Posted 11 January 2017

I’ve had at least one 3D printer in my home laboratory for well over 2 years now, and having the ability to print up arbitrary 3D shapes has been a complete creative game-changer for me. Now when I have an idea about something I want to build or try, I don’t have to spend days in my shop trying to fabricate something out of wood or sheet metal – I can design it in TinkerCad and print it on my 3D printer. Moreover (and this is where it gets really cool!), I don’t have to get it right the first time – I can make an unlimited number of versions of the idea, improving and/or changing it as I go. Each iteration takes a few hours at most, and costs just a few pennies in terms of power and filament usage – what a deal!

Anyway, I have accumulated a number of rolls of different filaments, all of which degrade in greater or lesser degree over time due to moisture absorption (hygroscopic tendency). I

haven’t worried too much about this up to now, mostly because my lab is in an air-conditioned house in the midwest, where humidity levels are low to begin with. However, I recently started seeing some printing problems that led me to believe that I may need to address this issue. In my typically over-the-top fashion, I decided that if I was going to work this problem, I needed a way to monitor the actual temperature & humidity in whatever arrangement I tried.

First, as usual, I did some web research, and found a solution implemented by the folks at the Taulman specialty 3D filament fabrication house. Their solution was a 5-gallon plastic bucket with some air-holes, a 40-60 Watt lightbulb, and a wooden dowel. This allowed them to combine a dehumidifier with a filament delivery system. I fabricated one of these myself, but wasn’t particularly happy with the results. While it worked fine, there was only room for two rolls of filament at a time, while I have literally dozens of rolls of different filaments. In addition, I had no way of knowing what the actual temperature and relative humidity were inside the bucket – for all I knew, it could be doing nothing but wasting 40 watts of electricity!

So, I decided to combine my pile of 3D filaments, my 3D printing super-powers, and my Electrical Engineering Mad Scientist background to come up with a better solution to the filament drying problem.

Temperature/Humidity Sensors

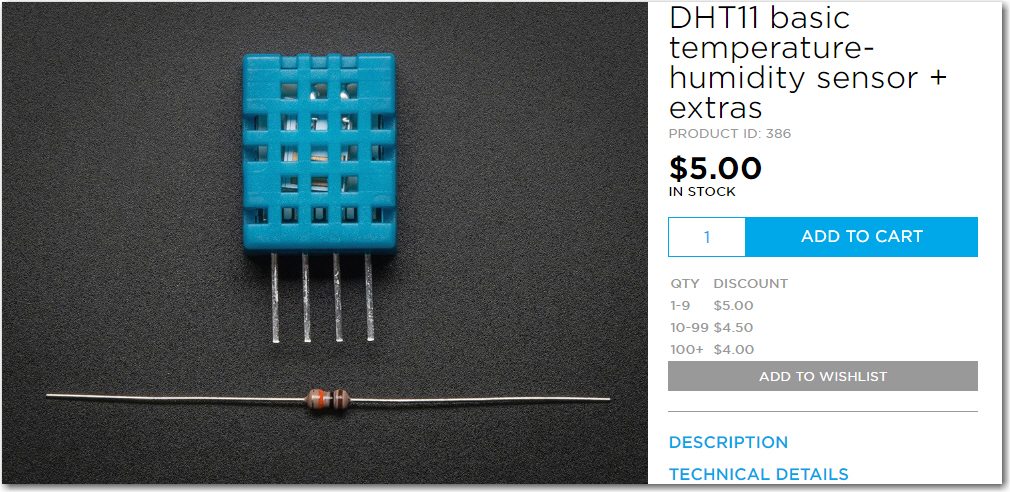

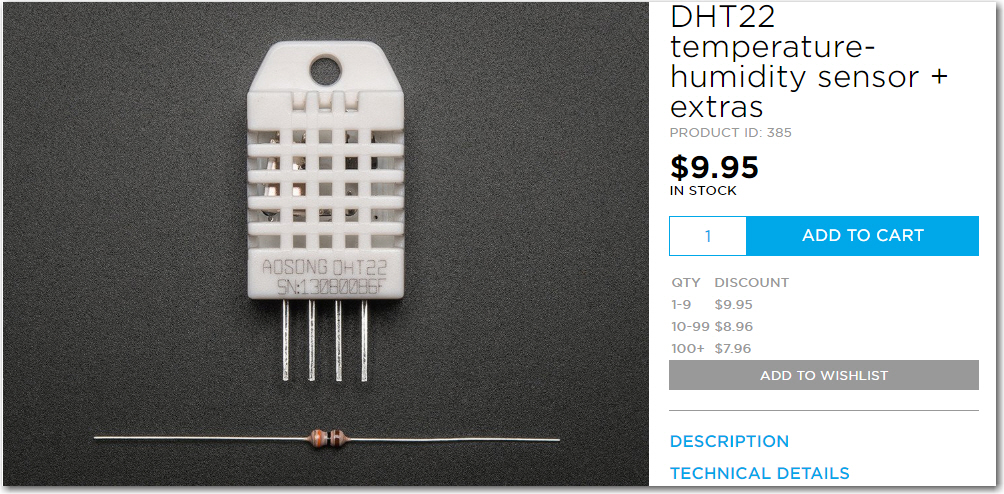

The DIY/Robotics/Hobbyist market has spawned all sorts of new capabilities, so I was not at all surprised to find that temperature/humidity sensors were cheap and readily available. I started with the cheaper DHT11 (I figured I would kill at least one sensor before getting it right), but later moved on to the DH22. The DH11 humidity measurement range stops at 20% on the low end, and since I am trying to obtain humidities at or below that value, I decided to blow out my sensor budget from around $5/unit to around $10 – a real budget-breaker (not)!

DHT11 Temp/Humidity sensor, shown here from Adafruit. 20-80% RH range with +/- 5% accuracy

DHT22 Temp/Humidity sensor, shown here from Adafruit. O-100% RH range with +/- 2.5% accuracy

Arduino Uno Controller

In order to effectively use the RH sensors, I needed a controller of some sort. Happily for me, there was already a DHT11/22 library available for the wonderful Arduino line of controllers, and I happened to have several Arduino Uno’s lying around waiting for something to do. Connecting up the sensor, and getting a program working was a matter of just a few lines, most of which had already been written in the form of an example program

8-Character LCD Display

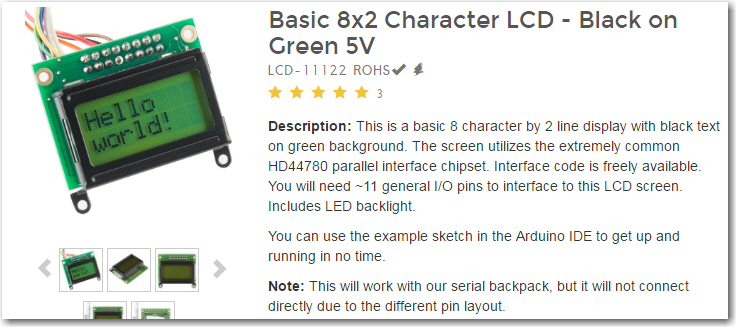

When I first started this project, I thought it would be adequate to simply connect the arduino to my PC to readout the data. This worked, but turned out to be cumbersome; I had to have a physical connection to the controller, which was located inside the dehumidifier bin. Later I tried a Wixel connection, which also worked, but still meant that I had to bring up a serial port app on my PC to find out what my dehumidifier bin was doing. What I really wanted was a completely self-contained system, so I could simply look at some sort of display on or in the bin and tell whether or not things were working. After doing a bit more web research, I found the Sparkfun ‘Basic 8-character LCD display’ for all of $4.95 (plus shipping). In addition, this display (plus a number of others with different character arrangements) were easily integrated into an Arduino program by means of the built-in ‘LiquidCrystal’ Library – nice!!

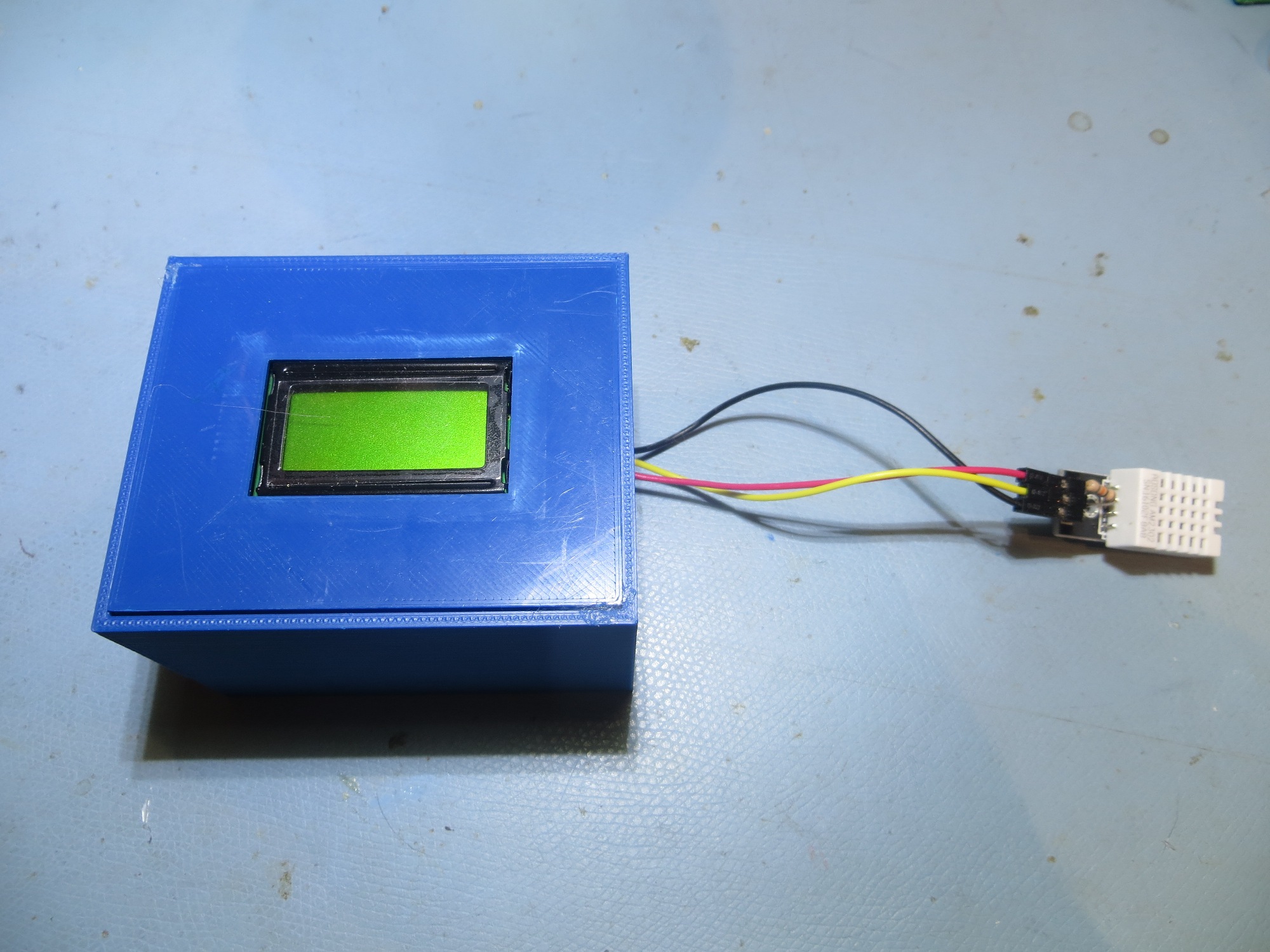

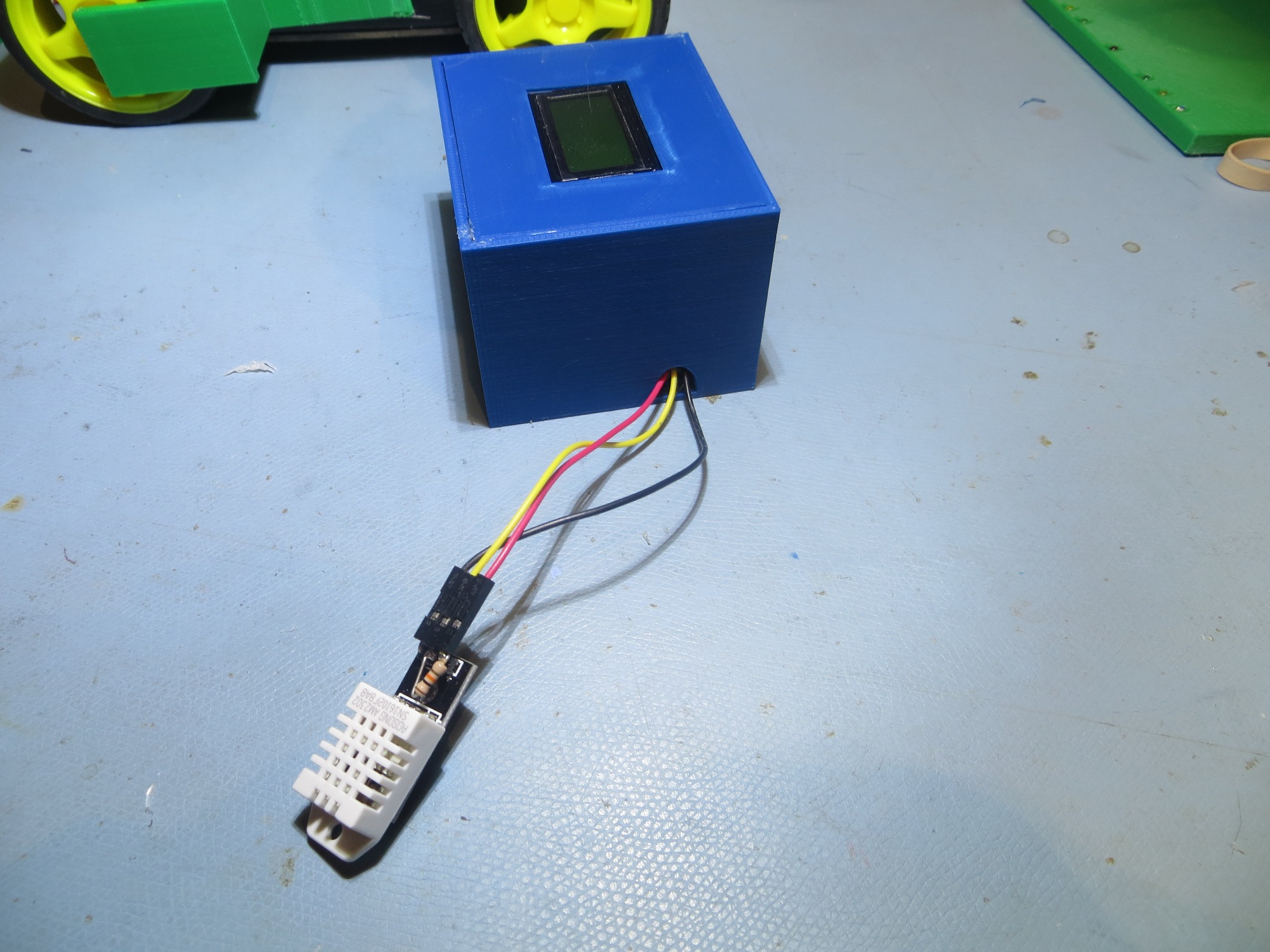

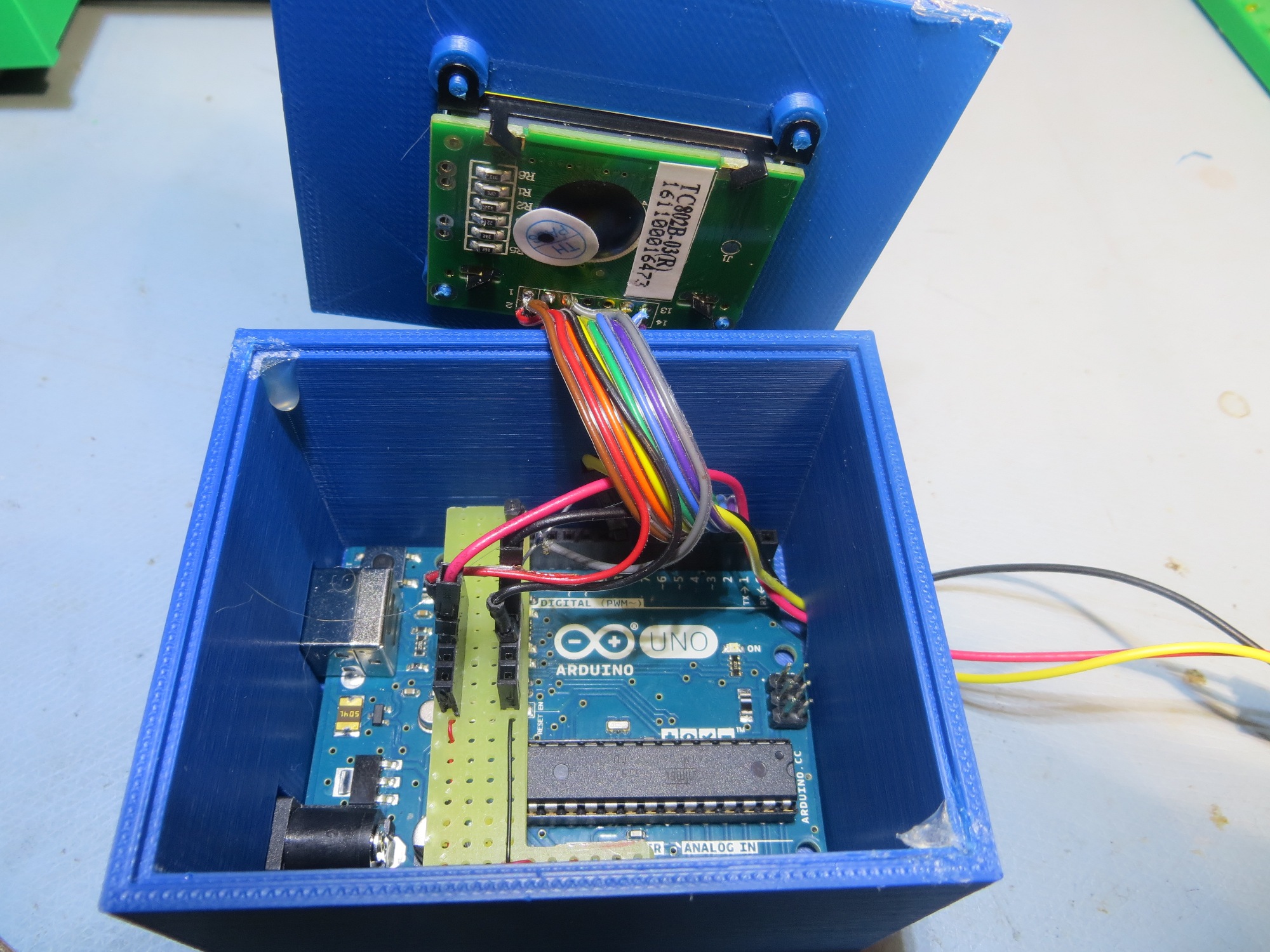

So now I had all the pieces – a sensor (DHT22), a controller (Arduino Uno), and a display for readout (Sparkfun 8×2 LCD). Now what I needed was a nice, custom-made box to house them, and just coincidentally I had 3D printer and LOTS of filament hanging around just waiting for a project! ;-). As usual, I went through several iterations (you would think that it would be pretty hard to screw up a simple box design, but I’m highly creative when it comes to finding new ways!). When I was finished, I had a nice little box with enough room for everything, a recessed lid, and appropriately placed holes for the power connector, the USB connector, and the sensor cable, as shown below

To complete the project, all I had to do was drill some holes in a handy transparent storage bin, load it up with filament rolls and a 40-watt trouble light, and set the sensor box inside where the readout would be visible from the outside. The whole thing was installed on a shelf over my workbench, so I can simply walk up to the bin and see the readout from eye level – neat!

Now all I have to do is wait a day or so to see where the system stabilizes, and make whatever airflow adjustments are necessary. For anyone who cares, I have included below the Arduino sketch for the project.

15 January 2017 Update: After 24 hours, the system stabilized to around 85 º F (29.4C) and about 26%, which I thought wasn’t enough better than room environment to make a difference, so I closed off about half of the air-holes. After another 24 hours or so, the system re-stabilized at about 90 º F (32.2C) and 21% humidity – much nicer!

17 February 2017 Cleanup: Here is the code to display temperature & humidity on the LCD display, and also make the data available at the serial port.

Frank