Posted 29 September 2019,

I got an email from Dr. Betty Lise Anderson of the Electrical Engineering Department (I think it’s actually Electrical and Computer Engineering now) at The Ohio State University, asking me if I still had the documentation for the speaker amplifiers I created a couple of years ago for her STEM outreach program. . Dr. Anderson said these units were very well-liked by her STEM outreach students; so well liked in fact that they apparently walked away on their own! She asked me if I would be willing to fabricate another couple of amps, and said she would happily pay for all the parts.

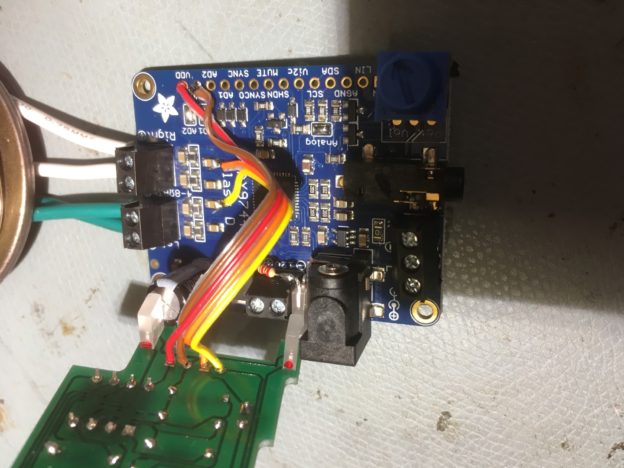

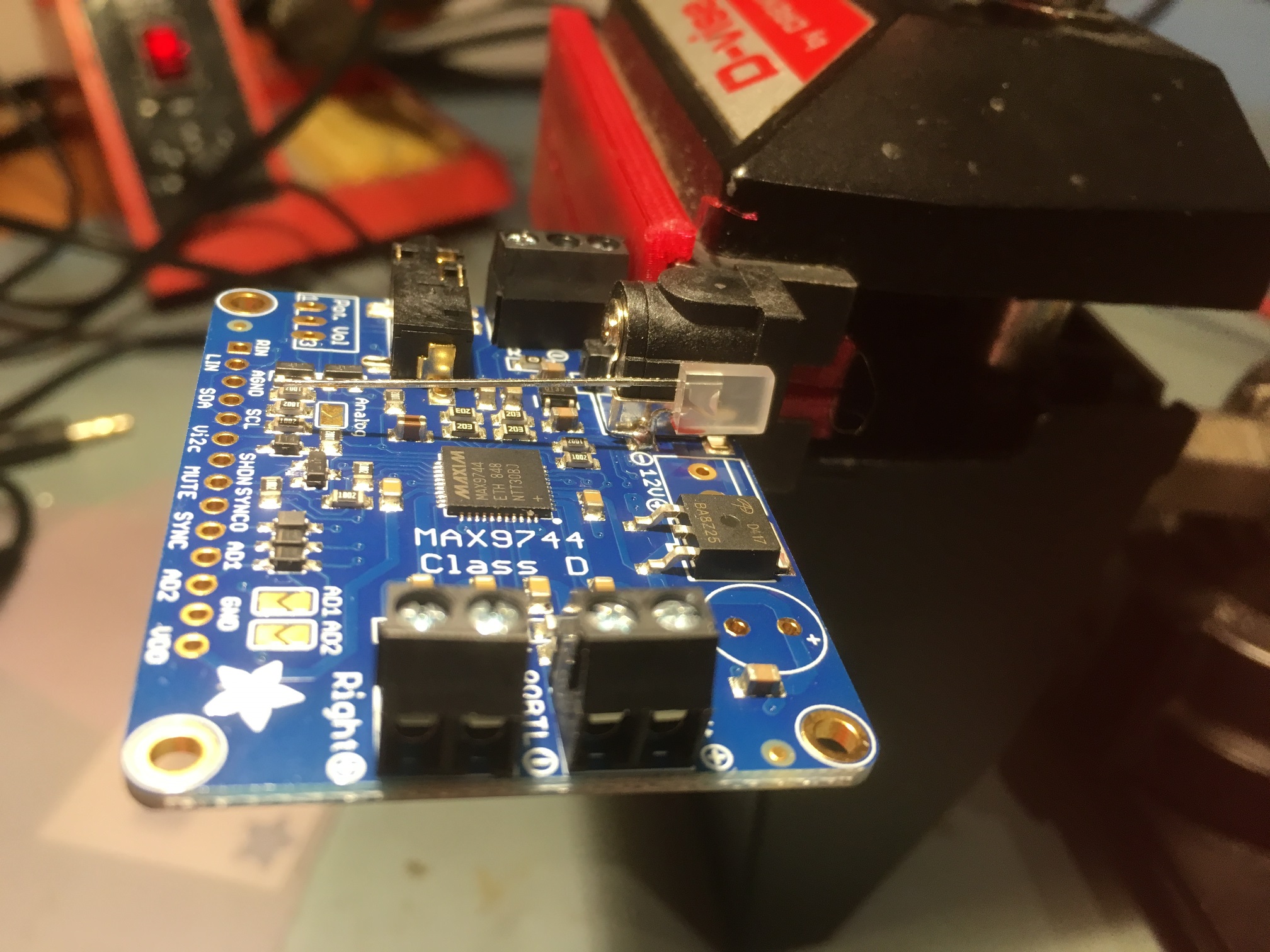

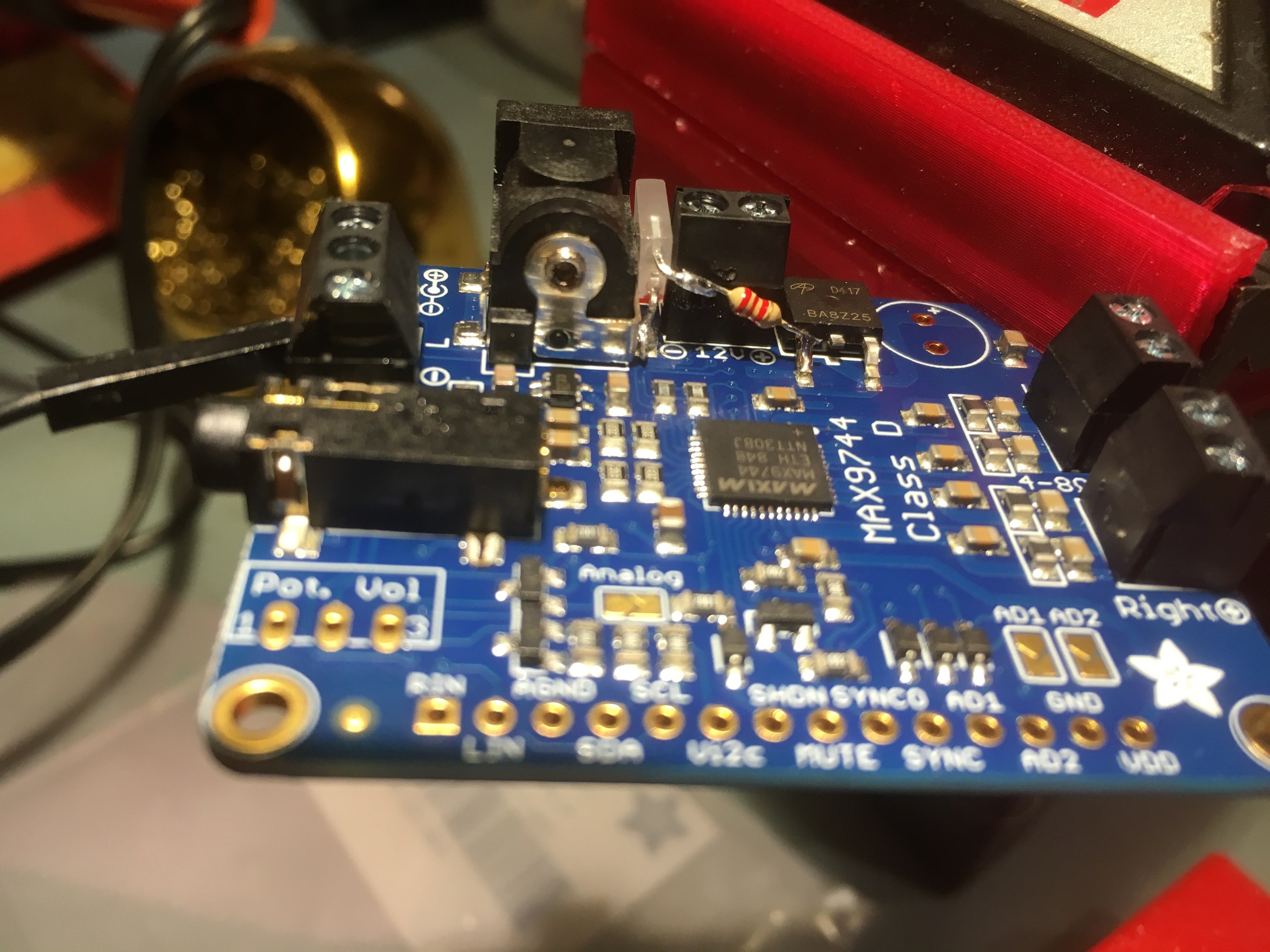

Since I never throw anything away, I did indeed have the documentation and even some remaining parts from the original project. I still had a half-dozen or so of the custom audio level indicator PCBs and at least one Adafruit 20W Class D amplifier left over. I figured I’d need a couple of wall-wart 12V power supplies and one more amplifier – everything else was already available in my parts bins. I figured the hundred bucks or so required to get all the parts was not worth worrying about, and besides I could probably write it off as advertising expense for EM Workbench LLC.

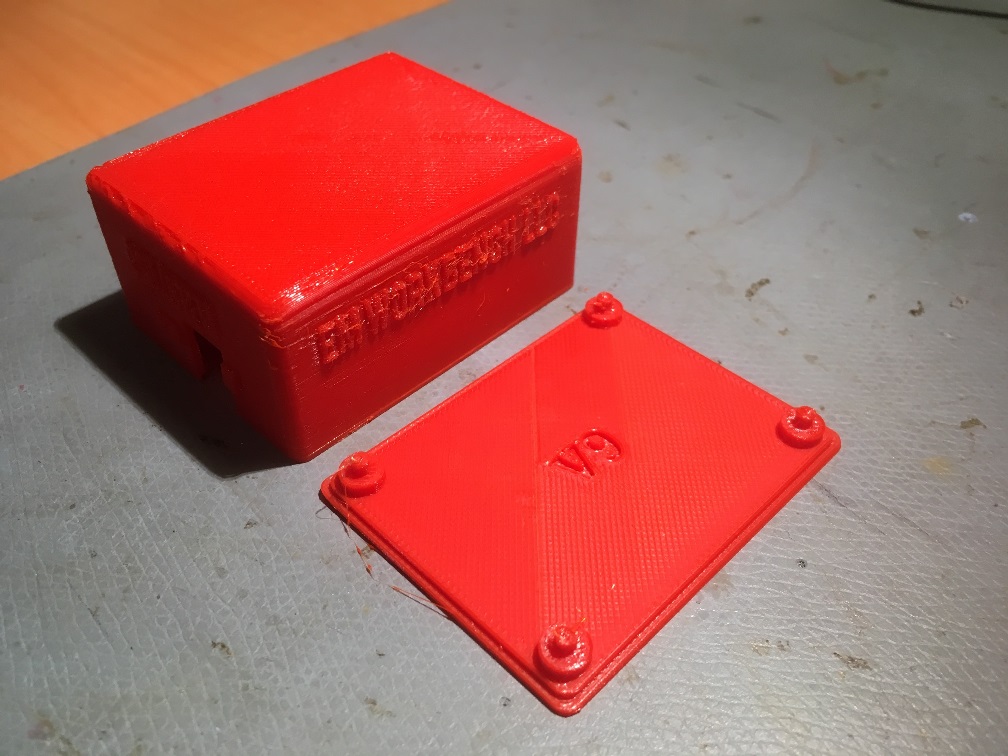

The enclosure:

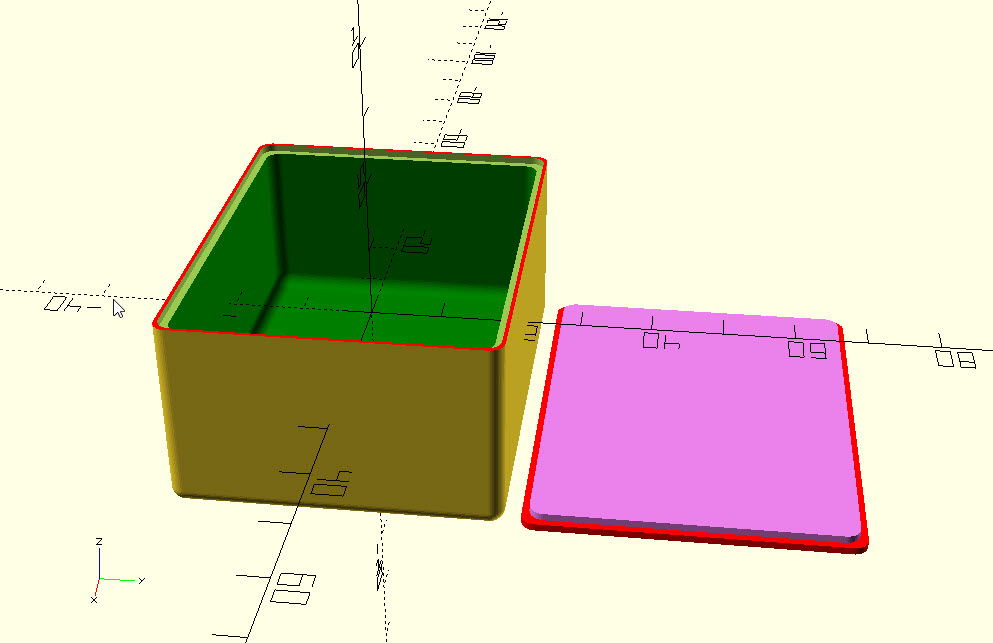

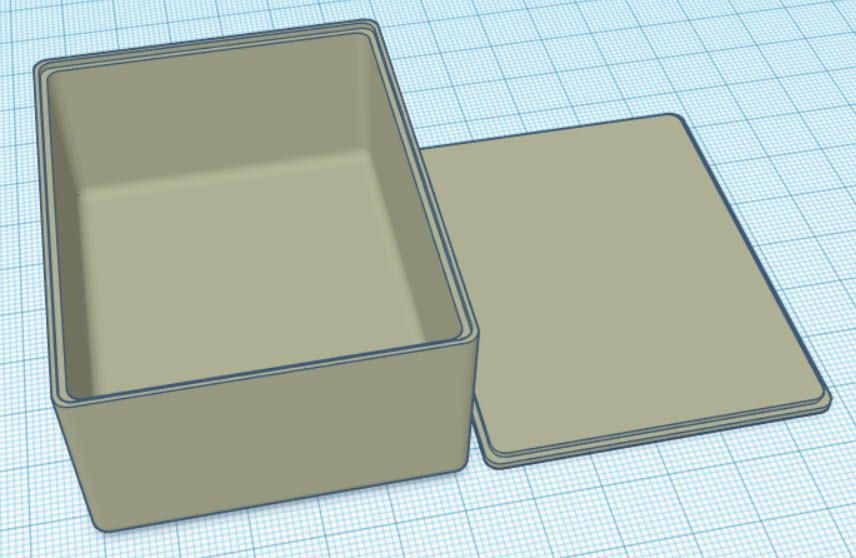

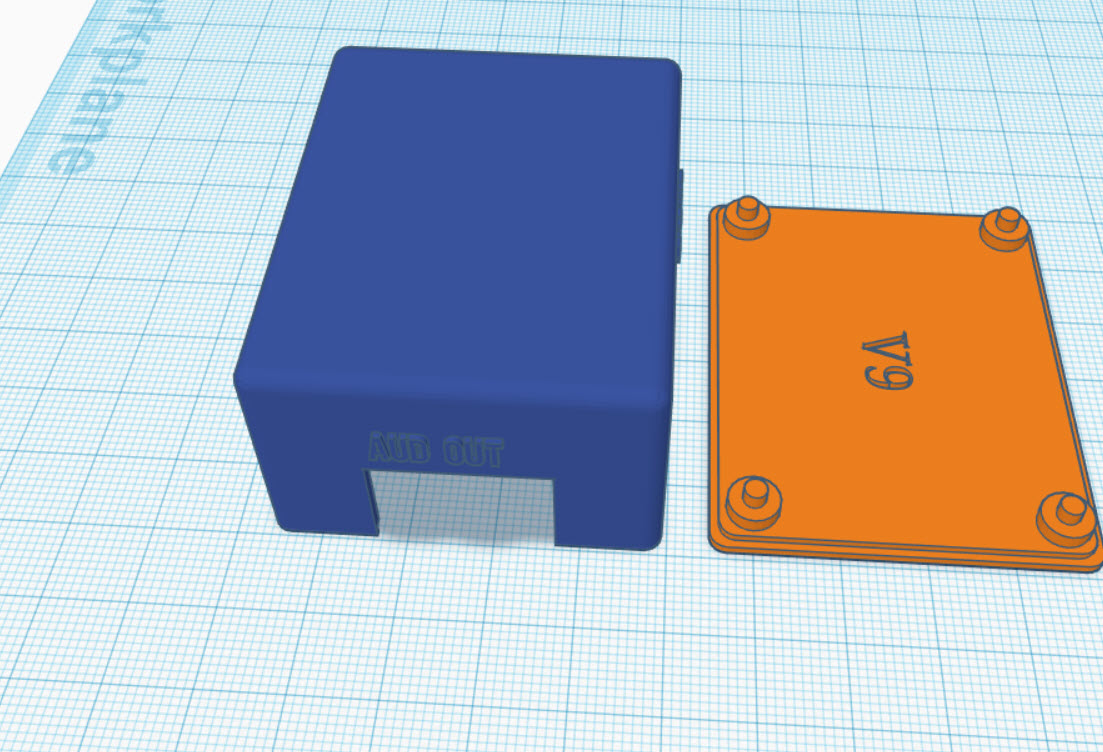

When I made the first set, I 3D printed an enclosure that was a modified version of the nice rounded-corner box design published by Adafruit for just the amplifier. However, when I tried this trick again, I wound up not liking the result. Instead, I decided I should be able to create my own rounded corner box. I searched around on Thingiverse and found a few parameterized rounded box designs, but they all seemed sort of half-baked. So I broke out my copy of Open SCAD and started figuring out how to do it myself. I ran across a video that demonstrated the rounded-corner technique using a ‘minkowski’ function, and then I was off and running. After just a few hours (OK, more than a few, but definitely less than infinity) I had coded a nice, compact Open SCAD module to generate an arbitrary shaped rounded-corner box with an optional companion nesting lid. The code is available on Thingiverse here. Using the Open SCAD module, I generated an enclosure and companion lid and exported the result as an STL file, which I then sucked into Tinkercad to add the required cutouts and such for the amplifier project.

Amplifier enclosure as generated in Open SCAD

Amplifier enclosure after importing the STL file into Tinkercad

Amplifier enclosure after modification for the Adafruit amplifier and level indicator PCB

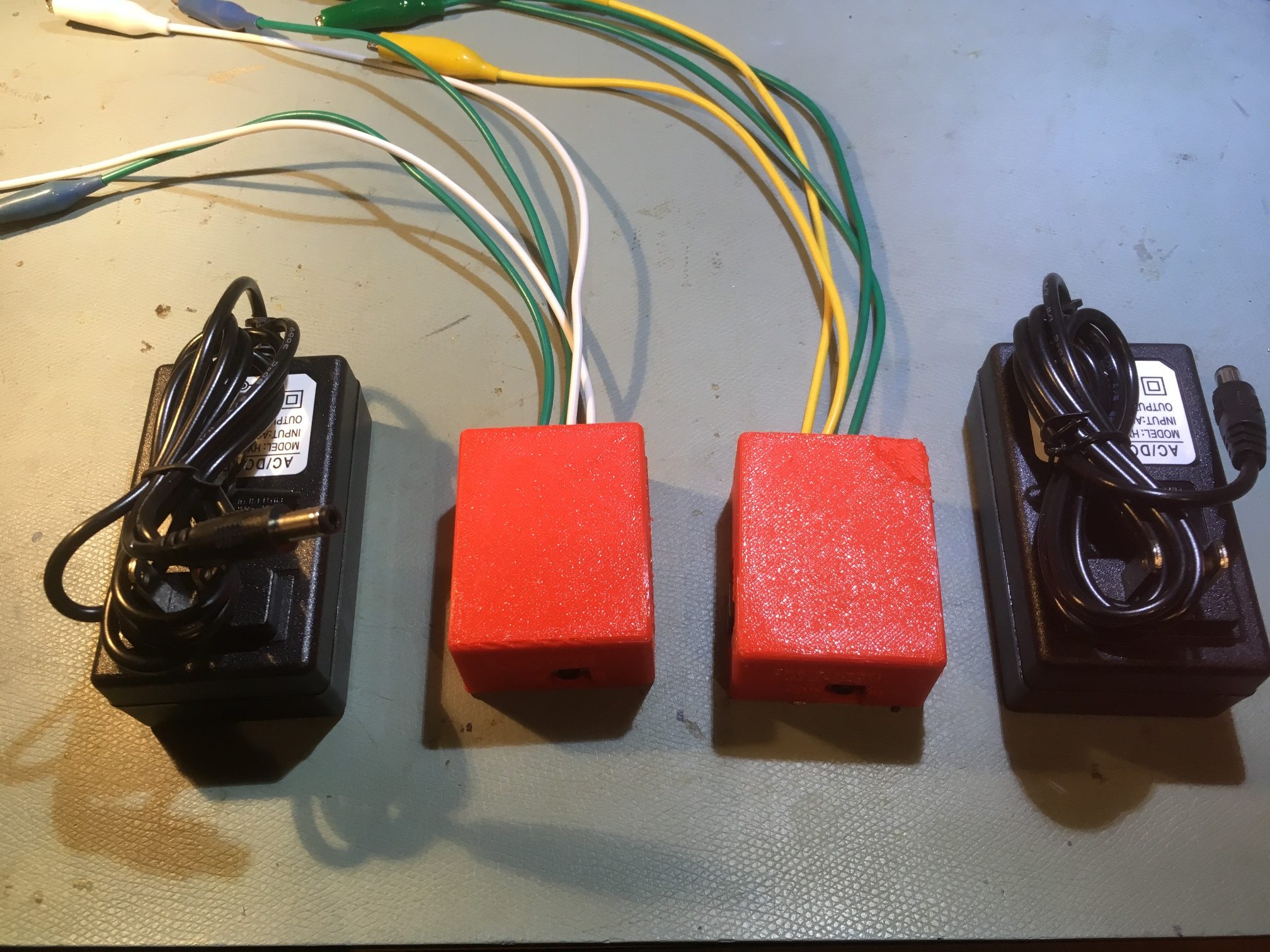

After getting the enclosure design all spiffed up, I started printing it on my trusty PowerSpec 3D Pro 3D printer, only to have it die on me – so much for ‘trusty’! This was not an entirely unexpected event, as I had been noticing a ‘burnt insulation’ smell coming from it over the last few weeks, and suspected that it might be on its last legs. So, this batch of amplifier enclosures would have to be single-color (the last one was dual-color red or the enclosure and gray for the text) – at least until my new MakerGear M3-ID 3D printer shows up :-)). Here’s the result.

Amplifier and Activity Indicator:

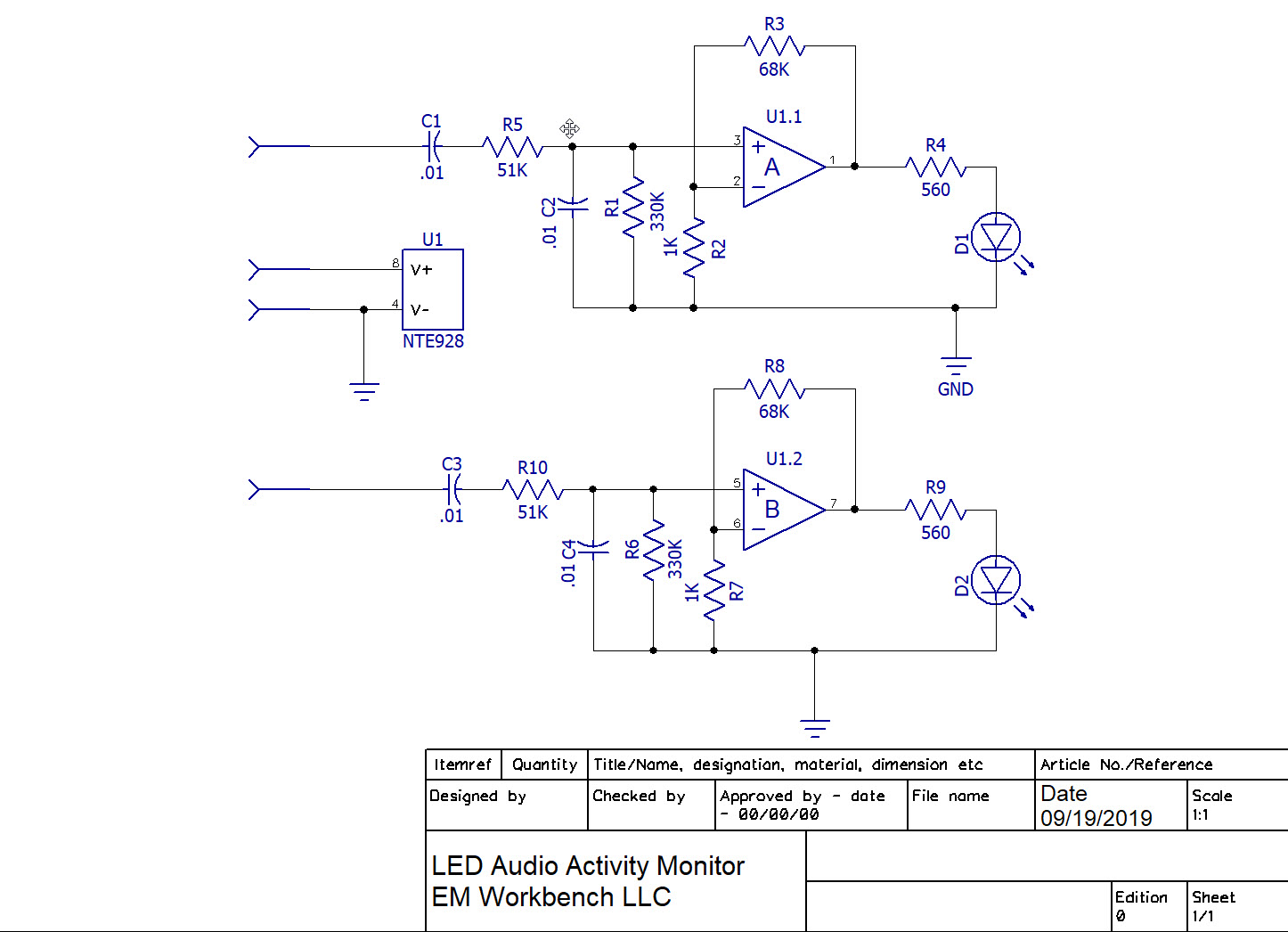

In reviewing the documentation from the original project, I saw that the activity indicator schematic wasn’t entirely accurate, so I brought it up to date – mostly cosmetic/lettering, but…

View showing power indicator LED installation before installing power input terminal connector

View showing 2.2K current limiting resistor for power indicator LED

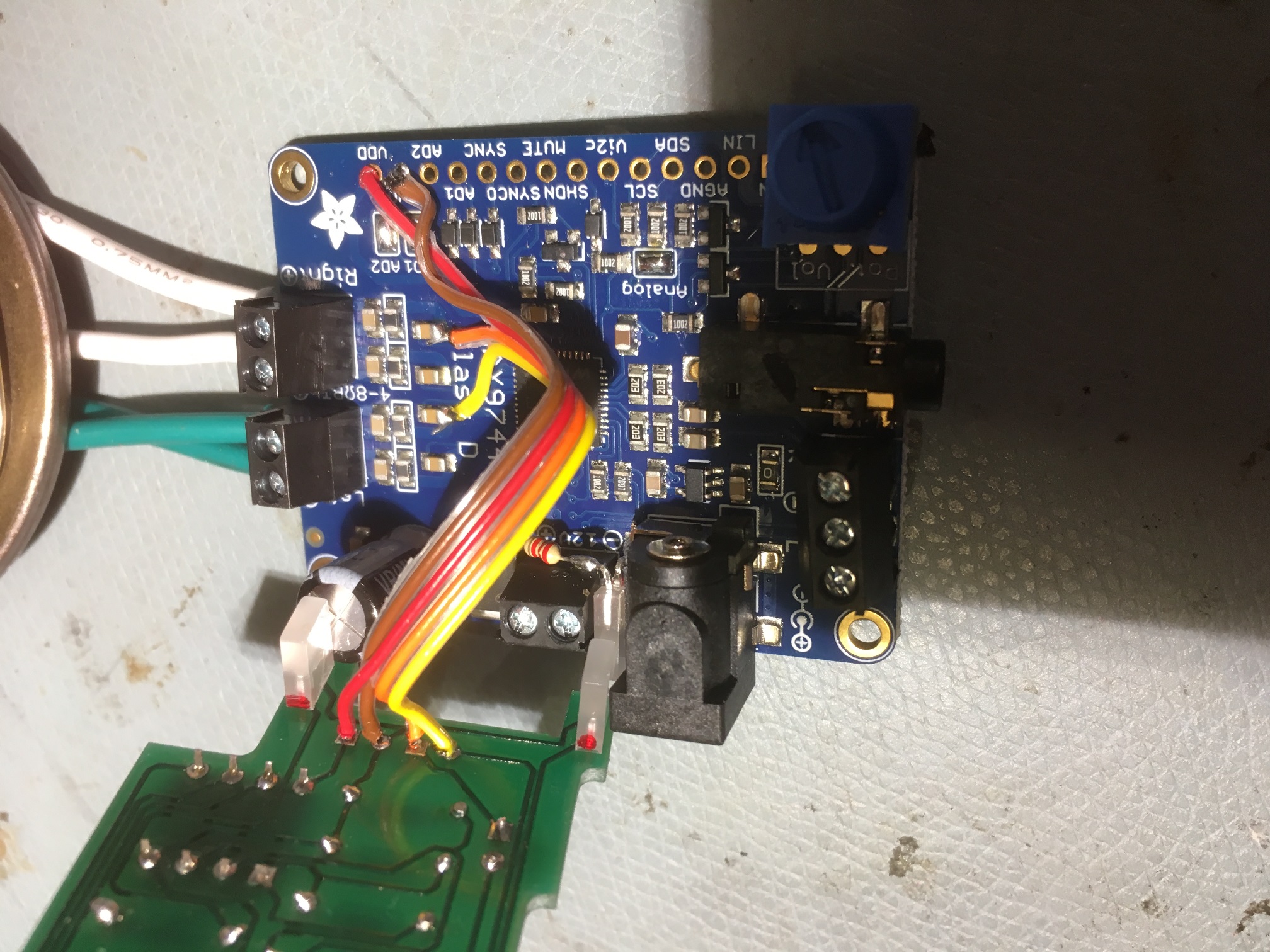

View showing connections between activity monitor PCB and amplifier board

The finished product:

Two complete amplifiers with companion power supplies

A large part of the motivation for this post was to thoroughly document all aspects of fabricating the second run of OSU/STEM speaker amplifiers, so that when I get that next call from Dr. Betty Lise Anderson… 😉

Frank