12087: Top of loop() - calling UpdateAllEnvironmentParameters()

Battery Voltage = 8.26

IRHomingValTotalAvg = 62

12105: glLeftCenterCm = -2097152000 glRightCenterCm = 0

glLeftCenterCm <= glRightCenterCm --> Calling TrackLeftWallOffset()

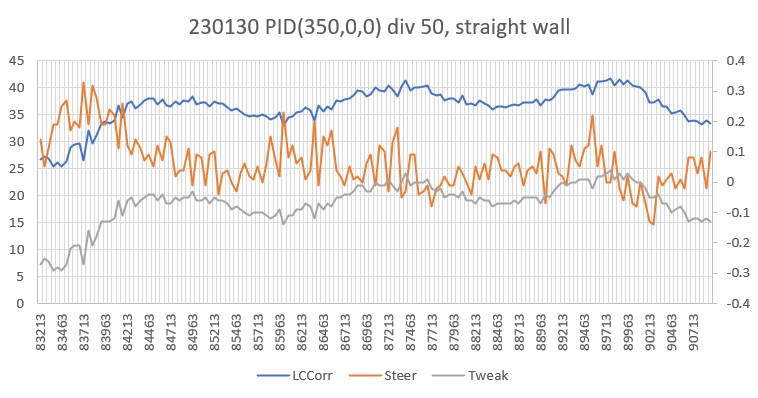

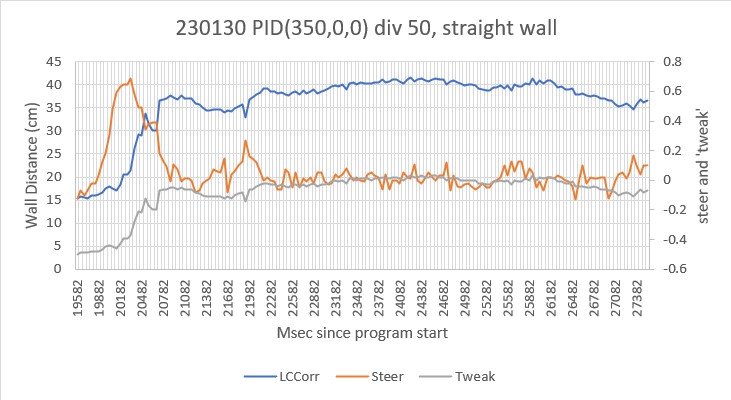

TrackLeftWallOffset: Start tracking offset of 40cm with Kp/Ki/Kd = 350.00 0.00 0.00

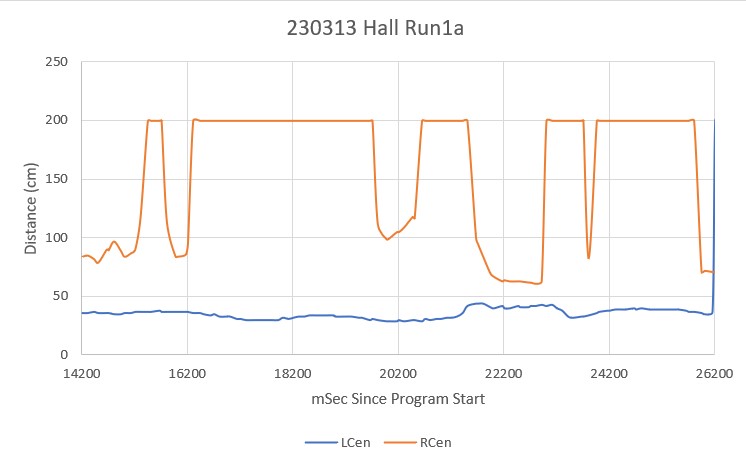

Msec LF LC LR RF RC RR F Fvar R Rvar Steer Set Output LSpd RSpd IRAvg

WallE3_Complete_V1.ino: In TrackLeftWallOffset: before while with errcode = NO_ANOMALIES

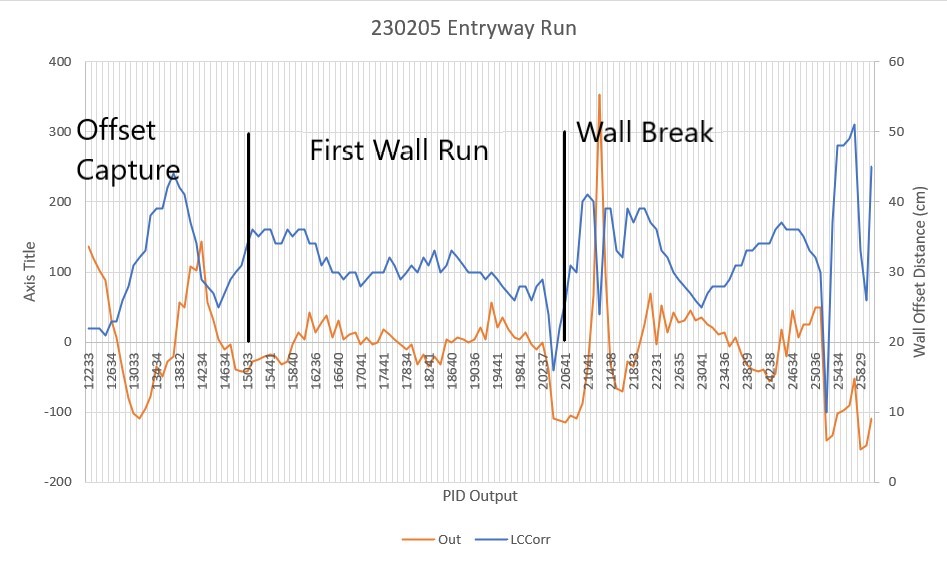

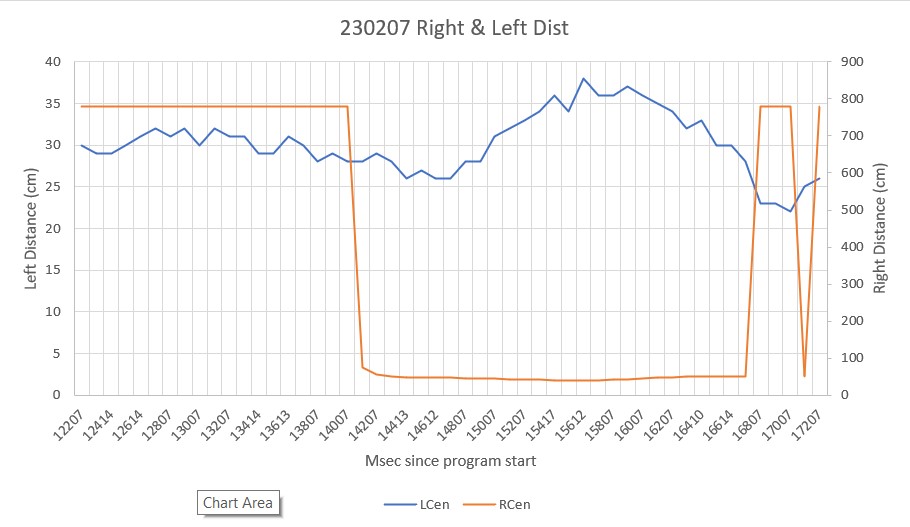

Msec LF LC LR LCCorr Steer Tweak OffCm Err LastI LastD Out Lspd Rspd

12233 24.00 22.00 24.00 22.00 -0.03 -0.36 0.00 0.39 0.00 0.39 136.50 127 0

12333 24.00 22.00 24.00 22.00 0.02 -0.36 0.00 0.34 0.00 -0.05 119.00 127 0

12440 24.00 22.00 23.00 22.00 0.07 -0.36 0.00 0.29 0.00 -0.05 101.50 127 0

12533 24.00 22.00 23.00 21.00 0.13 -0.38 0.00 0.25 0.00 -0.04 87.50 127 0

12634 26.00 25.00 24.00 23.00 0.25 -0.34 0.00 0.09 0.00 -0.16 31.50 106 43

12732 28.00 27.00 25.00 23.00 0.32 -0.34 0.00 0.02 0.00 -0.07 7.00 82 68

12835 34.00 33.00 30.00 26.00 0.39 -0.28 0.00 -0.11 0.00 -0.13 -38.50 36 113

12932 39.00 39.00 35.00 28.00 0.47 -0.24 0.00 -0.23 0.00 -0.12 -80.50 0 127

13033 42.00 43.00 37.00 31.00 0.47 -0.18 0.00 -0.29 0.00 -0.06 -101.50 0 127

13136 43.00 44.00 38.00 32.00 0.47 -0.16 0.00 -0.31 0.00 -0.02 -108.50 0 127

13237 43.00 43.00 38.00 33.00 0.41 -0.14 0.00 -0.27 0.00 0.04 -94.50 0 127

13336 41.00 42.00 38.00 38.00 0.26 -0.04 0.00 -0.22 0.00 0.05 -77.00 0 127

13434 40.00 40.00 39.00 39.00 0.12 -0.02 0.00 -0.10 0.00 0.12 -35.00 40 110

13534 39.00 41.00 38.00 39.00 0.16 -0.02 0.00 -0.14 0.00 -0.04 -49.00 26 124

13633 41.00 42.00 41.00 42.00 0.04 0.04 0.00 -0.08 0.00 0.06 -28.00 47 103

13730 42.00 44.00 43.00 44.00 -0.02 0.08 0.00 -0.06 0.00 0.02 -21.00 54 96

13832 42.00 45.00 44.00 42.00 -0.20 0.04 0.00 0.16 0.00 0.22 56.00 127 19

13934 41.00 43.00 42.00 41.00 -0.16 0.02 0.00 0.14 0.00 -0.02 49.00 124 26

14029 38.00 41.00 41.00 37.00 -0.25 -0.06 0.00 0.31 0.00 0.17 108.50 127 0

14134 34.00 36.00 36.00 34.00 -0.17 -0.12 0.00 0.29 0.00 -0.02 101.50 127 0

14234 31.00 31.00 33.00 29.00 -0.19 -0.22 0.00 0.41 0.00 0.12 143.50 127 0

14341 30.00 28.00 29.00 28.00 0.08 -0.24 0.00 0.16 0.00 -0.25 56.00 127 19

14438 30.00 28.00 28.00 27.00 0.17 -0.26 0.00 0.09 0.00 -0.07 31.50 106 43

14533 30.00 29.00 27.00 25.00 0.29 -0.30 0.00 0.01 0.00 -0.08 3.50 78 71

14634 32.00 31.00 29.00 27.00 0.29 -0.26 0.00 -0.03 0.00 -0.04 -10.50 64 85

14733 33.00 32.00 30.00 29.00 0.23 -0.22 0.00 -0.01 0.00 0.02 -3.50 71 78

14837 34.00 35.00 32.00 30.00 0.31 -0.20 0.00 -0.11 0.00 -0.10 -38.50 36 113

14934 35.00 36.00 32.00 31.00 0.30 -0.18 0.00 -0.12 0.00 -0.01 -42.00 33 117

15033 36.00 37.00 34.00 34.00 0.24 -0.12 0.00 -0.12 0.00 0.00 -42.00 33 117

15134 36.00 37.00 35.00 36.00 0.16 -0.08 0.00 -0.08 0.00 0.04 -28.00 47 103

15236 37.00 37.00 35.00 35.00 0.17 -0.10 0.00 -0.07 0.00 0.01 -24.50 50 99

15335 36.00 37.00 35.00 36.00 0.14 -0.08 0.00 -0.06 0.00 0.01 -21.00 54 96

15441 37.00 37.00 35.00 36.00 0.13 -0.08 0.00 -0.05 0.00 0.01 -17.50 57 92

15541 37.00 36.00 35.00 34.00 0.18 -0.12 0.00 -0.06 0.00 -0.01 -21.00 53 96

15641 37.00 37.00 35.00 34.00 0.21 -0.12 0.00 -0.09 0.00 -0.03 -31.50 43 106

15738 37.00 37.00 35.00 36.00 0.16 -0.08 0.00 -0.08 0.00 0.01 -28.00 47 103

15840 36.00 36.00 35.00 35.00 0.11 -0.10 0.00 -0.01 0.00 0.07 -3.50 71 78

15934 36.00 36.00 36.00 36.00 0.04 -0.08 0.00 0.04 0.00 0.05 14.00 89 61

16041 35.00 36.00 34.00 36.00 0.07 -0.08 0.00 0.01 0.00 -0.03 3.50 78 71

16137 34.00 34.00 34.00 34.00 0.00 -0.12 0.00 0.12 0.00 0.11 42.00 117 33

16236 34.00 34.00 33.00 34.00 0.08 -0.12 0.00 0.04 0.00 -0.08 14.00 89 61

16338 33.00 32.00 32.00 31.00 0.10 -0.18 0.00 0.08 0.00 0.04 28.00 103 47

16441 32.00 32.00 32.00 32.00 0.05 -0.16 0.00 0.11 0.00 0.03 38.50 113 36

16538 32.00 32.00 30.00 30.00 0.18 -0.20 0.00 0.02 0.00 -0.09 7.00 82 68

16640 31.00 31.00 30.00 30.00 0.11 -0.20 0.00 0.09 0.00 0.07 31.50 106 43

16741 32.00 31.00 29.00 29.00 0.21 -0.22 0.00 0.01 0.00 -0.08 3.50 78 71

16841 31.00 31.00 30.00 30.00 0.17 -0.20 0.00 0.03 0.00 0.02 10.50 85 64

16941 31.00 31.00 30.00 30.00 0.16 -0.20 0.00 0.04 0.00 0.01 14.00 89 61

17041 32.00 31.00 29.00 28.00 0.25 -0.24 0.00 -0.01 0.00 -0.05 -3.50 71 78

17140 31.00 31.00 29.00 29.00 0.20 -0.22 0.00 0.02 0.00 0.03 7.00 82 68

17241 32.00 32.00 30.00 30.00 0.21 -0.20 0.00 -0.01 0.00 -0.03 -3.50 71 78

17340 32.00 32.00 30.00 30.00 0.20 -0.20 0.00 0.00 0.00 0.01 0.00 75 75

17441 31.00 31.00 30.00 30.00 0.15 -0.20 0.00 0.05 0.00 0.05 17.50 92 57

17541 32.00 33.00 30.00 32.00 0.13 -0.16 0.00 0.03 0.00 -0.02 10.50 85 64

17631 32.00 32.00 31.00 31.00 0.17 -0.18 0.00 0.01 0.00 -0.02 3.50 78 71

17736 33.00 32.00 30.00 29.00 0.23 -0.22 0.00 -0.01 0.00 -0.02 -3.50 71 78

17834 33.00 33.00 31.00 30.00 0.23 -0.20 0.00 -0.03 0.00 -0.02 -10.50 64 85

17932 33.00 33.00 31.00 31.00 0.19 -0.18 0.00 -0.01 0.00 0.02 -3.50 71 78

18034 34.00 34.00 31.00 30.00 0.29 -0.20 0.00 -0.09 0.00 -0.08 -31.50 43 106

18132 33.00 34.00 31.00 32.00 0.21 -0.16 0.00 -0.05 0.00 0.04 -17.50 57 92

18241 34.00 35.00 31.00 31.00 0.28 -0.18 0.00 -0.10 0.00 -0.05 -35.00 40 110

18341 34.00 35.00 32.00 33.00 0.20 -0.14 0.00 -0.06 0.00 0.04 -21.00 54 96

18441 34.00 34.00 31.00 30.00 0.29 -0.20 0.00 -0.09 0.00 -0.03 -31.50 43 106

18541 33.00 33.00 32.00 31.00 0.17 -0.18 0.00 0.01 0.00 0.10 3.50 78 71

18640 33.00 34.00 32.00 33.00 0.14 -0.14 0.00 0.00 0.00 -0.01 0.00 75 75

18734 33.00 33.00 32.00 32.00 0.14 -0.16 0.00 0.02 0.00 0.02 7.00 82 68

18840 32.00 33.00 30.00 31.00 0.17 -0.18 0.00 0.01 0.00 -0.01 3.50 78 71

18938 32.00 32.00 30.00 30.00 0.20 -0.20 0.00 0.00 0.00 -0.01 0.00 75 75

19036 31.00 32.00 29.00 30.00 0.19 -0.20 0.00 0.01 0.00 0.01 3.50 78 71

19138 31.00 31.00 29.00 30.00 0.14 -0.20 0.00 0.06 0.00 0.05 21.00 96 54

19240 31.00 31.00 28.00 29.00 0.21 -0.22 0.00 0.01 0.00 -0.05 3.50 78 71

19341 30.00 30.00 29.00 30.00 0.04 -0.20 0.00 0.16 0.00 0.15 56.00 127 19

19441 29.00 30.00 28.00 29.00 0.16 -0.22 0.00 0.06 0.00 -0.10 21.00 96 54

19541 28.00 29.00 27.00 28.00 0.14 -0.24 0.00 0.10 0.00 0.04 35.00 110 40

19641 29.00 29.00 27.00 27.00 0.21 -0.26 0.00 0.05 0.00 -0.05 17.50 92 57

19741 29.00 29.00 26.00 26.00 0.26 -0.28 0.00 0.02 0.00 -0.03 7.00 82 68

19841 29.00 30.00 27.00 28.00 0.23 -0.24 0.00 0.01 0.00 -0.01 3.50 78 71

19941 29.00 30.00 27.00 28.00 0.20 -0.24 0.00 0.04 0.00 0.03 14.00 89 61

20041 30.00 30.00 27.00 26.00 0.29 -0.28 0.00 -0.01 0.00 -0.05 -3.50 71 78

20141 30.00 31.00 27.00 28.00 0.27 -0.24 0.00 -0.03 0.00 -0.02 -10.50 64 85

20237 30.00 31.00 28.00 29.00 0.22 -0.22 0.00 0.00 0.00 0.03 0.00 75 75

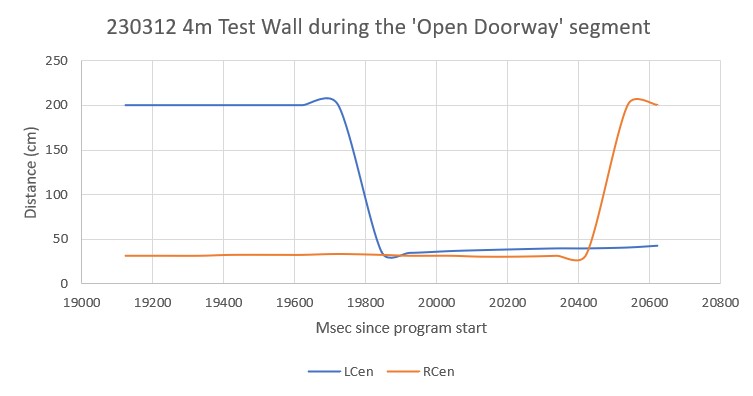

20337 33.00 32.00 29.00 24.00 0.43 -0.32 0.00 -0.11 0.00 -0.11 -38.50 36 113

20441 38.00 39.00 30.00 16.00 0.79 -0.48 0.00 -0.31 0.00 -0.20 -108.50 0 127

20541 40.00 42.00 33.00 22.00 0.68 -0.36 0.00 -0.32 0.00 -0.01 -112.00 0 127

20641 43.00 45.00 37.00 26.00 0.61 -0.28 0.00 -0.33 0.00 -0.01 -115.50 0 127

20734 43.00 44.00 38.00 31.00 0.48 -0.18 0.00 -0.30 0.00 0.03 -105.00 0 127

20832 42.00 44.00 37.00 30.00 0.51 -0.20 0.00 -0.31 0.00 -0.01 -108.50 0 127

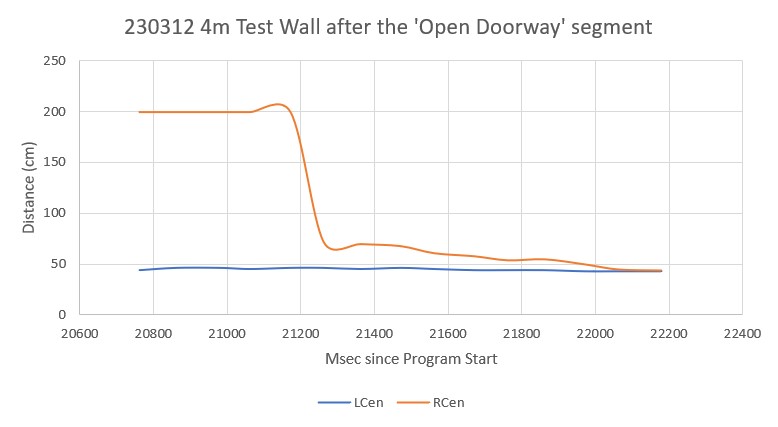

20933 40.00 44.00 37.00 40.00 0.25 0.00 0.00 -0.25 0.00 0.06 -87.50 0 127

21041 39.00 42.00 38.00 41.00 0.09 0.02 0.00 -0.11 0.00 0.14 -38.50 36 113

21140 40.00 42.00 41.00 40.00 -0.19 0.00 0.00 0.19 0.00 0.30 66.50 127 8

21233 43.00 48.00 50.00 24.00 -0.69 -0.32 0.00 1.01 0.00 0.82 353.50 127 0

21336 40.00 43.00 42.00 39.00 -0.26 -0.02 0.00 0.28 0.00 -0.73 98.00 127 0

21438 38.00 40.00 36.00 39.00 0.11 -0.02 0.00 -0.09 0.00 -0.37 -31.50 43 106

21538 38.00 39.00 35.00 33.00 0.33 -0.14 0.00 -0.19 0.00 -0.10 -66.50 8 127

21639 38.00 39.00 35.00 32.00 0.36 -0.16 0.00 -0.20 0.00 -0.01 -70.00 4 127

21740 37.00 40.00 36.00 39.00 0.10 -0.02 0.00 -0.08 0.00 0.12 -28.00 47 103

21833 38.00 39.00 36.00 37.00 0.16 -0.06 0.00 -0.10 0.00 -0.02 -35.00 40 110

21931 37.00 39.00 37.00 39.00 0.03 -0.02 0.00 -0.01 0.00 0.09 -3.50 71 78

22031 36.00 39.00 37.00 39.00 -0.05 -0.02 0.00 0.07 0.00 0.08 24.50 99 50

22133 34.00 38.00 35.00 37.00 -0.14 -0.06 0.00 0.20 0.00 0.13 70.00 127 5

22231 34.00 36.00 33.00 36.00 0.09 -0.08 0.00 -0.01 0.00 -0.21 -3.50 71 78

22335 32.00 33.00 32.00 33.00 -0.01 -0.14 0.00 0.15 0.00 0.16 52.50 127 22

22432 31.00 33.00 30.00 32.00 0.12 -0.16 0.00 0.04 0.00 -0.11 14.00 89 61

22532 29.00 30.00 28.00 30.00 0.08 -0.20 0.00 0.12 0.00 0.08 42.00 117 33

22635 29.00 30.00 28.00 29.00 0.14 -0.22 0.00 0.08 0.00 -0.04 28.00 103 47

22734 28.00 29.00 26.00 28.00 0.15 -0.24 0.00 0.09 0.00 0.01 31.50 106 43

22841 27.00 28.00 25.00 27.00 0.13 -0.26 0.00 0.13 0.00 0.04 45.50 120 29

22940 26.00 28.00 25.00 26.00 0.19 -0.28 0.00 0.09 0.00 -0.04 31.50 106 43

23041 27.00 27.00 25.00 25.00 0.20 -0.30 0.00 0.10 0.00 0.01 35.00 110 39

23141 26.00 29.00 24.00 27.00 0.19 -0.26 0.00 0.07 0.00 -0.03 24.50 99 50

23241 27.00 29.00 25.00 28.00 0.18 -0.24 0.00 0.06 0.00 -0.01 21.00 96 54

23341 28.00 30.00 26.00 28.00 0.21 -0.24 0.00 0.03 0.00 -0.03 10.50 85 64

23436 28.00 30.00 26.00 28.00 0.20 -0.24 0.00 0.04 0.00 0.01 14.00 89 61

23541 30.00 32.00 27.00 29.00 0.24 -0.22 0.00 -0.02 0.00 -0.06 -7.00 68 82

23641 31.00 32.00 29.00 31.00 0.16 -0.18 0.00 0.02 0.00 0.04 7.00 82 68

23737 32.00 34.00 30.00 31.00 0.23 -0.18 0.00 -0.05 0.00 -0.07 -17.50 57 92

23839 32.00 36.00 30.00 33.00 0.23 -0.14 0.00 -0.09 0.00 -0.04 -31.50 43 106

23935 33.00 36.00 31.00 33.00 0.25 -0.14 0.00 -0.11 0.00 -0.02 -38.50 36 113

24041 34.00 37.00 32.00 34.00 0.24 -0.12 0.00 -0.12 0.00 -0.01 -42.00 33 117

24141 34.00 37.00 32.00 34.00 0.23 -0.12 0.00 -0.11 0.00 0.01 -38.50 36 113

24238 35.00 38.00 32.00 34.00 0.28 -0.12 0.00 -0.16 0.00 -0.05 -56.00 19 127

24337 34.00 39.00 32.00 36.00 0.21 -0.08 0.00 -0.13 0.00 0.03 -45.50 29 120

24432 35.00 37.00 35.00 37.00 0.01 -0.06 0.00 0.05 0.00 0.18 17.50 92 57

24531 35.00 37.00 34.00 36.00 0.14 -0.08 0.00 -0.06 0.00 -0.11 -21.00 54 96

24634 34.00 36.00 34.00 36.00 -0.05 -0.08 0.00 0.13 0.00 0.19 45.50 120 29

24736 33.00 36.00 32.00 36.00 0.06 -0.08 0.00 0.02 0.00 -0.11 7.00 82 68

24834 31.00 35.00 31.00 35.00 0.03 -0.10 0.00 0.07 0.00 0.05 24.50 99 50

24934 31.00 33.00 30.00 33.00 0.07 -0.14 0.00 0.07 0.00 0.00 24.50 99 50

25036 29.00 32.00 28.00 32.00 0.02 -0.16 0.00 0.14 0.00 0.07 49.00 124 26

25136 28.00 30.00 27.00 30.00 0.06 -0.20 0.00 0.14 0.00 0.00 49.00 124 26

25234 41.00 41.00 29.00 10.00 1.00 -0.60 0.00 -0.40 0.00 -0.54 -140.00 0 127

25338 45.00 50.00 41.00 37.00 0.44 -0.06 0.00 -0.38 0.00 0.02 -133.00 0 127

25434 45.00 49.00 43.00 48.00 0.13 0.16 0.00 -0.29 0.00 0.09 -101.50 0 127

25535 44.00 49.00 43.00 48.00 0.12 0.16 0.00 -0.28 0.00 0.01 -98.00 0 127

25635 45.00 50.00 44.00 49.00 0.08 0.18 0.00 -0.26 0.00 0.02 -91.00 0 127

25731 48.00 51.00 49.00 51.00 -0.07 0.22 0.00 -0.15 0.00 0.11 -52.50 22 127

25829 51.00 54.00 45.00 33.00 0.58 -0.14 0.00 -0.44 0.00 -0.29 -154.00 0 127

25931 50.00 52.00 43.00 26.00 0.70 -0.28 0.00 -0.42 0.00 0.02 -147.00 0 127

26029 44.00 48.00 42.00 45.00 0.21 0.10 0.00 -0.31 0.00 0.11 -108.50 0 127

In HandleAnomalousConditions with WALL_OFFSET_DIST_AHEAD error code detected

WALL_OFFSET_DIST_AHEAD case detected with tracking case Left

In SpinTurn(CW, 90.00, 45.00) with PID = (0.7,0.3,0.0)

Init hdg = -95.99 deg, Turn = 90.00 deg, tgt = -5.99 deg, timeout = 4.00 sec

Msec Hdg PrvHdg dHdg Rate tgtDPS err Kp*err Ival Kd*Derr speed Match Slope

26094 -100.46 -95.99 -4.47 149.05 45.00 -104.05 -72.84 -31.22 -0.00 0 0.48 0.48

26124 -103.58 -100.46 -3.11 103.73 45.00 -58.73 -41.11 -48.83 0.00 0 0.46 -0.02

26154 -106.23 -103.58 -2.66 88.63 45.00 -43.63 -30.54 -61.92 0.00 0 0.44 -0.01

26184 -107.97 -106.23 -1.74 57.89 45.00 -12.89 -9.02 -65.79 0.00 0 0.43 -0.01

26214 -108.71 -107.97 -0.74 24.58 45.00 20.42 14.30 -59.66 0.00 0 0.43 -0.00

26244 -108.85 -108.71 -0.15 4.85 45.00 40.15 28.10 -47.62 0.00 0 0.43 -0.00

26274 -109.03 -108.85 -0.18 5.90 45.00 39.10 27.37 -35.89 -0.00 0 0.43 -0.00

26304 -109.03 -109.03 0.00 0.02 45.00 44.98 31.48 -22.39 0.00 9 0.43 0.00

26334 -108.99 -109.03 0.04 1.36 45.00 43.64 30.55 -9.30 -0.00 21 0.43 0.00

26364 -108.99 -108.99 0.00 0.08 45.00 44.92 31.45 4.18 0.00 35 0.43 0.00

26394 -108.84 -108.99 0.15 4.90 45.00 40.10 28.07 16.21 -0.00 44 0.43 0.00

26424 -108.54 -108.84 0.30 9.91 45.00 35.09 24.56 26.73 -0.00 51 0.43 0.00

26454 -107.46 -108.54 1.08 36.00 45.00 9.00 6.30 29.43 -0.00 35 0.44 0.01

26484 -105.94 -107.46 1.52 50.79 45.00 -5.79 -4.05 27.70 -0.00 23 0.44 0.01

26517 -104.37 -105.94 1.57 52.18 45.00 -7.18 -5.02 25.54 -0.00 20 0.45 0.01

26547 -102.98 -104.37 1.39 46.34 45.00 -1.34 -0.94 25.14 0.00 24 0.46 0.01

26577 -101.85 -102.98 1.14 37.90 45.00 7.10 4.97 27.27 0.00 32 0.47 0.01

26607 -100.90 -101.85 0.95 31.70 45.00 13.30 9.31 31.26 0.00 40 0.47 0.01

26637 -99.91 -100.90 0.98 32.72 45.00 12.28 8.59 34.94 -0.00 43 0.48 0.01

26667 -98.77 -99.91 1.14 38.01 45.00 6.99 4.90 37.04 -0.00 41 0.48 0.01

26697 -97.38 -98.77 1.39 46.40 45.00 -1.40 -0.98 36.62 -0.00 35 0.49 0.01

26727 -95.87 -97.38 1.51 50.46 45.00 -5.46 -3.82 34.98 -0.00 31 0.50 0.01

26757 -94.36 -95.87 1.51 50.41 45.00 -5.41 -3.79 33.36 0.00 29 0.51 0.01

26787 -92.85 -94.36 1.50 50.06 45.00 -5.06 -3.54 31.84 0.00 28 0.52 0.01

26817 -91.48 -92.85 1.37 45.78 45.00 -0.78 -0.55 31.61 0.00 31 0.53 0.01

26847 -90.20 -91.48 1.28 42.66 45.00 2.34 1.64 32.31 0.00 33 0.53 0.01

26877 -88.96 -90.20 1.24 41.21 45.00 3.79 2.66 33.45 0.00 36 0.54 0.01

26907 -87.73 -88.96 1.23 41.12 45.00 3.88 2.72 34.61 0.00 37 0.55 0.01

26937 -86.44 -87.73 1.29 43.13 45.00 1.87 1.31 35.17 -0.00 36 0.55 0.01

26967 -85.06 -86.44 1.38 45.97 45.00 -0.97 -0.68 34.88 -0.00 34 0.56 0.01

26997 -83.65 -85.06 1.40 46.83 45.00 -1.83 -1.28 34.33 -0.00 33 0.57 0.01

27027 -82.24 -83.65 1.41 47.14 45.00 -2.14 -1.50 33.69 -0.00 32 0.58 0.01

27057 -80.82 -82.24 1.42 47.24 45.00 -2.24 -1.57 33.02 -0.00 31 0.58 0.01

27087 -79.34 -80.82 1.48 49.31 45.00 -4.31 -3.02 31.73 -0.00 28 0.59 0.01

27117 -77.89 -79.34 1.45 48.35 45.00 -3.35 -2.35 30.73 0.00 28 0.60 0.01

27147 -76.50 -77.89 1.40 46.53 45.00 -1.53 -1.07 30.27 0.00 29 0.61 0.01

27177 -75.24 -76.50 1.25 41.74 45.00 3.26 2.28 31.24 0.00 33 0.62 0.01

27207 -74.06 -75.24 1.18 39.37 45.00 5.63 3.94 32.93 0.00 36 0.62 0.01

27237 -72.89 -74.06 1.17 38.97 45.00 6.03 4.22 34.74 0.00 38 0.63 0.01

27267 -71.64 -72.89 1.26 41.91 45.00 3.09 2.16 35.67 -0.00 37 0.64 0.01

27297 -70.21 -71.64 1.43 47.56 45.00 -2.56 -1.79 34.90 -0.00 33 0.64 0.01

27327 -68.60 -70.21 1.61 53.74 45.00 -8.74 -6.12 32.28 -0.00 26 0.65 0.01

27357 -66.99 -68.60 1.60 53.45 45.00 -8.45 -5.92 29.74 0.00 23 0.66 0.01

27387 -65.66 -66.99 1.33 44.39 45.00 0.61 0.42 29.92 0.00 30 0.67 0.01

27417 -64.52 -65.66 1.15 38.21 45.00 6.79 4.75 31.96 0.00 36 0.67 0.01

27447 -63.41 -64.52 1.11 36.90 45.00 8.10 5.67 34.39 0.00 40 0.68 0.01

27477 -62.24 -63.41 1.17 39.09 45.00 5.91 4.14 36.16 -0.00 40 0.69 0.01

27507 -60.97 -62.24 1.26 42.15 45.00 2.85 1.99 37.02 -0.00 39 0.69 0.01

27537 -59.56 -60.97 1.41 47.01 45.00 -2.01 -1.41 36.41 -0.00 35 0.70 0.01

27567 -58.01 -59.56 1.55 51.59 45.00 -6.59 -4.62 34.43 -0.00 29 0.71 0.01

27597 -56.47 -58.01 1.54 51.45 45.00 -6.45 -4.52 32.50 0.00 27 0.72 0.01

27627 -55.06 -56.47 1.41 46.98 45.00 -1.98 -1.39 31.90 0.00 30 0.73 0.01

27657 -53.70 -55.06 1.36 45.28 45.00 -0.28 -0.20 31.82 0.00 31 0.73 0.01

27687 -52.42 -53.70 1.29 42.85 45.00 2.15 1.50 32.46 0.00 33 0.74 0.01

27717 -51.17 -52.42 1.25 41.62 45.00 3.38 2.37 33.48 0.00 35 0.75 0.01

27747 -49.87 -51.17 1.30 43.25 45.00 1.75 1.23 34.00 -0.00 35 0.76 0.01

27777 -48.55 -49.87 1.32 43.91 45.00 1.09 0.76 34.33 -0.00 35 0.76 0.01

27807 -47.18 -48.55 1.37 45.83 45.00 -0.83 -0.58 34.08 -0.00 33 0.77 0.01

27837 -45.75 -47.18 1.43 47.56 45.00 -2.56 -1.79 33.31 -0.00 31 0.78 0.01

27867 -44.35 -45.75 1.40 46.76 45.00 -1.76 -1.23 32.79 0.00 31 0.79 0.01

27897 -42.98 -44.35 1.37 45.67 45.00 -0.67 -0.47 32.59 0.00 32 0.79 0.01

27927 -41.64 -42.98 1.34 44.66 45.00 0.34 0.24 32.69 0.00 32 0.80 0.01

27957 -40.38 -41.64 1.26 42.00 45.00 3.00 2.10 33.59 0.00 35 0.81 0.01

27987 -39.09 -40.38 1.29 43.00 45.00 2.00 1.40 34.19 -0.00 35 0.82 0.01

28017 -37.77 -39.09 1.32 43.87 45.00 1.13 0.79 34.52 -0.00 35 0.82 0.01

28047 -36.43 -37.77 1.34 44.76 45.00 0.24 0.17 34.60 -0.00 34 0.83 0.01

28077 -35.04 -36.43 1.38 46.14 45.00 -1.14 -0.80 34.25 -0.00 33 0.84 0.01

28107 -33.68 -35.04 1.37 45.66 45.00 -0.66 -0.46 34.05 0.00 33 0.85 0.01

28137 -32.40 -33.68 1.27 42.36 45.00 2.64 1.85 34.85 0.00 36 0.85 0.01

28167 -31.14 -32.40 1.27 42.27 45.00 2.73 1.91 35.67 0.00 37 0.86 0.01

28197 -29.83 -31.14 1.30 43.40 45.00 1.60 1.12 36.15 -0.00 37 0.87 0.01

28227 -28.38 -29.83 1.45 48.40 45.00 -3.40 -2.38 35.13 -0.00 32 0.88 0.01

28257 -26.85 -28.38 1.53 51.08 45.00 -6.08 -4.26 33.30 -0.00 29 0.88 0.01

28287 -25.38 -26.85 1.47 48.84 45.00 -3.84 -2.69 32.15 0.00 29 0.89 0.01

28317 -24.01 -25.38 1.37 45.74 45.00 -0.74 -0.52 31.93 0.00 31 0.90 0.01

28347 -22.68 -24.01 1.33 44.28 45.00 0.72 0.50 32.15 0.00 32 0.91 0.01

28377 -21.40 -22.68 1.28 42.68 45.00 2.32 1.62 32.84 0.00 34 0.91 0.01

28407 -20.12 -21.40 1.28 42.62 45.00 2.38 1.66 33.55 0.00 35 0.92 0.01

28437 -18.80 -20.12 1.32 44.10 45.00 0.90 0.63 33.82 -0.00 34 0.93 0.01

28467 -17.43 -18.80 1.37 45.64 45.00 -0.64 -0.45 33.63 -0.00 33 0.94 0.01

28497 -16.02 -17.43 1.42 47.22 45.00 -2.22 -1.55 32.96 -0.00 31 0.94 0.01

28527 -14.61 -16.02 1.40 46.83 45.00 -1.83 -1.28 32.41 0.00 31 0.95 0.01

28557 -13.23 -14.61 1.38 46.07 45.00 -1.07 -0.75 32.09 0.00 31 0.96 0.01

28587 -11.94 -13.23 1.29 42.89 45.00 2.11 1.48 32.73 0.00 34 0.97 0.01

28617 -10.72 -11.94 1.22 40.83 45.00 4.17 2.92 33.98 0.00 36 0.97 0.01

28647 -9.42 -10.72 1.29 43.09 45.00 1.91 1.34 34.55 -0.00 35 0.98 0.01

28677 -8.01 -9.42 1.41 47.03 45.00 -2.03 -1.42 33.94 -0.00 32 0.99 0.01

28707 -6.65 -8.01 1.37 45.62 45.00 -0.62 -0.43 33.76 0.00 33 1.00 0.01

average turn rate = 43.7

28710: Top of loop() - calling UpdateAllEnvironmentParameters()

Battery Voltage = 8.06

IRHomingValTotalAvg = 98

28732: glLeftCenterCm = -2080374784 glRightCenterCm = 0

glLeftCenterCm <= glRightCenterCm --> Calling TrackLeftWallOffset()

TrackLeftWallOffset: Start tracking offset of 40cm with Kp/Ki/Kd = 350.00 0.00 0.00

Msec LF LC LR RF RC RR F Fvar R Rvar Steer Set Output LSpd RSpd IRAvg

WallE3_Complete_V1.ino: In TrackLeftWallOffset: before while with errcode = NO_ANOMALIES

Msec LF LC LR LCCorr Steer Tweak OffCm Err LastI LastD Out Lspd Rspd

28859 35.00 38.00 32.00 31.00 0.36 -0.18 0.00 -0.18 0.00 -0.18 -63.00 11 127

28959 35.00 38.00 32.00 34.00 0.27 -0.12 0.00 -0.15 0.00 0.03 -52.50 22 127

29059 34.00 38.00 31.00 33.00 0.31 -0.14 0.00 -0.17 0.00 -0.02 -59.50 15 127

29159 34.00 37.00 32.00 35.00 0.19 -0.10 0.00 -0.09 0.00 0.08 -31.50 43 106

29264 33.00 36.00 32.00 35.00 0.13 -0.10 0.00 -0.03 0.00 0.06 -10.50 64 85

29367 33.00 36.00 33.00 36.00 0.06 -0.08 0.00 0.02 0.00 0.05 7.00 82 68

29467 34.00 36.00 33.00 35.00 0.13 -0.10 0.00 -0.03 0.00 -0.05 -10.50 64 85

29567 33.00 36.00 32.00 35.00 0.10 -0.10 0.00 0.00 0.00 0.03 0.00 75 75

29666 33.00 35.00 32.00 35.00 0.07 -0.10 0.00 0.03 0.00 0.03 10.50 85 64

29767 32.00 35.00 32.00 35.00 0.05 -0.10 0.00 0.05 0.00 0.02 17.50 92 57

29862 32.00 35.00 30.00 33.00 0.17 -0.14 0.00 -0.03 0.00 -0.08 -10.50 64 85

29962 31.00 34.00 30.00 34.00 0.08 -0.12 0.00 0.04 0.00 0.07 14.00 89 61

30065 25.00 29.00 29.00 21.00 -0.47 -0.38 0.00 0.85 0.00 0.81 297.50 127 0

30164 22.00 23.00 25.00 21.00 -0.26 -0.38 0.00 0.64 0.00 -0.21 224.00 127 0

30267 24.00 26.00 22.00 24.00 0.20 -0.32 0.00 0.12 0.00 -0.52 42.00 117 33

30366 26.00 27.00 24.00 26.00 0.18 -0.28 0.00 0.10 0.00 -0.02 35.00 110 40

30462 25.00 28.00 24.00 28.00 0.09 -0.24 0.00 0.15 0.00 0.05 52.50 127 22

30564 29.00 35.00 25.00 28.00 0.38 -0.24 0.00 -0.14 0.00 -0.29 -49.00 26 124

30661 749.00 824.00 705.00 207.00 1.00 3.34 0.00 -4.34 0.00 -4.20 -1519.00 0 127

30762 749.00 824.00 705.00 207.00 1.00 3.34 0.00 -4.34 0.00 0.00 -1519.00 0 127

30866 749.00 824.00 705.00 207.00 1.00 3.34 0.00 -4.34 0.00 0.00 -1519.00 0 127

30965 749.00 824.00 705.00 207.00 1.00 3.34 0.00 -4.34 0.00 0.00 -1519.00 0 127

31067 749.00 824.00 705.00 207.00 1.00 3.34 0.00 -4.34 0.00 0.00 -1519.00 0 127

31161 749.00 824.00 47.00 207.00 1.00 3.34 0.00 -4.34 0.00 0.00 -1519.00 0 127

31258 55.00 58.00 48.00 32.00 0.65 -0.16 0.00 -0.49 0.00 3.85 -171.50 0 127

31359 49.00 49.00 43.00 33.00 0.52 -0.14 0.00 -0.38 0.00 0.11 -133.00 0 127

31460 46.00 50.00 48.00 45.00 -0.26 0.10 0.00 0.16 0.00 0.54 56.00 127 19

31556 52.00 58.00 56.00 44.00 -0.43 0.08 0.00 0.35 0.00 0.19 122.50 127 0

31660 53.00 57.00 55.00 54.00 -0.19 0.28 0.00 -0.09 0.00 -0.44 -31.50 43 106

31757 46.00 50.00 48.00 46.00 -0.23 0.12 0.00 0.11 0.00 0.20 38.50 113 36

31861 43.00 47.00 44.00 46.00 -0.11 0.12 0.00 -0.01 0.00 -0.12 -3.50 71 78

31959 48.00 50.00 43.00 34.00 0.50 -0.12 0.00 -0.38 0.00 -0.37 -133.00 0 127

32056 49.00 53.00 44.00 36.00 0.50 -0.08 0.00 -0.42 0.00 -0.04 -147.00 0 127

32160 50.00 53.00 47.00 46.00 0.30 0.12 0.00 -0.42 0.00 0.00 -147.00 0 127

32259 50.00 53.00 48.00 48.00 0.25 0.16 0.00 -0.41 0.00 0.01 -143.50 0 127

32357 50.00 54.00 47.00 48.00 0.26 0.16 0.00 -0.42 0.00 -0.01 -147.00 0 127

32458 49.00 53.00 48.00 52.00 0.11 0.24 0.00 -0.35 0.00 0.07 -122.50 0 127

32558 49.00 53.00 49.00 53.00 0.02 0.26 0.00 -0.28 0.00 0.07 -98.00 0 127

32658 50.00 56.00 705.00 14.00 -1.00 -0.52 0.00 1.52 0.00 1.80 532.00 127 0

32762 749.00 824.00 705.00 207.00 1.00 3.34 0.00 -4.34 0.00 -5.86 -1519.00 0 127

32858 45.00 824.00 705.00 207.00 -1.00 3.34 0.00 -2.34 0.00 2.00 -819.00 0 127

32956 50.00 56.00 705.00 14.00 -1.00 -0.52 0.00 1.52 0.00 3.86 532.00 127 0

33061 50.00 49.00 705.00 12.00 -1.00 -0.56 0.00 1.56 0.00 0.04 546.00 127 0

33161 47.00 51.00 51.00 36.00 -0.49 -0.08 0.00 0.57 0.00 -0.99 199.50 127 0

33256 43.00 47.00 43.00 47.00 0.05 0.14 0.00 -0.19 0.00 -0.76 -66.50 8 127

33360 40.00 42.00 41.00 40.00 -0.15 0.00 0.00 0.15 0.00 0.34 52.50 127 22

33460 37.00 39.00 37.00 39.00 -0.05 -0.02 0.00 0.07 0.00 -0.08 24.50 99 50

33560 36.00 39.00 34.00 38.00 0.14 -0.04 0.00 -0.10 0.00 -0.17 -35.00 40 110

33661 35.00 38.00 32.00 34.00 0.27 -0.12 0.00 -0.15 0.00 -0.05 -52.50 22 127

33758 34.00 38.00 33.00 36.00 0.17 -0.08 0.00 -0.09 0.00 0.06 -31.50 43 106

33858 34.00 37.00 32.00 35.00 0.20 -0.10 0.00 -0.10 0.00 -0.01 -35.00 40 110

33957 33.00 36.00 33.00 36.00 0.03 -0.08 0.00 0.05 0.00 0.15 17.50 92 57

34061 32.00 35.00 32.00 35.00 0.00 -0.10 0.00 0.10 0.00 0.05 35.00 110 40

34160 31.00 34.00 30.00 34.00 0.07 -0.12 0.00 0.05 0.00 -0.05 17.50 92 57

34257 29.00 32.00 28.00 32.00 0.06 -0.16 0.00 0.10 0.00 0.05 35.00 110 40

34358 27.00 30.00 26.00 30.00 0.05 -0.20 0.00 0.15 0.00 0.05 52.50 127 22

34457 25.00 28.00 25.00 28.00 0.04 -0.24 0.00 0.20 0.00 0.05 70.00 127 5

34559 24.00 27.00 22.00 26.00 0.14 -0.28 0.00 0.14 0.00 -0.06 49.00 124 26

34661 22.00 25.00 21.00 25.00 0.11 -0.30 0.00 0.19 0.00 0.05 66.50 127 8

34760 21.00 24.00 20.00 23.00 0.16 -0.34 0.00 0.18 0.00 -0.01 63.00 127 11

34858 22.00 23.00 20.00 21.00 0.22 -0.38 0.00 0.16 0.00 -0.02 56.00 127 19

34960 38.00 41.00 26.00 10.00 1.00 -0.60 0.00 -0.40 0.00 -0.56 -140.00 0 127

35058 40.00 43.00 37.00 37.00 0.31 -0.06 0.00 -0.25 0.00 0.15 -87.50 0 127

35156 41.00 44.00 37.00 34.00 0.41 -0.12 0.00 -0.29 0.00 -0.04 -101.50 0 127

35259 42.00 44.00 39.00 40.00 0.26 0.00 0.00 -0.26 0.00 0.03 -91.00 0 127

35357 42.00 45.00 39.00 40.00 0.27 0.00 0.00 -0.27 0.00 -0.01 -94.50 0 127

35456 41.00 45.00 40.00 44.00 0.11 0.08 0.00 -0.19 0.00 0.08 -66.50 8 127

35561 42.00 46.00 42.00 46.00 -0.01 0.12 0.00 -0.11 0.00 0.08 -38.50 36 113

35660 44.00 48.00 44.00 48.00 0.01 0.16 0.00 -0.17 0.00 -0.06 -59.50 15 127

35758 48.00 51.00 44.00 42.00 0.35 0.04 0.00 -0.39 0.00 -0.22 -136.50 0 127

35857 48.00 51.00 43.00 34.00 0.52 -0.12 0.00 -0.40 0.00 -0.01 -140.00 0 127

35956 45.00 49.00 43.00 45.00 0.22 0.10 0.00 -0.32 0.00 0.08 -112.00 0 127

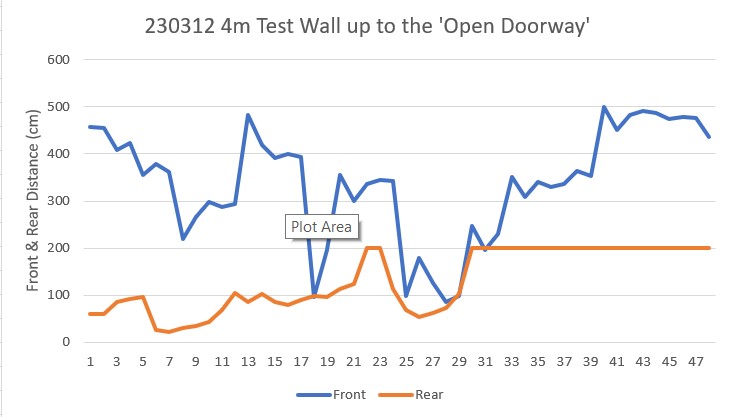

In HandleAnomalousConditions with OBSTACLE_AHEAD error code detected

OBSTACLE_AHEAD case detected with tracking case Left

In BackupAndTurn90Deg(0, 1, 200)with front distance = 32

MoveToDesiredFrontDistCm(40): Kp/Ki/Kd= 1.5/0.1/0.2

MTFD: at start, tgt = 40cm, curr_dist = 32, front/rear var = 13328.0/833.0

Msec Fdist TgtD err Ival Out Speed FVar RVar

37101 31 40 9.0 0.9 12.6 12 12802.2 762.9

37201 32 40 8.0 1.7 13.9 13 13107.7 734.6

37303 33 40 7.0 2.4 13.1 13 13773.5 707.6

37402 32 40 8.0 3.2 15.0 15 14762.2 678.3

37502 31 40 9.0 4.1 17.4 17 15945.0 640.9

37602 31 40 9.0 5.0 18.5 18 17218.5 603.2

37701 32 40 8.0 5.8 18.0 18 18431.5 571.2

37802 32 40 8.0 6.6 18.6 18 19446.0 540.0

37902 31 40 9.0 7.5 20.8 20 20131.4 503.0

37999 33 40 7.0 8.2 19.1 19 20295.0 466.7

38097 31 40 9.0 9.1 22.2 22 19799.2 436.3

38201 28 40 12.0 10.3 27.7 27 18452.5 405.8

38302 31 40 9.0 11.2 25.3 25 16007.0 372.5

38398 32 40 8.0 12.0 24.2 24 12270.2 340.6

38501 33 40 7.0 12.7 23.4 23 7011.5 312.0

38602 35 40 5.0 13.2 21.1 21 1.9 284.2

38699 39 40 1.0 13.3 15.6 15 4.2 257.3

MTFD: Stopped with front dist = 39 and errcode = WALL_OFFSET_DIST_AHEAD

In SpinTurn(CW, 90.00, 45.00) with PID = (0.7,0.3,0.0)

Init hdg = 148.51 deg, Turn = 90.00 deg, tgt = -121.49 deg, timeout = 4.00 sec

Msec Hdg PrvHdg dHdg Rate tgtDPS err Kp*err Ival Kd*Derr speed Match Slope

38758 148.50 148.51 -0.00 0.05 45.00 44.95 31.46 13.48 0.00 44 0.50 0.50

38788 148.47 148.50 -0.03 1.01 45.00 43.99 30.79 26.68 -0.00 57 0.50 -0.00

38818 148.93 148.47 0.45 15.13 45.00 29.87 20.91 35.64 -0.00 56 0.50 0.00

38848 149.93 148.93 1.00 33.37 45.00 11.63 8.14 39.13 -0.00 47 0.51 0.01

38878 151.80 149.93 1.87 62.36 45.00 -17.36 -12.15 33.92 -0.00 21 0.52 0.01

38908 153.93 151.80 2.13 71.04 45.00 -26.04 -18.23 26.11 -0.00 7 0.53 0.01

38938 155.81 153.93 1.88 62.64 45.00 -17.64 -12.35 20.82 0.00 8 0.54 0.01

38968 157.28 155.81 1.47 48.98 45.00 -3.98 -2.79 19.62 0.00 16 0.55 0.01

38998 158.27 157.28 0.99 32.85 45.00 12.15 8.50 23.27 0.00 31 0.55 0.01

39028 159.01 158.27 0.74 24.74 45.00 20.26 14.19 29.35 0.00 43 0.56 0.00

39058 159.81 159.01 0.81 26.85 45.00 18.15 12.70 34.79 -0.00 47 0.56 0.00

39088 160.92 159.81 1.11 36.94 45.00 8.06 5.64 37.21 -0.00 42 0.57 0.01

39118 162.34 160.92 1.42 47.45 45.00 -2.45 -1.72 36.47 -0.00 34 0.58 0.01

39148 163.92 162.34 1.57 52.34 45.00 -7.34 -5.14 34.27 -0.00 29 0.59 0.01

39178 165.53 163.92 1.62 53.96 45.00 -8.96 -6.27 31.58 -0.00 25 0.59 0.01

39208 167.02 165.53 1.49 49.71 45.00 -4.71 -3.29 30.17 0.00 26 0.60 0.01

39238 168.33 167.02 1.30 43.40 45.00 1.60 1.12 30.65 0.00 31 0.61 0.01

39268 169.54 168.33 1.22 40.50 45.00 4.50 3.15 32.00 0.00 35 0.62 0.01

39298 170.75 169.54 1.21 40.37 45.00 4.63 3.24 33.39 0.00 36 0.62 0.01

39328 171.95 170.75 1.20 39.97 45.00 5.03 3.52 34.90 0.00 38 0.63 0.01

39358 173.25 171.95 1.30 43.34 45.00 1.66 1.16 35.40 -0.00 36 0.64 0.01

39388 174.78 173.25 1.53 50.96 45.00 -5.96 -4.17 33.61 -0.00 29 0.65 0.01

39418 176.31 174.78 1.53 51.11 45.00 -6.11 -4.28 31.78 -0.00 27 0.65 0.01

39448 177.86 176.31 1.55 51.69 45.00 -6.69 -4.69 29.77 -0.00 25 0.66 0.01

39478 179.33 177.86 1.46 48.74 45.00 -3.74 -2.62 28.65 0.00 26 0.67 0.01

39508 -179.48 179.33 1.19 39.81 45.00 5.19 3.64 30.21 0.00 33 0.68 0.01

39538 -178.42 -179.48 1.06 35.32 45.00 9.68 6.78 33.11 0.00 39 0.68 0.01

39568 -177.27 -178.42 1.15 38.26 45.00 6.74 4.72 35.14 -0.00 39 0.69 0.01

39598 -175.90 -177.27 1.37 45.81 45.00 -0.81 -0.57 34.89 -0.00 34 0.70 0.01

39628 -174.40 -175.90 1.50 50.03 45.00 -5.03 -3.52 33.38 -0.00 29 0.71 0.01

39658 -172.88 -174.40 1.51 50.42 45.00 -5.42 -3.80 31.76 -0.00 27 0.71 0.01

39688 -171.45 -172.88 1.43 47.82 45.00 -2.82 -1.97 30.91 0.00 28 0.72 0.01

39718 -170.21 -171.45 1.24 41.42 45.00 3.58 2.51 31.98 0.00 34 0.73 0.01

39748 -169.01 -170.21 1.19 39.78 45.00 5.22 3.66 33.55 0.00 37 0.74 0.01

39778 -167.66 -169.01 1.35 44.97 45.00 0.03 0.02 33.56 -0.00 33 0.74 0.01

39808 -166.16 -167.66 1.51 50.25 45.00 -5.25 -3.68 31.98 -0.00 28 0.75 0.01

39838 -164.72 -166.16 1.44 47.87 45.00 -2.87 -2.01 31.12 0.00 29 0.76 0.01

39868 -163.15 -164.72 1.57 52.41 45.00 -7.41 -5.19 28.90 -0.00 23 0.77 0.01

39898 -161.37 -163.15 1.78 59.37 45.00 -14.37 -10.06 24.59 -0.00 14 0.78 0.01

39928 -159.85 -161.37 1.51 50.40 45.00 -5.40 -3.78 22.97 0.00 19 0.79 0.01

39958 -159.05 -159.85 0.81 26.86 45.00 18.14 12.70 28.41 0.00 41 0.79 0.00

39988 -158.52 -159.05 0.53 17.77 45.00 27.23 19.06 36.58 0.00 55 0.79 0.00

40018 -157.22 -158.52 1.29 43.09 45.00 1.91 1.34 37.15 -0.00 38 0.80 0.01

40051 -155.56 -157.22 1.66 55.34 45.00 -10.34 -7.24 34.05 -0.00 26 0.81 0.01

40081 -153.97 -155.56 1.60 53.19 45.00 -8.19 -5.73 31.59 0.00 25 0.82 0.01

40111 -152.50 -153.97 1.47 49.00 45.00 -4.00 -2.80 30.39 0.00 27 0.83 0.01

40141 -151.30 -152.50 1.20 39.86 45.00 5.14 3.60 31.94 0.00 35 0.83 0.01

40171 -150.27 -151.30 1.03 34.50 45.00 10.50 7.35 35.09 0.00 42 0.84 0.01

40201 -149.28 -150.27 0.99 32.94 45.00 12.06 8.44 38.70 0.00 47 0.85 0.01

40231 -147.96 -149.28 1.32 43.98 45.00 1.02 0.72 39.01 -0.00 39 0.85 0.01

40261 -146.50 -147.96 1.46 48.71 45.00 -3.71 -2.59 37.90 -0.00 35 0.86 0.01

40291 -145.13 -146.50 1.37 45.61 45.00 -0.61 -0.43 37.72 0.00 37 0.87 0.01

40321 -143.85 -145.13 1.28 42.65 45.00 2.35 1.64 38.42 0.00 40 0.88 0.01

40351 -142.45 -143.85 1.40 46.52 45.00 -1.52 -1.06 37.97 -0.00 36 0.88 0.01

40381 -141.00 -142.45 1.45 48.45 45.00 -3.45 -2.41 36.93 -0.00 34 0.89 0.01

40411 -139.62 -141.00 1.38 45.99 45.00 -0.99 -0.69 36.64 0.00 35 0.90 0.01

40441 -138.23 -139.62 1.39 46.38 45.00 -1.38 -0.96 36.22 -0.00 35 0.91 0.01

40471 -136.79 -138.23 1.44 47.88 45.00 -2.88 -2.02 35.36 -0.00 33 0.92 0.01

40501 -135.39 -136.79 1.40 46.74 45.00 -1.74 -1.22 34.84 0.00 33 0.92 0.01

40531 -134.24 -135.39 1.15 38.30 45.00 6.70 4.69 36.85 0.00 41 0.93 0.01

40561 -132.98 -134.24 1.26 42.06 45.00 2.94 2.06 37.73 -0.00 39 0.94 0.01

40591 -131.67 -132.98 1.31 43.69 45.00 1.31 0.91 38.12 -0.00 39 0.94 0.01

40621 -130.14 -131.67 1.53 51.09 45.00 -6.09 -4.27 36.29 -0.00 32 0.95 0.01

40651 -128.64 -130.14 1.50 49.91 45.00 -4.91 -3.44 34.82 0.00 31 0.96 0.01

40681 -127.20 -128.64 1.44 47.92 45.00 -2.92 -2.04 33.94 0.00 31 0.97 0.01

40711 -125.79 -127.20 1.41 47.09 45.00 -2.09 -1.46 33.32 0.00 31 0.98 0.01

40741 -124.45 -125.79 1.34 44.72 45.00 0.28 0.19 33.40 0.00 33 0.98 0.01

40771 -123.15 -124.45 1.29 43.15 45.00 1.85 1.29 33.96 0.00 35 0.99 0.01

average turn rate = 43.3

BackupAndTurn90Deg finished

40776: Top of loop() - calling UpdateAllEnvironmentParameters()

Battery Voltage = 8.04

IRHomingValTotalAvg = 109

40802: glLeftCenterCm = -2080374784 glRightCenterCm = 0

glLeftCenterCm <= glRightCenterCm --> Calling TrackLeftWallOffset()

TrackLeftWallOffset: Start tracking offset of 40cm with Kp/Ki/Kd = 350.00 0.00 0.00

Msec LF LC LR RF RC RR F Fvar R Rvar Steer Set Output LSpd RSpd IRAvg

WallE3_Complete_V1.ino: In TrackLeftWallOffset: before while with errcode = NO_ANOMALIES

Msec LF LC LR LCCorr Steer Tweak OffCm Err LastI LastD Out Lspd Rspd

40928 38.00 41.00 40.00 40.00 -0.13 0.00 0.00 0.13 0.00 0.13 45.50 120 29

41028 35.00 40.00 40.00 26.00 -0.54 -0.28 0.00 0.82 0.00 0.69 287.00 127 0

41128 33.00 31.00 37.00 24.00 -0.41 -0.32 0.00 0.73 0.00 -0.09 255.50 127 0

41227 38.00 37.00 29.00 15.00 0.81 -0.50 0.00 -0.31 0.00 -1.04 -108.50 0 127

41328 47.00 50.00 35.00 13.00 1.00 -0.54 0.00 -0.46 0.00 -0.15 -161.00 0 127

41428 54.00 55.00 48.00 33.00 0.59 -0.14 0.00 -0.45 0.00 0.01 -157.50 0 127

41528 53.00 55.00 49.00 42.00 0.42 0.04 0.00 -0.46 0.00 -0.01 -161.00 0 127

41627 51.00 54.00 49.00 52.00 0.16 0.24 0.00 -0.40 0.00 0.06 -140.00 0 127

41728 51.00 53.00 48.00 46.00 0.30 0.12 0.00 -0.42 0.00 -0.02 -147.00 0 127

41829 49.00 51.00 46.00 45.00 0.27 0.10 0.00 -0.37 0.00 0.05 -129.50 0 127

41926 50.00 51.00 48.00 49.00 0.15 0.18 0.00 -0.33 0.00 0.04 -115.50 0 127

42026 50.00 52.00 48.00 48.00 0.21 0.16 0.00 -0.37 0.00 -0.04 -129.50 0 127

42129 51.00 53.00 48.00 45.00 0.32 0.10 0.00 -0.42 0.00 -0.05 -147.00 0 127

42229 51.00 54.00 48.00 47.00 0.30 0.14 0.00 -0.44 0.00 -0.02 -154.00 0 127

42326 52.00 55.00 49.00 49.00 0.28 0.18 0.00 -0.46 0.00 -0.02 -161.00 0 127

42427 53.00 55.00 49.00 47.00 0.32 0.14 0.00 -0.46 0.00 0.00 -161.00 0 127

42529 51.00 54.00 49.00 51.00 0.18 0.22 0.00 -0.40 0.00 0.06 -140.00 0 127

42627 51.00 53.00 48.00 47.00 0.27 0.14 0.00 -0.41 0.00 -0.01 -143.50 0 127