer denoting speed (0=stop, 255 = full speed)

// rightspeednum = integer denoting speed (0=stop, 255 = full speed)

//Outputs: both drive Motors energized with the specified speed

//Plan:

// Step 1: Set forward direction for both wheels

// Step 2: Run both Motors at specified speeds

//Step 1: Set forward direction for both wheels

SetLeftMotorDir(true);

SetRightMotorDir(true);

//Step 2: Run both myMotors for timsec seconds

RunBothMotors(leftspeednum, rightspeednum);

}

void MoveReverse(int leftspeednum, int rightspeednum)

{

//Purpose: Move in reverse direction continuously - companion to MoveAhead()

//Provenance: G. Frank Paynter 09/08/18

//Inputs:

// leftspeednum = integer denoting speed (0=stop, 255 = full speed)

// rightspeednum = integer denoting speed (0=stop, 255 = full speed)

//Outputs: both drive Motors energized with the specified speed

//Plan:

// Step 1: Set reverse direction for both wheels

// Step 2: Run both Motors at specified speeds

//Step 1: Set reverse direction for both wheels

SetLeftMotorDir(false);

SetRightMotorDir(false);

//Step 2: Run both myMotors for timsec seconds

//01/24/15 - removed timing - now continuous run

RunBothMotors(leftspeednum, rightspeednum);

}

void SetLeftMotorDir(boolean bIsFwdDir)

{

if (bIsFwdDir)

{

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH);

}

else //must be REV

{

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

}

bLeftMotorDirIsFwd = bIsFwdDir;

}

void SetRightMotorDir(boolean bIsFwdDir)

{

if (bIsFwdDir)

{

digitalWrite(in3, LOW);

digitalWrite(in4, HIGH);

}

else //must be REV

{

digitalWrite(in3, HIGH);

digitalWrite(in4, LOW);

}

bRightMotorDirIsFwd = bIsFwdDir;

}

//11/25/15 added to utilize new private member variable bLeftMotorDirIsFwd

void SetLeftMotorSpeed(int speed)

{

if (bLeftMotorDirIsFwd)

{

speed = speed + LEFT_SPEED_COMP_VAL_FWD;

//check limits

speed = (speed <= MOTOR_SPEED_MAX) ? speed : MOTOR_SPEED_MAX;

speed = (speed >= MOTOR_SPEED_OFF) ? speed : MOTOR_SPEED_OFF;

}

else //must be REV

{

speed = speed + LEFT_SPEED_COMP_VAL_REV;

//check limits

speed = (speed <= MOTOR_SPEED_MAX) ? speed : MOTOR_SPEED_MAX;

speed = (speed >= MOTOR_SPEED_OFF) ? speed : MOTOR_SPEED_OFF;

}

#ifndef NO_MOTORS

//Serial.print("Left Speed = "); Serial.println(speed);

analogWrite(enA, speed);

#endif

//02/13/16 added for 'pause' debug

m_FinalLeftSpeed = speed;

}

//11/25/15 added to utilize new private member variable bRightMotorDirIsFwd

void SetRightMotorSpeed(int speed)

{

if (bRightMotorDirIsFwd)

{

speed = speed + LEFT_SPEED_COMP_VAL_FWD;

//check limits

speed = (speed <= MOTOR_SPEED_MAX) ? speed : MOTOR_SPEED_MAX;

speed = (speed >= MOTOR_SPEED_OFF) ? speed : MOTOR_SPEED_OFF;

}

else //must be REV

{

speed = speed + LEFT_SPEED_COMP_VAL_REV;

//check limits

speed = (speed <= MOTOR_SPEED_MAX) ? speed : MOTOR_SPEED_MAX;

speed = (speed >= MOTOR_SPEED_OFF) ? speed : MOTOR_SPEED_OFF;

}

//02/13/16 added for 'pause' debug

m_FinalLeftSpeed = speed;

#ifndef NO_MOTORS

//Serial.print("Right Speed = "); Serial.println(speed);

analogWrite(enB, speed);

#endif

}

#pragma endregion Motor Support Routines

bool GetIMUHeadingDeg()

{

//Purpose: Get latest yaw (heading) value from IMU

//Inputs: None. This function should only be called after mpu.dmpPacketAvailable() returns TRUE

//Outputs:

// returns true if successful, otherwise false

// global_yawval updated on success

//Plan:

//Step1: check for overflow and reset the FIFO if it occurs. In this case, wait for new packet

//Step2: read all available packets to get to latest data

//Step3: update global_yawval with latest value

//Notes:

// 10/08/19 changed return type to boolean

// 10/08/19 no longer need mpuIntStatus

//mpuIntStatus = mpu.getIntStatus(); //this resets the FIFO overflow interrupt bit

fifoCount = mpu.getFIFOCount();// get current FIFO count

// check for overflow (this should never happen unless our code is too inefficient)

//if ((mpuIntStatus & _BV(MPU6050_INTERRUPT_FIFO_OFLOW_BIT)) || fifoCount >= 1024)

if (fifoCount >= 1024)

{

//if the FIFO count reset so we can continue cleanly

mySerial.printf("FIFO overflow with FIFO count = %d\n", mpu.getFIFOCount());

mpu.resetFIFO();

// now have to wait for DMP data ready again

int wait_count = 0;

while (!mpu.dmpPacketAvailable() && wait_count < 1000)

{

delay(1);

wait_count++;

}

//if the wait loop timed out, punt

if (wait_count >= 1000)

{

mySerial.printf("wait loop timed out wait_count = %d",wait_count);

return false;

}

}

// read all available packets from FIFO

while (fifoCount >= DMPpacketSize) // Lets catch up to NOW, in case someone is using the dreaded delay()!

{

mpu.getFIFOBytes(fifoBuffer, DMPpacketSize);

// track FIFO count here in case there is > 1 packet available

// (this lets us immediately read more without waiting for an interrupt)

fifoCount -= DMPpacketSize;

}

// display Euler angles in degrees

mpu.dmpGetQuaternion(&q, fifoBuffer);

mpu.dmpGetGravity(&gravity, &q);

mpu.dmpGetYawPitchRoll(ypr, &q, &gravity);

//compute the yaw value

global_yawval = ypr[0] * 180 / M_PI;

return true;

}

float GetTotalAmps()

{

//Purpose: Get total current in amps

//Inputs:

// Voltage on TOT_CURR_PIN is approximately Ichg*2 Amps

// VOLTAGE_TO_CURRENT_RATIO = measured voltage to current ratio

//Outputs:

// returns total robot current (chg current plus running current)

//Notes:

// 02/28/18 chg name from GetBattChgAmps() to GetTotalAmps()

int ITotAnalogReading = GetAverageAnalogReading(TOT_CURR_PIN, CURRENT_AVERAGE_NUMBER); //range is 0-1023

float ITotVolts = ((float)ITotAnalogReading / (float)MAX_AD_VALUE)* ADC_REF_VOLTS;

float ITotAmps = ITotVolts * VOLTAGE_TO_CURRENT_RATIO;

return ITotAmps;

}

int GetAverageAnalogReading(int pin, int numavgs)

{

long totreads = 0;

for (int i = 0; i < numavgs; i++)

{

totreads += analogRead(pin);

}

return (int)((float)totreads / (float)numavgs); //truncation ok

}

//01/10/18 reverted to regular ping(). median distance function takes too long

int GetLeftDistCm()

{

//Serial.print("LeftPing\t"); Serial.println(millis());

//Notes:

// 04/30/17 added limit detection/correction

int timeUsec = LeftPing.ping();

//Serial.print("Left Ping Usec = "); Serial.println(timeUsec);

int distCm = LeftPing.convert_cm(timeUsec);

//04/30/17 added limit detection/correction

distCm = (distCm > 0) ? distCm : MAX_LR_DISTANCE_CM;

return distCm;

}

//01/10/18 reverted to regular ping(). median distance function takes too long

int GetRightDistCm()

{

//Serial.print("RightPing\t"); Serial.println(millis());

//Notes:

// 04/30/17 added limit detection/correction

int timeUsec = RightPing.ping();

//Serial.print("Right Ping Usec = "); Serial.println(timeUsec);

int distCm = RightPing.convert_cm(timeUsec);

//04/30/17 added limit detection/correction

distCm = (distCm > 0) ? distCm : MAX_LR_DISTANCE_CM;

return distCm;

}

bool RollingTurn(bool bIsCCW, bool bIsFwd, float numDeg)

{

//Purpose: Make a numDeg forwards or backwards CW turn

//Inputs:

// bIsFwd - True if turn is to be forward, false otherwise

// numDeg - angle to be swept out in the turn

// ROLLING_TURN_MAX_SEC_PER_DEG = const used to generate timeout proportional to turn deg

// global_yawval = IMU heading value updated by GetIMUHeadingDeg()

//Plan:

// Step1: Get current heading as starting point

// Step2: Compute new target value

// Step3: Set motor speeds based on fwd/backwds flag

// Step4: Run motors until target reached

//Notes:

// 08/22/18 now using MPU6050_CCW_INCREASES_YAWVAL define to compute tgt

// 08/29/18 removed MPU6050_CCW_INCREASES_YAWVAL - the MPU6050 DMP takes care of this

// 09/08/18 revised end-of-turn detection to include slope calc. Threshold alone is too fragile

// 09/11/18 revised to handle both turn directions

// 04/29/19 uncommented

// 07/31/19 rev for better initial heading capture

// 07/31/19 rev return type to bool

// 07/31/19 rev to eliminate timed loop - now runs as fast as possible

// 07/31/19 rev to not stop motors at end - now calling pgm is resp for this

// 10/06/19 rev for new IMU polling setup

float tgt_deg;

float timeout_sec;

bool bDoneTurning = false;

bool bTimedOut = false;

//DEBUG!!

mySerial.printf("In RollingTurn(%s, %s,%4.2f)\n", bIsCCW == TURNDIR_CCW? "CCW":"CW", bIsFwd == true? "FWD":"BKWD", numDeg);

//DEBUG!!

//Step1: Get current heading as starting point

//if (!GetIMUHeadingDeg())

//{

// mySerial.printf("RollingTurn(%d,%d,%d): Initial Heading Capture Failed!",

// bIsCCW, bIsFwd, numDeg);

// return false;

//}

//no need to continue if the IMU isn't available

if (!dmpReady)

{

return false;

}

//Wait for packet availability (times out after one second) ...

int wait_count = 0;

while (!mpu.dmpPacketAvailable() && wait_count < 1000)

{

delay(1);

wait_count++;

}

//if the wait loop timed out, punt

if (wait_count >= 1000)

{

return false;

}

//if we get to here, the IMU is OK and at least one packet is available

//global_yawval = GetIMUHeadingDeg();

GetIMUHeadingDeg(); //updates global_yawval if successful

//Step2: Compute new target value & timeout value

//timeout_sec = numDeg * ROLLING_TURN_MAX_SEC_PER_DEG;

timeout_sec = numDeg * ROLLING_TURN_MAX_SEC_PER_DEG * 10000;//10/06/19 make timeout irrelevant

tgt_deg = bIsCCW ? global_yawval + numDeg : global_yawval - numDeg;

//correct for -180/180 transition

if (tgt_deg < -180)

{

tgt_deg += 360;

}

//07/29/19 bugfix

if (tgt_deg > 180)

{

tgt_deg -= 360;

}

//DEBUG!!

mySerial.printf("Init hdg = %4.2f deg, Turn = %4.2f deg, tgt = %4.2f deg, timeout = %4.2f sec\n",

global_yawval, numDeg, tgt_deg, timeout_sec);

//DEBUG!!

//Step3: Start motors

SetRightMotorDir(bIsFwd);

SetLeftMotorDir(bIsFwd);

int rightspeed;

int leftspeed;

if (!bIsCCW) //2-motor robot is backwards from 4-motor one

{

rightspeed = (bIsFwd) ? DRIVESIDE_MOTOR_SPEED_HIGH : OFFSIDE_MOTOR_SPEED;

leftspeed = (bIsFwd) ? OFFSIDE_MOTOR_SPEED : DRIVESIDE_MOTOR_SPEED_HIGH;

}

else

{

rightspeed = (bIsFwd) ? OFFSIDE_MOTOR_SPEED : DRIVESIDE_MOTOR_SPEED_HIGH;

leftspeed = (bIsFwd) ? DRIVESIDE_MOTOR_SPEED_HIGH : OFFSIDE_MOTOR_SPEED;

}

SetLeftMotorSpeed(leftspeed);

SetRightMotorSpeed(rightspeed);

sinceLastTimeCheck = 0; //needed for watchdog timer

//mySerial.printf("hdg\typr\ttgt\tmatch\tslope\n");

bool bFirstPass = true; //for 'slowdown' print control

float curHdgMatchVal = 0;

//09/08/18 added to bolster end-of-turn detection

float prevHdgMatchVal = 0;

float matchSlope = 0;

//Step4: Run motors until target reached

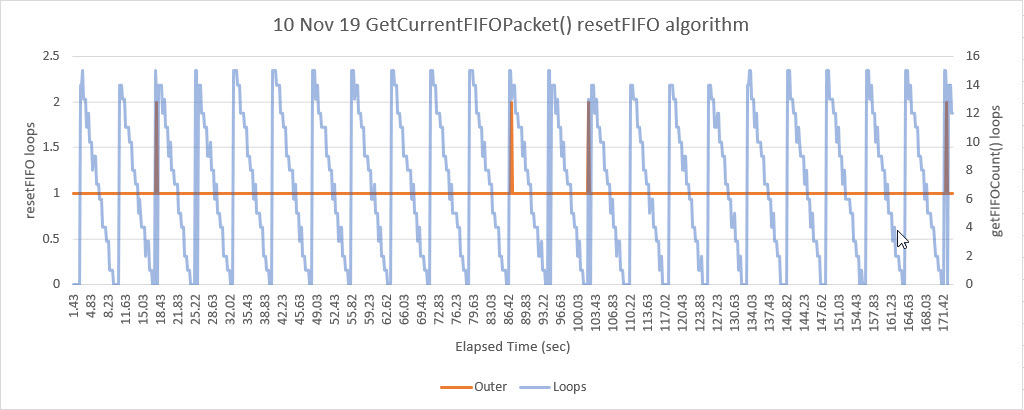

mpu.resetFIFO();

while (!bDoneTurning && !bTimedOut)

{

//GetIMUHeadingDeg(); //07/31/19 now incorporates FIFO wait loop

if (mpu.dmpPacketAvailable())

{

//global_yawval = GetIMUHeadingDeg(); //10/06/19 only do this if a new packet is avail

GetIMUHeadingDeg(); //updates global_yawval if successful

//DEBUG!!

mySerial.printf("%lu\t%4.2f\t%d\n", millis(), global_yawval, fifoCount);

//DEBUG!!

}

//07/31/19 now running as fast as we can get valid hdgs from IMU

//check for nearly there and all the way there

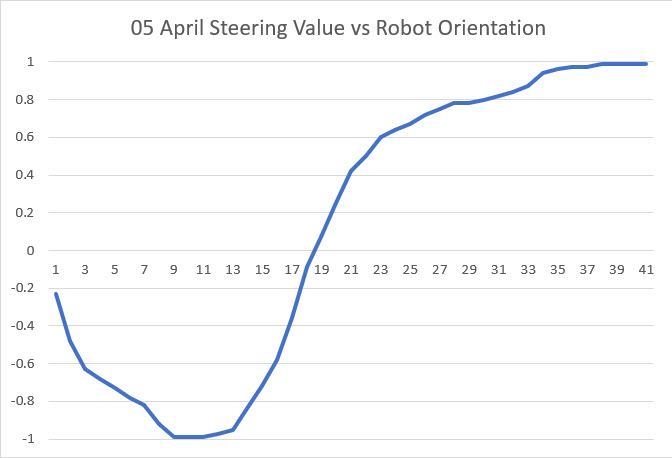

curHdgMatchVal = GetHdgMatchVal(tgt_deg, global_yawval);

matchSlope = curHdgMatchVal - prevHdgMatchVal;

if (abs(curHdgMatchVal) > HDG_NEAR_MATCH_VAL)

{

if (bFirstPass)

{

prevHdgMatchVal = curHdgMatchVal; //init baseline for slope calcs

//mySerial.printf("Slowing down at %4.2f deg\n", global_yawval);

bFirstPass = false;

}

}

//look for full match

//bDoneTurning = (curHdgMatchVal >= HDG_FULL_MATCH_VAL

// || (curHdgMatchVal >= HDG_MIN_MATCH_VAL && matchSlope < 0)); //have to use < vs <= as slope == 0 at start

bDoneTurning = (curHdgMatchVal >= HDG_FULL_MATCH_VAL

|| (curHdgMatchVal >= HDG_MIN_MATCH_VAL && matchSlope < -0.1)); //have to use < vs <= as slope == 0 at start

bTimedOut = (sinceLastTimeCheck > timeout_sec * 1000);

//DEBUG!!

if (bDoneTurning)

{

mySerial.printf("found match with yaw = %3.2f, tgt = %3.2f, match = %1.3f, and slope = %1.3f\n",

global_yawval, tgt_deg, curHdgMatchVal, matchSlope);

}

//DEBUG!!

if (bTimedOut)

{

mySerial.printf("timed out with yaw = %3.2f, tgt = %3.2f, and match = %1.3f\n", global_yawval, tgt_deg, curHdgMatchVal);

}

mpu.resetFIFO();

}

return true;

}

float GetHdgMatchVal(float tgt_deg, float cur_deg)

{

//Purpose: Compute the match ratio between two compass headings

//Inputs:

// tgt_deg = float representing target heading in +/-180 range

// global_yawval = float representing sensor yaw value in +/-180 deg range

//Outputs:

// returns result of 1 - abs(Tgt_deg - Hdg_deg)/180, all angles in 0-360 deg range

//Plan:

// Step1: convert both inputs to 0-360 deg range

// Step2: compute match ratio

//Notes:

// formula from https://gis.stackexchange.com/questions/129954/comparing-compass-bearings

//Step1: convert both inputs to 0-360 deg range

float tgthdg = (tgt_deg < 0) ? tgt_deg + 360 : tgt_deg;

float curhdg = (cur_deg < 0) ? cur_deg + 360 : cur_deg;

//Step2: compute match ratio

float match_ratio = 1 - abs(tgthdg - curhdg) / 180;

//DEBUG!!

//mySerial.printf("tgt\tcur\tmatch = %4.2f\t%4.2f\t%1.3f\n", tgthdg, curhdg, match_ratio);

//DEBUG!!

return abs(match_ratio);

}

bool isConverging(int tgtdist, bool bIsRightSide)

{

//Purpose: Determine if act dist & tgt dist are converging

//Inputs:

// tgtdist = it representing target distance

// bIsRightSide = boolean denoting side under consideration. True = right, False = left

// aRightDist[], aLeftDist[] = int arrays containing the LR_PING_DIST_ARRAY_SIZE previous ping measurements

//Plan:

// Step1: compute avg slope = (dist[LR_PING_DIST_ARRAY_SIZE-1]-dist[0])/LR_PING_DIST_ARRAY_SIZE

// Step2: if slope > 0 && dist[LR_PING_DIST_ARRAY_SIZE-1] < tgtdist, return TRUE (convergent)

// if slope < 0 && dist[LR_PING_DIST_ARRAY_SIZE-1] > tgtdist, return TRUE (convergent)

// else, return FALSE (non-convergent)

//Step1: compute avg slope = (dist[LR_PING_DIST_ARRAY_SIZE-1]-dist[0])/LR_PING_DIST_ARRAY_SIZE

int slope = 0;

int last_dist = 0;

int first_dist = 0;

if (bIsRightSide)

{

first_dist = aRightDist[0];

last_dist = aRightDist[LR_PING_DIST_ARRAY_SIZE - 1];

slope = last_dist - first_dist; //don't need to divide

}

else

{

first_dist = aLeftDist[0];

last_dist = aLeftDist[LR_PING_DIST_ARRAY_SIZE - 1];

slope = last_dist - first_dist; //don't need to divide

}

////DEBUG!!

// mySerial.printf("IsConverging: firstd/lastd = %d/%d, slope = %d\ttgtdist = %d\n", first_dist,last_dist, slope, tgtdist);

////DEBUG!!

//Step2: if slope > 0 && dist[LR_PING_DIST_ARRAY_SIZE-1] < tgtdist, return TRUE (convergent)

// if slope < 0 && dist[LR_PING_DIST_ARRAY_SIZE-1] > tgtdist, return TRUE (convergent)

// else, return FALSE (non-convergent)

if (slope > 0 && last_dist <= tgtdist) return true;

if (slope < 0 && last_dist >= tgtdist) return true;

else return false;

}

void UpdateDistArrays(int leftdist, int rightdist)

{

for (size_t i = 0; i < LR_PING_DIST_ARRAY_SIZE-1; i++)

{

aLeftDist[i] = aLeftDist[i + 1];

aRightDist[i] = aRightDist[i + 1];

}

aLeftDist[LR_PING_DIST_ARRAY_SIZE - 1] = leftdist;

aRightDist[LR_PING_DIST_ARRAY_SIZE - 1] = rightdist;

}