/*

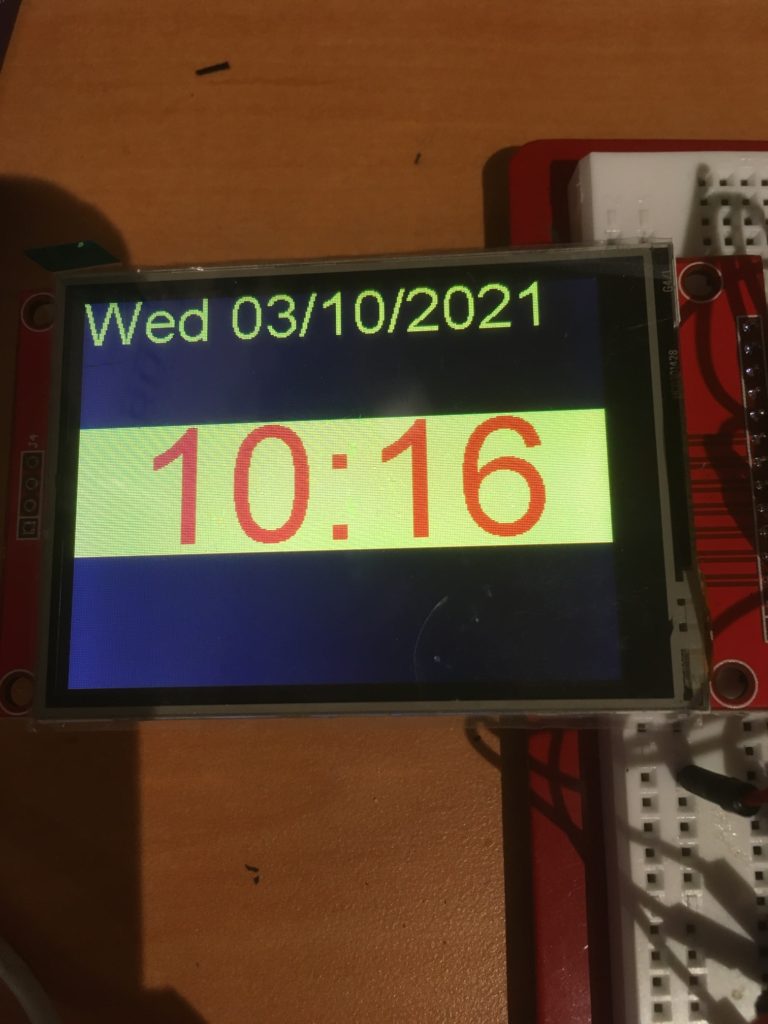

Name: Teensy_LCDClockV4.ino

Created: 3/9/2021 11:12:31 AM

Author: FRANKNEWXPS15\Frank

This project was cloned from Teensy_LCDClockV3 to re-investigate the use of proportional fonts

*/

#include <XPT2046_Touchscreen.h>

#include <ILI9341_t3n.h>

#include <Wire.h>

#include "RTClib.h"

#include "elapsedMillis.h"

#include "CustomBox.h"

#include "ili9341_t3n_font_Arial.h"

#define N0_DIAGNOSTICS

//****************************************************************************

// Settings and objects

//****************************************************************************

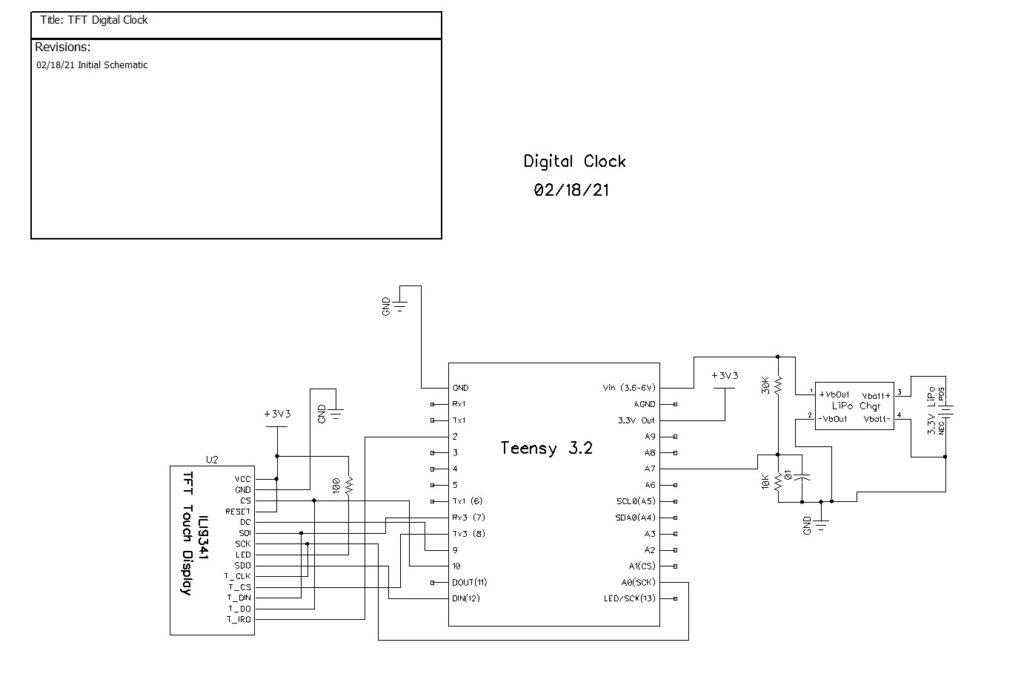

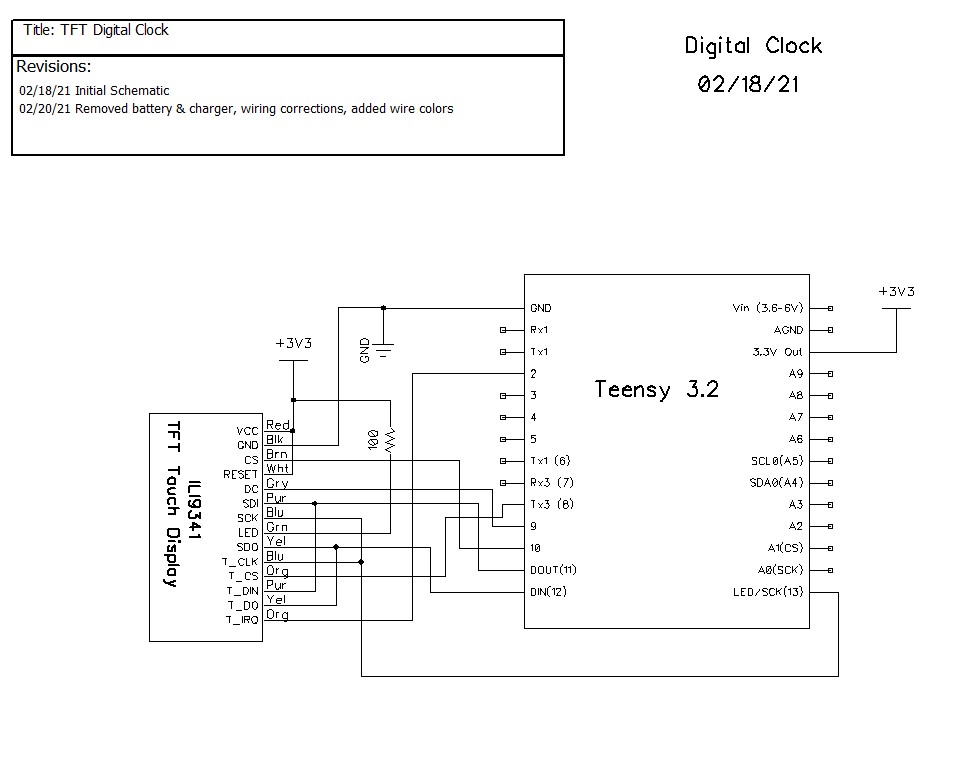

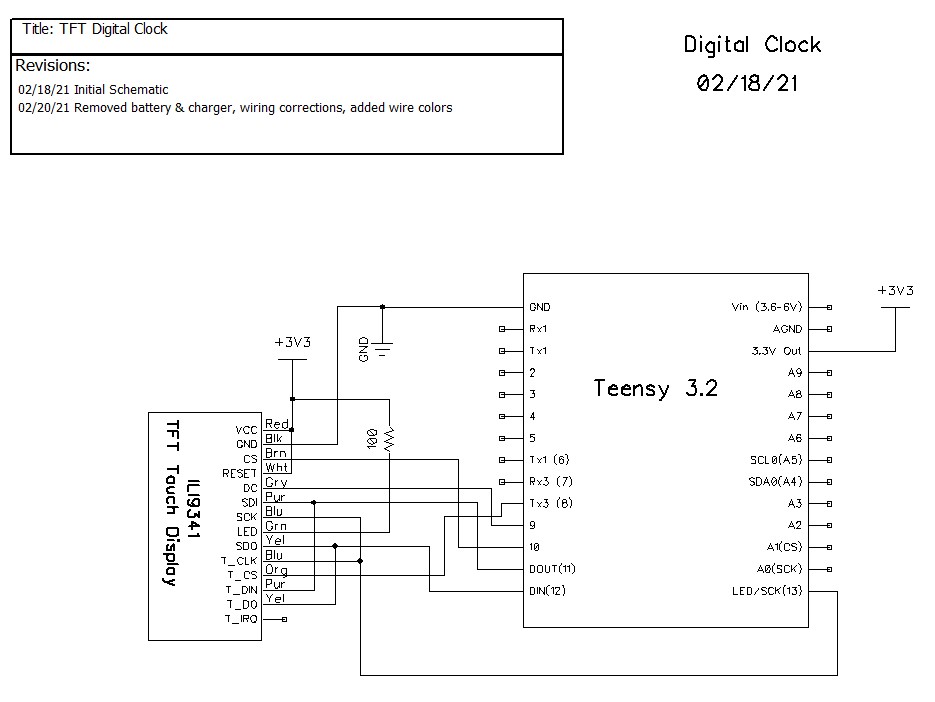

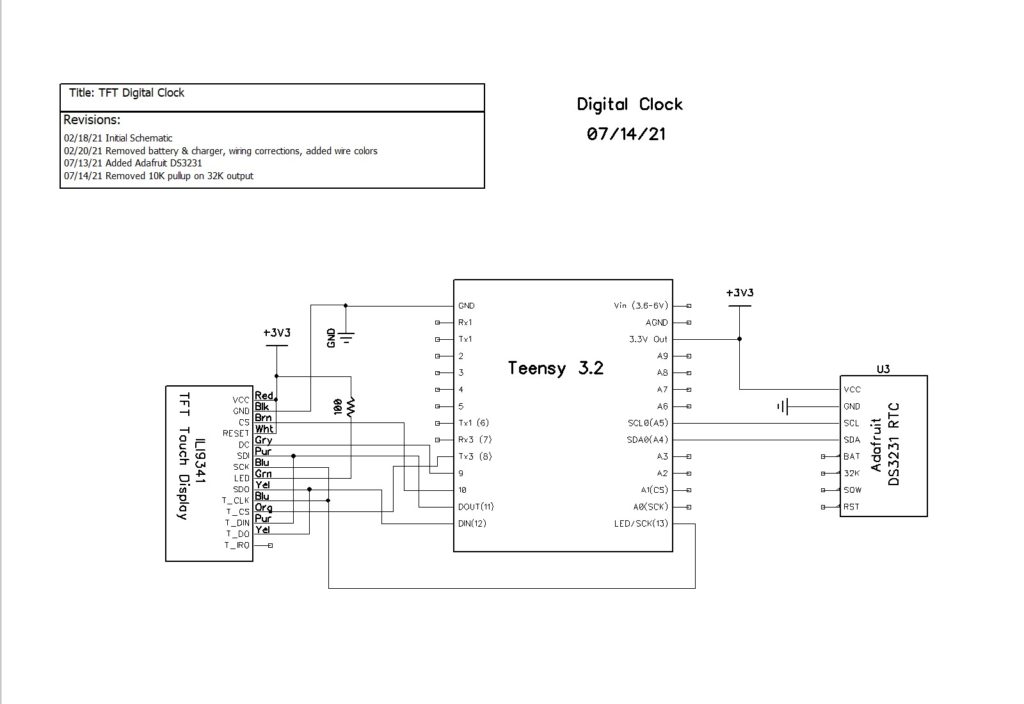

#pragma region DISPLAY_PIN_ASSIGNMENTS

//02/15/21 pin assignments from https://www.pjrc.com/store/display_ili9341_touch.html

#define TFT_DC 9

#define TFT_CS 10

#define TFT_RST 7

#define TFT_SCK 13

#define TFT_MISO 12

#define TFT_MOSI 11

#define TOUCH_CS 8

#pragma endregion DISPLAY_PIN_ASSIGNMENTS

XPT2046_Touchscreen ts(TOUCH_CS);

ILI9341_t3n tft = ILI9341_t3n(TFT_CS, TFT_DC, TFT_RST, TFT_MOSI, TFT_SCK, TFT_MISO);

elapsedMillis mSecSinceLastClockUpdate;

const int CLOCK_UPDATE_MSEC = 1000;

#pragma region DISP_AND_ADJ_BOX_PARAMETERS

// Size of the color selection boxes and the paintbrush size

#define MAX_DISPLAY_X 240

#define MAX_DISPLAY_Y 320

#define SCREEN_ORIENTATION_1

#define TS_MINX 600

#define TS_MINY 600

#define TS_MAXX 3758

#define TS_MAXY 3612

const int PLUSBOX_X = 20;

const int PLUSBOX_Y = 180;

const int PLUSBOX_WIDTH = 50;

const int PLUSBOX_HEIGHT = 50;

const int PLUSBOX_COLOR = ILI9341_BLUE;

const int MINUSBOX_X = 120;

const int MINUSBOX_Y = 180;

const int MINUSBOX_WIDTH = 50;

const int MINUSBOX_HEIGHT = 50;

const int MINUSBOX_COLOR = ILI9341_YELLOW;

const String nextstr = "NEXT";

const int nextstr_width = 70;

const int nextstr_height = 20;

const int NEXTBOX_X = 220;

const int NEXTBOX_Y = 180;

const int NEXTBOX_COLOR = ILI9341_GREEN;

const int NEXTBOX_WIDTH = 100;

const int NEXTBOX_HEIGHT = 50;

const int TIME_BOX_X = 0;

const int TIME_BOX_Y = 82;

const int TIME_BOX_WIDTH = 350;

const int TIME_BOX_HEIGHT = 80;

const int DATE_BOX_X = 0;

const int DATE_BOX_Y = 0;

const int DATE_BOX_WIDTH = 320;

const int DATE_BOX_HEIGHT = 30;

//03/05/21 used to hide adjustment boxes

const int ALL_ADJ_BOXES_WIDTH = NEXTBOX_X + NEXTBOX_WIDTH;

const int ALL_ADJ_BOXES_HEIGHT = 50;

const int TIME_HIGHLIGHT_BOX_WIDTH = 75;

const int TIME_HIGHLIGHT_BOX_HEIGHT = 5;

const int TIME_HIGHLIGHT_BOX_YLOC = 75;

const int ALL_TIME_HIGHLIGHT_BOX_WIDTH = ALL_ADJ_BOXES_WIDTH;

const int DATE_HIGHLIGHT_BOX_WIDTH = 40;

const int DATE_HIGHLIGHT_BOX_HEIGHT = 5;

const int DATE_HIGHLIGHT_BOX_YLOC = 40;

const int ALL_DATE_HIGHLIGHT_BOX_WIDTH = ALL_ADJ_BOXES_WIDTH;

CustomBox PlusBox(PLUSBOX_X, PLUSBOX_Y, PLUSBOX_WIDTH, PLUSBOX_HEIGHT, PLUSBOX_COLOR);

CustomBox MinusBox(MINUSBOX_X, MINUSBOX_Y, MINUSBOX_WIDTH, MINUSBOX_HEIGHT, MINUSBOX_COLOR);

CustomBox NextBox(NEXTBOX_X, NEXTBOX_Y, NEXTBOX_WIDTH, NEXTBOX_HEIGHT, NEXTBOX_COLOR);

CustomBox HourHighlightBox(20, TIME_HIGHLIGHT_BOX_YLOC, TIME_HIGHLIGHT_BOX_WIDTH, TIME_HIGHLIGHT_BOX_HEIGHT, ILI9341_WHITE);

CustomBox MinuteHighlightBox(120, TIME_HIGHLIGHT_BOX_YLOC, TIME_HIGHLIGHT_BOX_WIDTH, TIME_HIGHLIGHT_BOX_HEIGHT, ILI9341_WHITE);

CustomBox SecondHighlightBox(230, TIME_HIGHLIGHT_BOX_YLOC, TIME_HIGHLIGHT_BOX_WIDTH, TIME_HIGHLIGHT_BOX_HEIGHT, ILI9341_WHITE);

CustomBox MonthHighlightBox(72, DATE_HIGHLIGHT_BOX_YLOC, DATE_HIGHLIGHT_BOX_WIDTH, DATE_HIGHLIGHT_BOX_HEIGHT, ILI9341_WHITE);

CustomBox DayHighlightBox(132, DATE_HIGHLIGHT_BOX_YLOC, DATE_HIGHLIGHT_BOX_WIDTH, DATE_HIGHLIGHT_BOX_HEIGHT, ILI9341_WHITE);

CustomBox YearHighlightBox(178, DATE_HIGHLIGHT_BOX_YLOC, 90, DATE_HIGHLIGHT_BOX_HEIGHT, ILI9341_WHITE);

CustomBox TimeBox(TIME_BOX_X, TIME_BOX_Y, TIME_BOX_WIDTH, TIME_BOX_HEIGHT, ILI9341_BLACK);

CustomBox DateBox(DATE_BOX_X, DATE_BOX_Y, DATE_BOX_WIDTH, DATE_BOX_HEIGHT, ILI9341_BLACK);

enum AdjustmentState

{

ADJ_NONE = 0,

ADJ_HOUR,

ADJ_MIN,

ADJ_SEC,

ADJ_DAYOFWEEK,

ADJ_MONTH,

ADJ_DAY,

ADJ_YEAR

};

const char AdjValNameArray[8][9] = { "ADJ_NONE", "ADJ_HOUR", "ADJ_MIN", "ADJ_SEC", "ADJ_DOW", "ADJ_MNTH", "ADJ_DAY", "ADJ_YEAR" };

int aDaysInMonth[] = { 31,28,31,30,31,30,31,31,30,31,30,31 };

AdjustmentState CurAdjState = ADJ_NONE;

const int TOUCH_TIMEOUT_MSEC = 5000; //reverts to regular display if no further touch input

elapsedMillis mSecSinceLastTouch; //timer for touch timout

#pragma endregion Display & Adj Box Parameters

#pragma region RTC Support

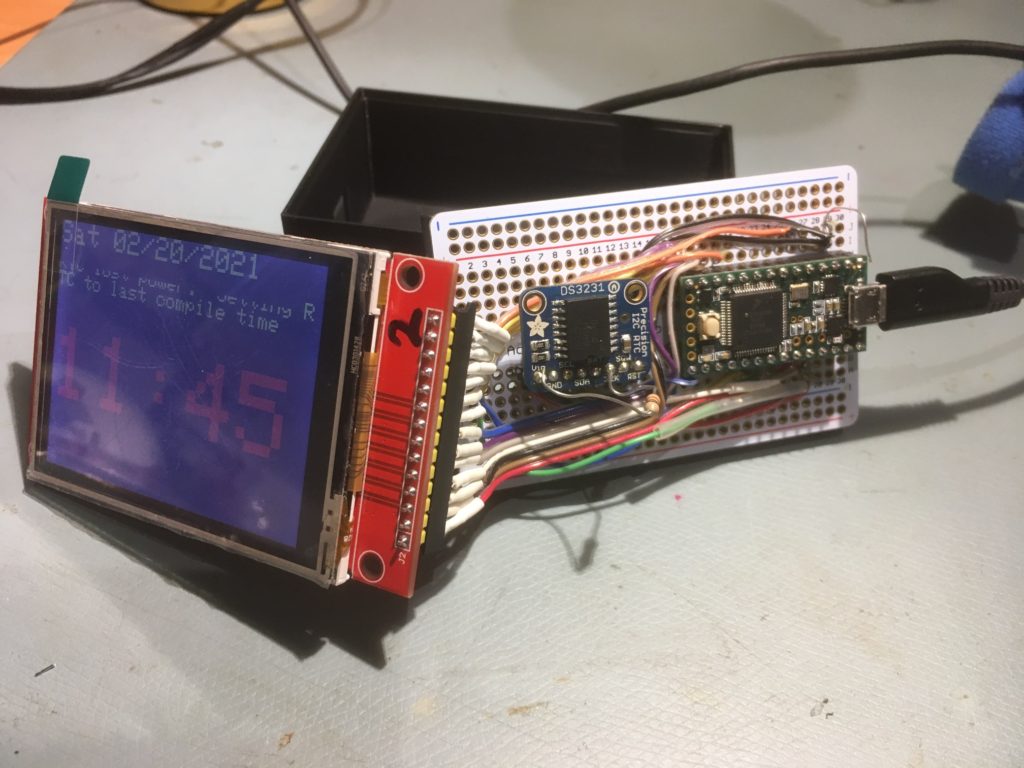

#define FORCE_RTC_TO_LAST_COMPILE_TIME //uncomment to manually set RTC to last compile time

RTC_DS3231 rtc;

char daysOfTheWeek[7][12] = { "Sun", "Mon", "Tue", "Wed", "Thu", "Fri", "Sat" };

DateTime now, lastTime;

char buffer[100];

int lasthour = 0; //02/15/21 added to refresh screen on the hour

struct tStamp

{

unsigned long mSec;

byte RTC_Status;

};

#define DS3231_ADDRESS 0x68 ///< I2C address for DS3231

#define DS3231_STATUSREG 0x0F ///< Status register

#define RTCStatArraySize 10

#define RTCStatTime_IntervalMsec 100

tStamp RTCStatArray[RTCStatArraySize];

#pragma endregion RTC Support

void setup()

{

Serial.begin(9600);

delay(3000);

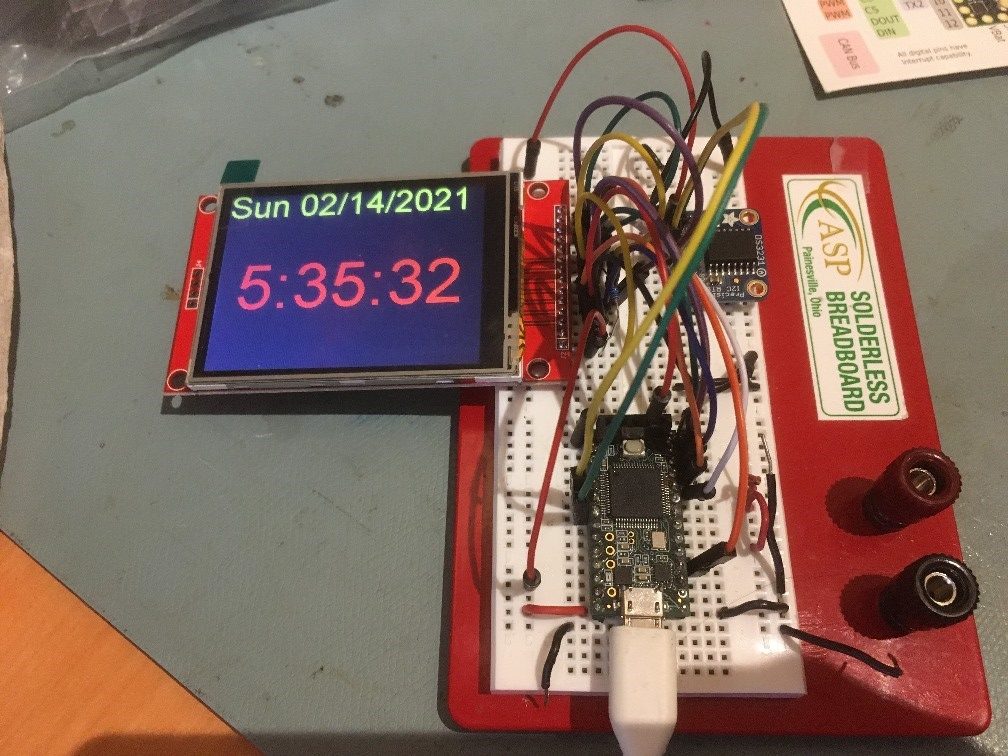

Serial.println("Teensy 3.2 TFT Clock Program");

#pragma region DISPLAY INITIALIZATION

Serial.println("Initializing TFT display");

tft.begin();

// Note: you can now set the SPI speed to any value

// the default value is 30Mhz, but most ILI9341 displays

// can handle at least 60Mhz and as much as 100Mhz

// tft.setClock(60000000);

tft.fillScreen(ILI9341_BLACK);

tft.setTextColor(ILI9341_YELLOW);

tft.setTextSize(2);

tft.setRotation(1);

#pragma endregion region DISPLAY INITIALIZATION

#pragma region TFT DIAGNOSTICS

#ifndef N0_DIAGNOSTICS

// read diagnostics (optional but can help debug problems)

uint8_t x = tft.readcommand8(ILI9341_RDMODE);

Serial.print("Display Power Mode: 0x"); Serial.println(x, HEX);

x = tft.readcommand8(ILI9341_RDMADCTL);

Serial.print("MADCTL Mode: 0x"); Serial.println(x, HEX);

x = tft.readcommand8(ILI9341_RDPIXFMT);

Serial.print("Pixel Format: 0x"); Serial.println(x, HEX);

x = tft.readcommand8(ILI9341_RDIMGFMT);

Serial.print("Image Format: 0x"); Serial.println(x, HEX);

x = tft.readcommand8(ILI9341_RDSELFDIAG);

Serial.print("Self Diagnostic: 0x"); Serial.println(x, HEX);

Serial.println(F("Benchmark Time (microseconds)"));

Serial.print(F("Screen fill "));

Serial.println(testFillScreen());

delay(200);

Serial.print(F("Text "));

Serial.println(testText());

delay(600);

Serial.print(F("Proportional Text "));

Serial.println(testProportionalText());

delay(600);

Serial.print(F("Lines "));

Serial.println(testLines(ILI9341_CYAN));

delay(200);

Serial.print(F("Horiz/Vert Lines "));

Serial.println(testFastLines(ILI9341_RED, ILI9341_BLUE));

delay(200);

Serial.print(F("Rectangles (outline) "));

Serial.println(testRects(ILI9341_GREEN));

delay(200);

Serial.print(F("Rectangles (filled) "));

Serial.println(testFilledRects(ILI9341_YELLOW, ILI9341_MAGENTA));

delay(200);

Serial.print(F("Circles (filled) "));

Serial.println(testFilledCircles(10, ILI9341_MAGENTA));

Serial.print(F("Circles (outline) "));

Serial.println(testCircles(10, ILI9341_WHITE));

delay(200);

Serial.print(F("Triangles (outline) "));

Serial.println(testTriangles());

delay(200);

Serial.print(F("Triangles (filled) "));

Serial.println(testFilledTriangles());

delay(200);

Serial.print(F("Rounded rects (outline) "));

Serial.println(testRoundRects());

delay(200);

Serial.print(F("Rounded rects (filled) "));

Serial.println(testFilledRoundRects());

delay(200);

Serial.println(F("Done!"));

#endif // !N0_DIAGNOSTICS

#pragma endregion region TFT DIAGNOSTICS

#pragma region RTC_SETUP

DateBox.Draw(&tft); //erase previous text

tft.setCursor(0, 0);

Serial.println("Initializing RTC...");

//tft.println("Initializing RTC...");

delay(1000);

if (!rtc.begin())

{

DateBox.Draw(&tft); //erase previous text

tft.setCursor(0, 0);

Serial.println("Couldn't find RTC");

tft.println("Couldn't find RTC");

while (1);

}

bool lp = rtc.lostPower();

Serial.print("lostPower() reports "); Serial.println(lp);

DateBox.Draw(&tft); //erase previous text

tft.setCursor(0, 0);

tft.printf("lostPower() = %d\n", lp);

delay(1000);

if (rtc.lostPower())

{

Serial.println("RTC lost power. Setting RTC to last compile time");

DateBox.Draw(&tft); //erase previous text

tft.setCursor(0, 0);

tft.println("RTC lost power. Setting RTC to last compile time");

// following line sets the RTC to the date & time this sketch was compiled

rtc.adjust(DateTime(F(__DATE__), F(__TIME__)));

}

#ifdef FORCE_RTC_TO_LAST_COMPILE_TIME

Serial.println("Forcing RTC to last compile time");

// following line sets the RTC to the date & time this sketch was compiled

rtc.adjust(DateTime(F(__DATE__), F(__TIME__)));

#endif //

//DateTime now = rtc.now();

now = rtc.now();

memset(buffer, '\0', 100);

GetDayDateTimeStringFromDateTime(now, buffer);

Serial.println("Retrieving Date/Time from RTC....");

Serial.print("Date String = "); Serial.println(buffer);

#pragma endregion RTC_SETUP

//DEBUG!!

//tft.println("Setting time to just before midnight");

//rtc.adjust(DateTime(2021, 02, 13, 00, 59, 45));

//DEBUG!!

//02/15/21 needed detect hour changes for screen refresh

now = rtc.now();

lasthour = now.hour();

mSecSinceLastClockUpdate = 0; //used to space out clock updates in loop()

}

void loop(void)

{

//Serial.printf("%lu: mSecSinceLastClockUpdate = %lu\n", millis(), (long int)mSecSinceLastClockUpdate);

delay(100);

//see if there is a touch anywhere

if (ts.touched())

{

mSecSinceLastTouch = 0; //reset the timeout watchdog

while (mSecSinceLastTouch < TOUCH_TIMEOUT_MSEC)

{

//Serial.printf("mSecSinceLastTouch = %lu\n", (unsigned long int)mSecSinceLastTouch);

TS_Point Tp = ts.getPoint();// Retrieve the touch point

if (Tp.z > 1000)

{

mSecSinceLastTouch = 0; //reset the timeout watchdog

TS_Point Dp = GetTouchPointInDisplayCoords(Tp);

CurAdjState = (AdjustmentState)AdjustTimeAndDate(Dp);

Serial.printf("Tp.z = %d: AdjustTimeAndDate(%d, %d) returns %s\n", Tp.z, Dp.x, Dp.y, AdjValNameArray[(int)CurAdjState]);

if (CurAdjState > ADJ_NONE)

{

ShowLongTimeDisplay();

ShowAdjButtons();

}

}

}

HideButtons();

HideHighlightBars();

ShowNormalTimeDisplay();

ShowDateDisplay();

CurAdjState = ADJ_NONE;

mSecSinceLastClockUpdate = 0;

}

if (mSecSinceLastClockUpdate > CLOCK_UPDATE_MSEC)

{

mSecSinceLastClockUpdate -= CLOCK_UPDATE_MSEC;

now = rtc.now();

ShowDateDisplay(); //Display day and date

//Display time

if (CurAdjState > ADJ_NONE)

{

ShowLongTimeDisplay();

}

else

{

ShowNormalTimeDisplay();

}

}

}

#pragma region DATE_TIME_FUNCTIONS

void GetDayDateTimeStringFromDateTime(DateTime dt, char* bufptr)

{

int mydayofweek = dt.dayOfTheWeek();

//mydayofweek = (mydayofweek < 0) ? 0 : mydayofweek; //guard for return of 0 from weekday()

int myday = dt.day();

int mymonth = dt.month();

int myyear = dt.year();

int myhour = dt.hour();

int mymin = dt.minute();

int mysec = dt.second();

char* dayofweek = (char*)daysOfTheWeek[mydayofweek];

sprintf(bufptr, "%s %4d/%02d/%02d at %02d:%02d:%02d", dayofweek, mymonth, myday, myyear, myhour, mymin, mysec);

}

void HourStringFromDateTime(DateTime dt, char* bufptr)

{

int hourval = dt.hour();

if (hourval > 12)

{

hourval -= 12;

}

//sprintf(bufptr, "%02d", hourval);

sprintf(bufptr, "%d", hourval);

}

void MinuteStringFromDateTime(DateTime dt, char* bufptr)

{

sprintf(bufptr, "%02d", dt.minute());

}

#pragma endregion DATE_TIME_FUNCTIONS

AdjustmentState AdjustTimeAndDate(TS_Point Dp)

{

AdjustmentState adjstate = ADJ_NONE;

DateTime newtime;

DateTime now = rtc.now();

int new_hour = 0; int new_minute = 0; int new_month = 0; int new_day = 0;

int cur_day = 0; //added 07/13/21

//Serial.printf("In AdjustTimeAndDate with CurAdjState = %d, at point (%d,%d)\n", CurAdjState, Dp.x, Dp.y);

switch (CurAdjState)

{

case ADJ_NONE:

if (TimeBox.TouchHit(Dp.x, Dp.y))

{

adjstate = ADJ_HOUR; //always start with hour

ShowHighlightBar(ADJ_HOUR);

}

else if (DateBox.TouchHit(Dp.x, Dp.y))

{

adjstate = ADJ_MONTH; //always start with month

ShowHighlightBar(ADJ_MONTH);

}

break;

case ADJ_HOUR:

Serial.print("In AdjustTimeAndDate ADJ_HOUR case\n");

adjstate = ADJ_HOUR;

if (PlusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Plus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("Old time is %d/%d/%d %d:%d\n", now.month(), now.day(), now.year(), now.hour(), now.minute());

new_hour = now.hour() + 1;

if (new_hour >= 24)

{

new_hour -= 24;

}

newtime = DateTime(now.year(), now.month(), now.day(), new_hour, now.minute(), now.second());

Serial.printf("New time is %d/%d/%d %d:%d\n", newtime.month(), newtime.day(), newtime.year(), newtime.hour(), newtime.minute());

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("RTC now set to %d/%d/%d %d:%d\n", now.day(), now.month(), now.year(), now.hour(), now.minute());

ShowLongTimeDisplay();

delay(500); //delay for a while to avoid multiple 'add' operations

}

else if (MinusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Minus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("Old time is %d/%d/%d %d:%d\n", now.month(), now.day(), now.year(), now.hour(), now.minute());

new_hour = now.hour() - 1;

if (new_hour < 0)

{

new_hour += 24;

}

newtime = DateTime(now.year(), now.month(), now.day(), new_hour, now.minute(), now.second());

Serial.printf("New time is %d/%d/%d %d:%d\n", newtime.month(), newtime.day(), newtime.year(), newtime.hour(), newtime.minute());

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("RTC now set to %d/%d/%d %d:%d\n", now.day(), now.month(), now.year(), now.hour(), now.minute());

ShowLongTimeDisplay();

delay(500); //delay for a while to avoid multiple 'add' operations

}

else if (NextBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Next box touch at (%d,%d)\n", Dp.x, Dp.y);

adjstate = ADJ_MIN;

ShowHighlightBar(ADJ_MIN);

delay(500); //prevent multiple NEXT transitions

}

break;

case ADJ_MIN:

Serial.print("In AdjustTimeAndDate ADJ_MIN case\n");

adjstate = ADJ_MIN;

if (PlusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Plus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("Old time is %d/%d/%d %2d:%2d\n", now.month(), now.day(), now.year(), now.hour(), now.minute());

new_minute = now.minute() + 1;

if (new_minute >= 60)

{

new_minute = 0;

}

newtime = DateTime(now.year(), now.month(), now.day(), now.hour(), new_minute, now.second());

Serial.printf("New time is %2d:%2d\n", newtime.hour(), newtime.minute());

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("RTC now set to %2d:%2d\n", now.day(), now.hour(), now.minute());

ShowLongTimeDisplay();

delay(500); //delay for a while to avoid multiple 'add' operations

}

else if (MinusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Minus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("ADJ_MIN case in DoMinusOp(). Decrementing Minute Value\n");

Serial.printf("Old time is %2d:%2d\n", now.hour(),now.minute());

new_minute = now.minute() - 1;

if (new_minute < 0)

{

Serial.printf("adjusting for 00/59 rollover\n");

new_minute = 59;

}

newtime = DateTime(now.year(), now.month(), now.day(), now.hour(), new_minute);

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("New time is %d:%d\n", now.hour(), now.minute());

Serial.printf("RTC now set to %2d:%2d\n", now.hour(), now.minute());

ShowLongTimeDisplay();

delay(500); //delay for a while to avoid multiple 'decrement' operations

}

else if (NextBox.TouchHit(Dp.x, Dp.y))

{

//Serial.printf("Next box touch at (%d,%d)\n", Dp.x, Dp.y);

adjstate = ADJ_SEC;

ShowHighlightBar(ADJ_SEC);

delay(500); //prevent multiple NEXT transitions

}

break;

case ADJ_SEC:

Serial.print("In AdjustTimeAndDate ADJ_SEC case\n");

adjstate = ADJ_SEC;

//both PLUS & MINUS operations simply reset seconds to zero

if (PlusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Plus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("Old time is %d/%d/%d %d:%d:%d\n", now.month(), now.day(), now.year(), now.hour(), now.minute(), now.second());

newtime = DateTime(now.year(), now.month(), now.day(), now.hour(), now.minute(), 0);

Serial.printf("New time is %d/%d/%d %d:%d:%d\n", newtime.month(), newtime.day(), newtime.year(), newtime.hour(), newtime.minute(), newtime.second());

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("RTC now set to %d/%d/%d %d:%d:%d\n", now.day(), now.month(), now.year(), now.hour(), now.minute(), now.second());

ShowLongTimeDisplay();

delay(500); //delay for a while to avoid multiple 'add' operations

}

else if (MinusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Minus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("Old time is %d/%d/%d %d:%d:%d\n", now.month(), now.day(), now.year(), now.hour(), now.minute(), now.second());

newtime = DateTime(now.year(), now.month(), now.day(), now.hour(), now.minute(), 0);

Serial.printf("New time is %d/%d/%d %d:%d:%d\n", newtime.month(), newtime.day(), newtime.year(), newtime.hour(), newtime.minute(), newtime.second());

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("RTC now set to %d/%d/%d %d:%d:%d\n", now.day(), now.month(), now.year(), now.hour(), now.minute(), now.second());

ShowLongTimeDisplay();

delay(500); //delay for a while to avoid multiple 'add' operations

}

else if (NextBox.TouchHit(Dp.x, Dp.y))

{

//Serial.printf("Next box touch at (%d,%d)\n", Dp.x, Dp.y);

adjstate = ADJ_HOUR;

ShowHighlightBar(ADJ_HOUR);

delay(500); //prevent multiple NEXT transitions

}

break;

case ADJ_DAYOFWEEK:

break;

case ADJ_MONTH: //07/13/21 rev to watch for next/prev month max days

Serial.print("In AdjustTimeAndDate ADJ_MONTH case\n");

adjstate = ADJ_MONTH;

if (PlusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Plus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("Old time is %d/%d/%d %d:%d\n", now.month(), now.day(), now.year(), now.hour(), now.minute());

new_month = now.month() + 1;

if (new_month > 12)

{

new_month = 1; //07/13/21 bugfix

}

//07/13/21 have to adjust if current dayval > max for new month

cur_day = now.day();

if (cur_day > aDaysInMonth[new_month - 1])

{

Serial.printf("%d Exceeds max days for new month (%d for %d)\n", cur_day, aDaysInMonth[new_month - 1], new_month);

new_day = aDaysInMonth[new_month - 1];

}

else

{

new_day = cur_day;

}

newtime = DateTime(now.year(), new_month, new_day, now.hour(), now.minute(), now.second());

Serial.printf("New time is %d/%d/%d %2d:%2d\n", newtime.month(), newtime.day(), newtime.year(), newtime.hour(), newtime.minute());

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("RTC now set to %d/%d/%d %2d:%2d\n", now.month(), now.day(), now.year(), now.hour(), now.minute());

ShowDateDisplay();

delay(500); //delay for a while to avoid multiple 'add' operations

}

else if (MinusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Minus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("Old time is %d/%d/%d %2d:%2d\n", now.month(), now.day(), now.year(), now.hour(), now.minute());

new_month = now.month() - 1;

/*new_month = (new_month <= 0) ? 12 : new_month; */

if (new_month <= 0)

{

new_month = 12; //no need to check max days, as feb max is 28 and dec max is 31

}

else

{

//have to check max days for new month

cur_day = now.day();

if (cur_day > aDaysInMonth[new_month - 1])

{

Serial.printf("%d Exceeds max days for new month (%d for %d)\n", cur_day, aDaysInMonth[new_month - 1], new_month);

new_day = aDaysInMonth[new_month - 1];

}

else new_day = cur_day;

}

//newtime = DateTime(now.year(), new_month, now.day(), now.hour(), now.minute(), now.second());

newtime = DateTime(now.year(), new_month, new_day, now.hour(), now.minute(), now.second());

Serial.printf("New time is %d/%d/%d %2d:%2d\n", newtime.month(), newtime.day(), newtime.year(), newtime.hour(), newtime.minute());

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("RTC now set to %d/%d/%d %2d:%2d\n", now.day(), now.month(), now.year(), now.hour(), now.minute());

ShowDateDisplay();

delay(500); //delay for a while to avoid multiple 'add' operations

}

else if (NextBox.TouchHit(Dp.x, Dp.y))

{

//Serial.printf("Next box touch at (%d,%d)\n", Dp.x, Dp.y);

adjstate = ADJ_DAY;

ShowHighlightBar(ADJ_DAY);

delay(500); //prevent multiple NEXT transitions

}

break;

case ADJ_DAY:

Serial.print("In AdjustTimeAndDate ADJ_DAY case\n");

adjstate = ADJ_DAY;

if (PlusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Plus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("Old time is %d/%d/%d %2d:%2d\n", now.month(), now.day(), now.year(), now.hour(), now.minute());

new_day = AdjustDayValue(now.month(), now.day() + 1); //not all months have same number of days

newtime = DateTime(now.year(), now.month(), new_day, now.hour(), now.minute(), now.second());

Serial.printf("New time is %d/%d/%d %d:%d\n", newtime.month(), newtime.day(), newtime.year(), newtime.hour(), newtime.minute());

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("RTC now set to %d/%d/%d %d:%d\n", now.day(), now.month(), now.year(), now.hour(), now.minute());

ShowDateDisplay();

delay(500); //delay for a while to avoid multiple 'add' operations

}

else if (MinusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Minus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("Old time is %d/%d/%d %d:%d\n", now.month(), now.day(), now.year(), now.hour(), now.minute());

new_day = now.day() - 1;

new_day = (new_day <= 0) ? aDaysInMonth[now.month() - 1] : new_day;

newtime = DateTime(now.year(), now.month(), new_day, now.hour(), now.minute(), now.second());

Serial.printf("New time is %d/%d/%d %d:%d\n", newtime.month(), newtime.day(), newtime.year(), newtime.hour(), newtime.minute());

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("RTC now set to %d/%d/%d %d:%d\n", now.day(), now.month(), now.year(), now.hour(), now.minute());

ShowDateDisplay();

delay(500); //delay for a while to avoid multiple 'add' operations

}

else if (NextBox.TouchHit(Dp.x, Dp.y))

{

//Serial.printf("Next box touch at (%d,%d)\n", Dp.x, Dp.y);

adjstate = ADJ_YEAR;

ShowHighlightBar(ADJ_YEAR);

delay(500); //prevent multiple NEXT transitions

}

break;

case ADJ_YEAR:

Serial.print("In AdjustTimeAndDate ADJ_YEAR case\n");

adjstate = ADJ_YEAR;

if (PlusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Plus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("Old time is %d/%d/%d %2d:%2d\n", now.month(), now.day(), now.year(), now.hour(), now.minute());

newtime = DateTime(now.year() + 1, now.month(), now.day(), now.hour(), now.minute(), now.second());

Serial.printf("New time is %d/%d/%d %2d:%2d\n", newtime.month(), newtime.day(), newtime.year(), newtime.hour(), newtime.minute());

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("RTC now set to %d/%d/%d %2d:%2d\n", now.month(), now.day(), now.year(), now.hour(), now.minute());

ShowDateDisplay();

delay(500); //delay for a while to avoid multiple 'add' operations

}

else if (MinusBox.TouchHit(Dp.x, Dp.y))

{

Serial.printf("Minus box touch at (%d,%d)\n", Dp.x, Dp.y);

Serial.printf("Old time is %d/%d/%d %2d:%2d\n", now.month(), now.day(), now.year(), now.hour(), now.minute());

newtime = DateTime(now.year() - 1, now.month(), now.day(), now.hour(), now.minute(), now.second());

Serial.printf("New time is %d/%d/%d %2d:%2d\n", newtime.month(), newtime.day(), newtime.year(), newtime.hour(), newtime.minute());

rtc.adjust(newtime);

now = rtc.now();

Serial.printf("RTC now set to %d/%d/%d %d:%d\n", now.day(), now.month(), now.year(), now.hour(), now.minute());

ShowDateDisplay();

delay(500); //delay for a while to avoid multiple 'add' operations

}

else if (NextBox.TouchHit(Dp.x, Dp.y))

{

//Serial.printf("Next box touch at (%d,%d)\n", Dp.x, Dp.y);

adjstate = ADJ_MONTH;

ShowHighlightBar(ADJ_MONTH);

delay(500); //prevent multiple NEXT transitions

}

break;

default:

break;

}

//Serial.printf("AdjustTimeAndDate(%d, %d) returns %d\n", Dp.x, Dp.y, (int)adjstate);

return adjstate;

}

#pragma region Helper Functions

TS_Point GetTouchPointInDisplayCoords(TS_Point Tp)

{

//Purpose: Retrieve a touch point in display coordinate system

//Inputs:

// Rotation value

// Mapping values

// TS_Point from touch chip

//Outputs:

// TS_Point object containing touch (X,Y) in display coordinates

//Plan:

// Step1: Retrieve touch point from touch chip

// Step2: Map to display coordinates taking rotation into account

//Step1: Retrieve touch point from touch chip

//TS_Point Tp = ts.getPoint();

TS_Point Dp;

//Step2: Map to display coordinates taking rotation into account

#ifdef SCREEN_ORIENTATION_1

Dp.x = map(Tp.x, TS_MAXX, TS_MINX, 0, tft.width());

Dp.y = map(Tp.y, TS_MAXY, TS_MINY, 0, tft.height());

#else

#endif

////DEBUG!!

//Serial.printf(" GetTouchPointInDisplayCoords: %lu\t%d\t%d\t%d\t%d\t%d\n",

// millis(), Tp.x, Tp.y, Tp.z, Dp.x, Dp.y);

////DEBUG!!

return Dp;

}

void ShowAdjButtons()

{

Serial.printf("In ShowAdjButtons\n");

HideButtons();

//03/13/21 new centering feature works great!

NextBox.Draw(&tft, "NEXT", ILI9341_BLACK, Arial_20, true);

PlusBox.Draw(&tft, "+", ILI9341_BLACK, Arial_40, true);

MinusBox.Draw(&tft, "-", ILI9341_BLACK, Arial_40, true);

}

void HideButtons()

{

PlusBox.Draw(&tft, ILI9341_BLACK);

MinusBox.Draw(&tft, ILI9341_BLACK);

NextBox.Draw(&tft, ILI9341_BLACK);

}

void ShowNormalTimeDisplay()

{

//Serial.printf("In ShowNormalTimeDisplay\n");

now = rtc.now();

int hournum = now.hour();

//guard against 1259->1300 && 2359->0000 transitions

if (hournum > 12)

{

hournum -= 12;

}

else if (hournum == 0)

{

hournum += 12;

}

hournum = (hournum > 12) ? hournum - 12 : hournum;

tft.setCursor(0, 100);

TimeBox.Draw(&tft); //redraws black background

tft.setTextColor(ILI9341_RED);

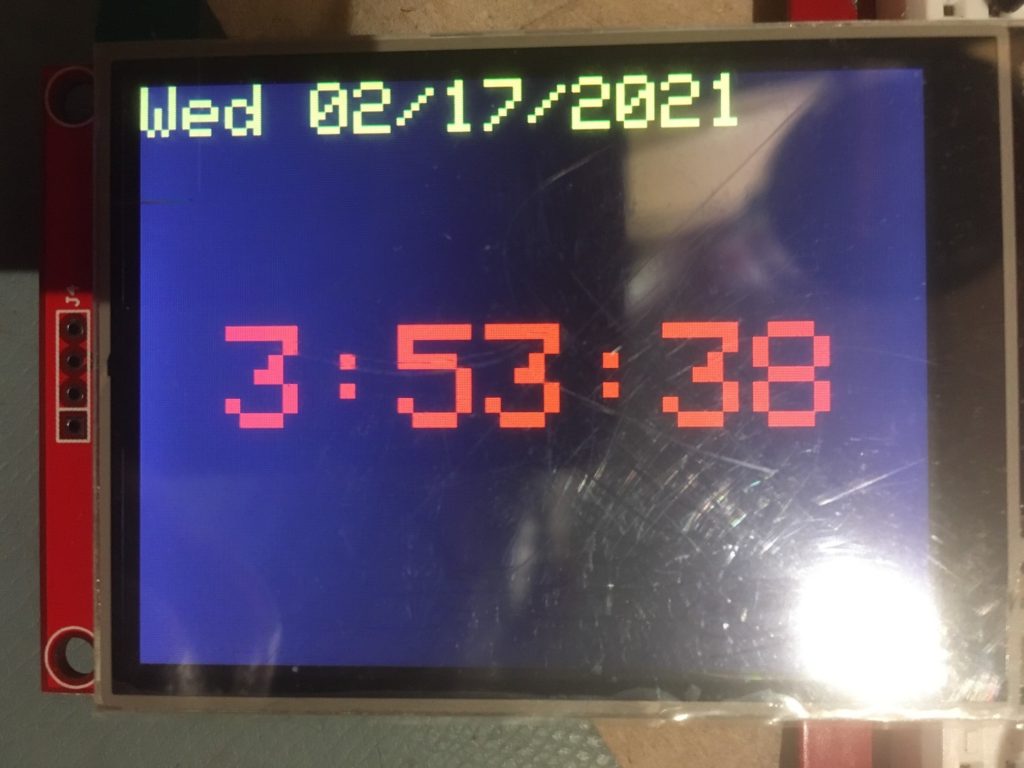

tft.setFont(Arial_72);

tft.setCursor(160, 120, true);//try the text centering feature

tft.printf("%2d:%02d", hournum, now.minute());

}

void ShowLongTimeDisplay()

{

//Serial.printf("In ShowLongTimeDisplay\n");

now = rtc.now();

tft.setTextColor(ILI9341_RED);

tft.setCursor(160, 120, true);//try the text centering feature

tft.setFont(Arial_60);

TimeBox.Draw(&tft); //redraws black background

int hournum = now.hour();

//guard against 1259->1300 && 2359->0000 transitions

if (hournum > 12)

{

hournum -= 12;

}

else if (hournum == 0)

{

hournum += 12;

}

hournum = (hournum > 12) ? hournum - 12 : hournum;

tft.printf("%2d:%02d:%02d", hournum, now.minute(), now.second());

}

void ShowHighlightBar(AdjustmentState adjstate)

{

switch (adjstate)

{

case ADJ_NONE:

Serial.printf("ADJ_NONE case in ShowHighlightBox()\n");

HideHighlightBars();

break;

case ADJ_HOUR:

HideHighlightBars();

HourHighlightBox.Draw(&tft);

break;

case ADJ_MIN:

HideHighlightBars();

MinuteHighlightBox.Draw(&tft);

break;

case ADJ_SEC:

HideHighlightBars();

SecondHighlightBox.Draw(&tft);

break;

case ADJ_DAYOFWEEK:

break;

case ADJ_MONTH:

HideHighlightBars();

MonthHighlightBox.Draw(&tft);

break;

case ADJ_DAY:

HideHighlightBars();

DayHighlightBox.Draw(&tft);

break;

case ADJ_YEAR:

HideHighlightBars();

YearHighlightBox.Draw(&tft);

break;

default:

break;

}

}

void HideHighlightBars()

{

tft.fillRect(0, DATE_HIGHLIGHT_BOX_YLOC, ALL_DATE_HIGHLIGHT_BOX_WIDTH, DATE_HIGHLIGHT_BOX_HEIGHT, ILI9341_BLACK);

tft.fillRect(0, TIME_HIGHLIGHT_BOX_YLOC, ALL_TIME_HIGHLIGHT_BOX_WIDTH, TIME_HIGHLIGHT_BOX_HEIGHT, ILI9341_BLACK);

}

void ShowDateDisplay()

{

DateTime now = rtc.now();

DateBox.Draw(&tft);

tft.setTextColor(ILI9341_YELLOW);

tft.setCursor(0, 0);

//tft.setTextSize(3);

tft.setFont(Arial_28);

tft.printf("%s %02d/%02d/%02d\n",

daysOfTheWeek[now.dayOfTheWeek()], now.month(), now.day(), now.year());

}

int AdjustDayValue(int month, int day)

{

//Notes:

// 07/13/21 rev to handle negative day values

if (day > aDaysInMonth[month - 1])

{

Serial.printf("%d is greater than max days (%d) for this month - setting to 1\n", day, aDaysInMonth[month - 1]);

return 1;

}

//07/13/21 bugfix

else if (day <= 0)

{

int newdaynum = aDaysInMonth[month - 1];

Serial.printf("%d is <= 0: set to max days (%d) for this month\n", day, newdaynum);

return newdaynum;

}

else

{

return day;

}

}

#pragma endregion Helper Functions