/*

Name: TeensyLowPowerDigitalScale.ino

Created: 12/2/2018 9:43:43 PM

Author: FRANKWIN10\Frank

*/

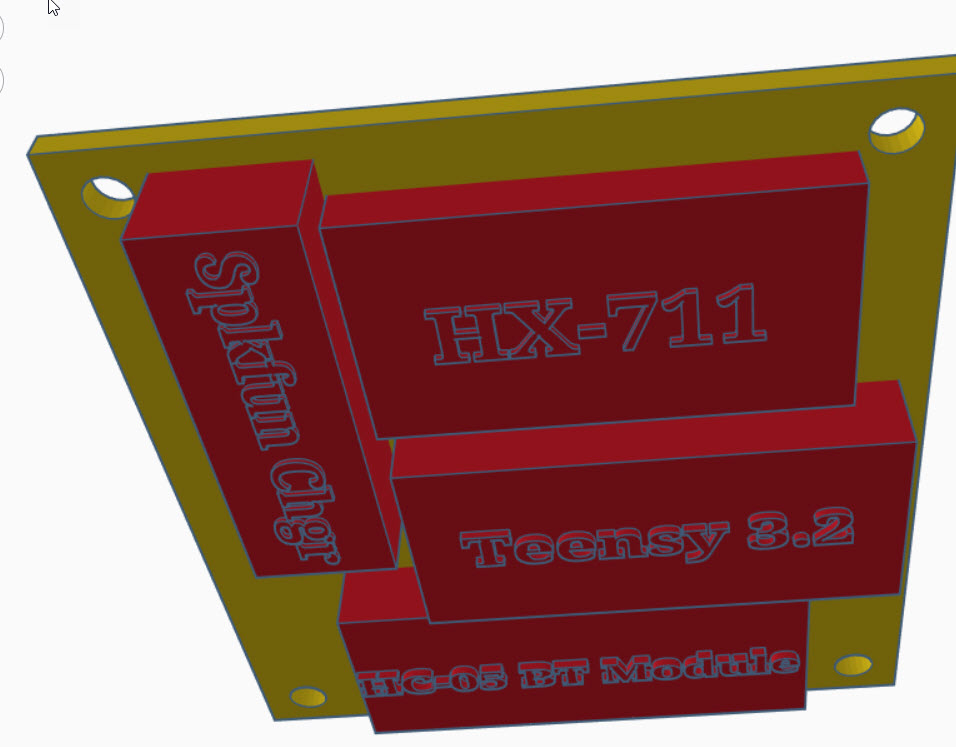

#include <SPI.h>

#include <Adafruit_GFX.h>

#include <Adafruit_PCD8544.h>

#pragma region LOW_POWER_SUPP

//12/03/18 added for low power mode

#include <Snooze.h>

// Load just the 'timer' wake-up driver

SnoozeTimer timer;

SnoozeUSBSerial usb;

SnoozeBlock config_teensy32(usb, timer);

const int SLEEP_TIME_MSEC = 5000;

//const float INACTIVE_SCALE_THRESHOLD_KG = 1.f;

const float INACTIVE_SCALE_THRESHOLD_KG = -10.f;

//const int MIN_INACTIVE_SCALE_COUNT = 100;

const int MIN_INACTIVE_SCALE_COUNT = 20;

int numInactiveScaleCounts = 0;

#pragma endregion Low Power Support

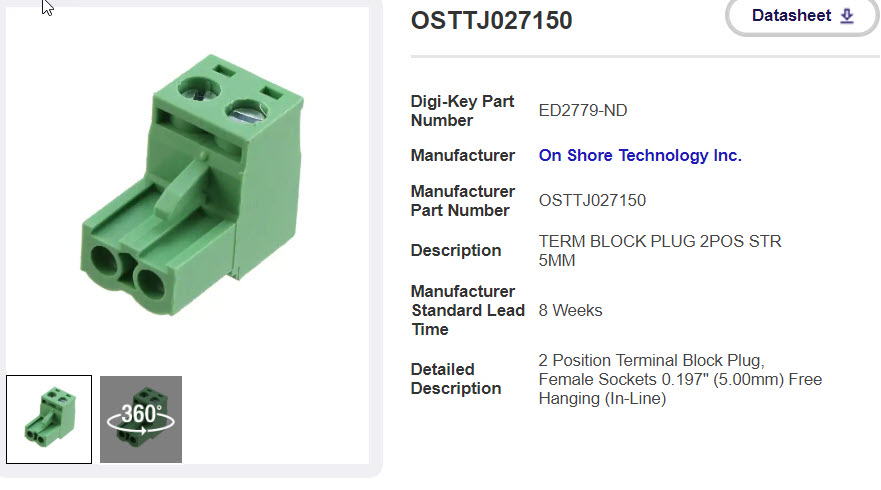

#pragma region LOAD_CELL

#include "HX711.h" //You must have this library in your arduino library folder

#include <EEPROM.h>

#include<EEPROMAnything.h> //so I can read the last calibration value from EEPROM

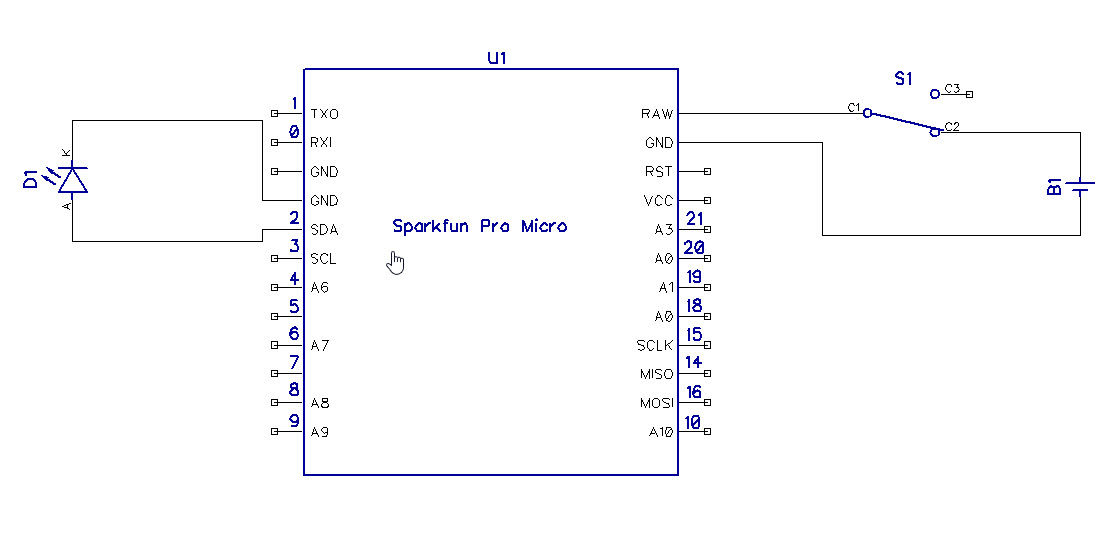

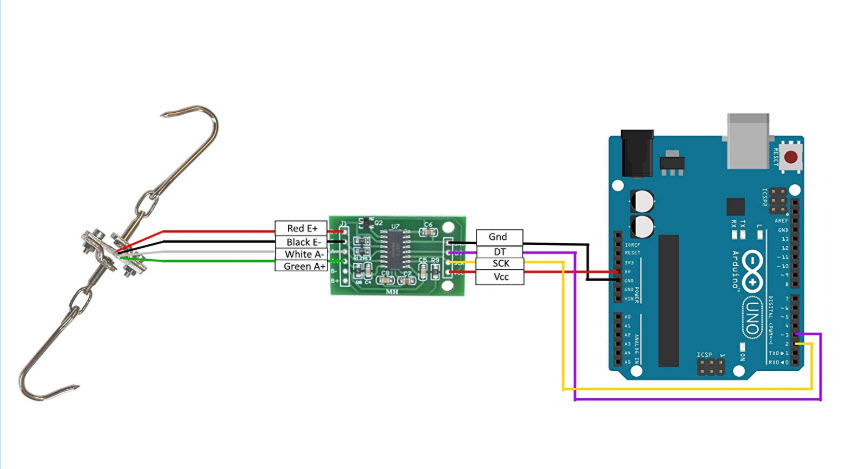

#define DOUT A1

#define CLK A0

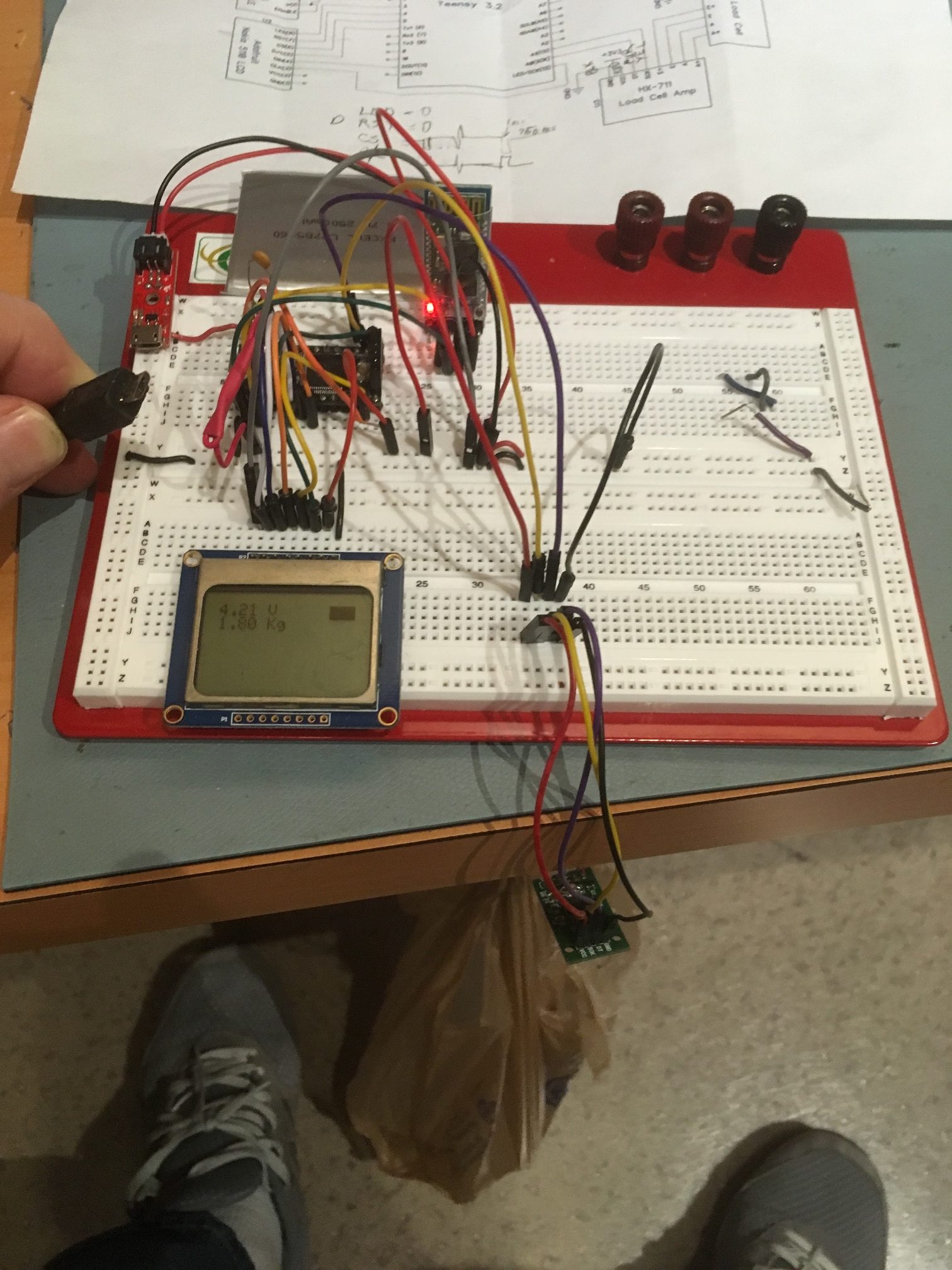

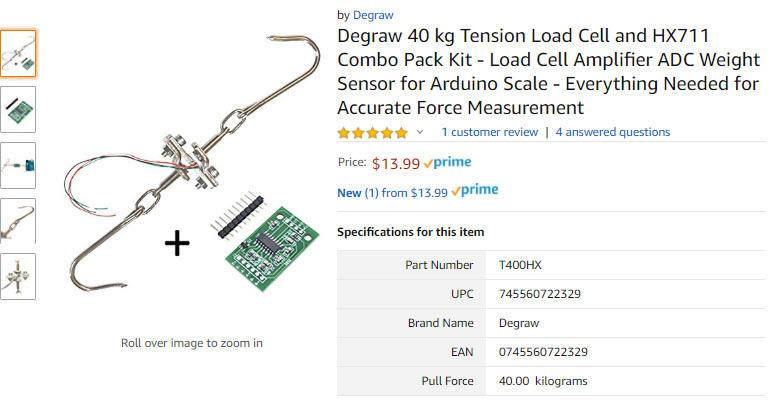

HX711 scale(DOUT, CLK);

//Change this calibration factor as per your load cell once it is found. You many need to vary it in thousands

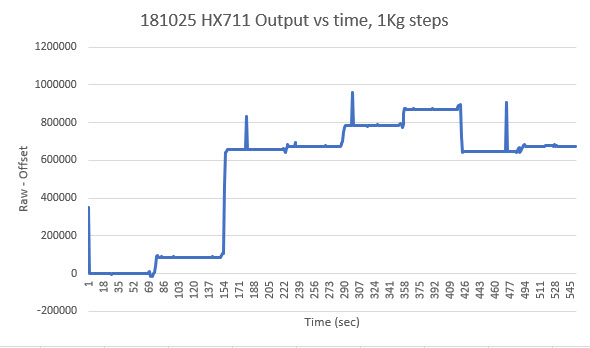

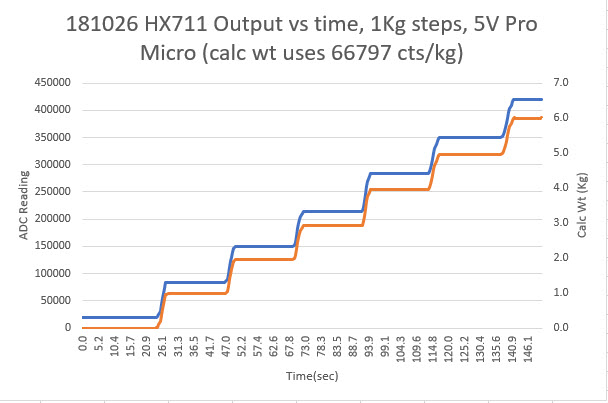

long calibration_factor = -96650; //-106600 worked for my 40Kg max scale setup

long tare_offset = 0;

const int LED_PIN = 13;

const int CAL_FACTOR_EEPROM_ADDR = 0;

const int TARE_OFFSET_EEPROM_ADDR = CAL_FACTOR_EEPROM_ADDR + sizeof(calibration_factor);

float scaleKg = 0;

float vBatt = 0;

#pragma endregion Load Cell Support

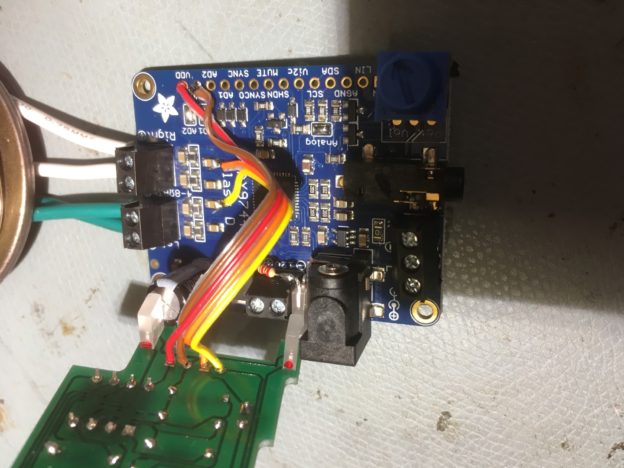

#pragma region LCD_DISPLAY

// Hardware SPI (faster, but must use certain hardware pins):

// Note with hardware SPI MISO and SS pins aren't used but will still be read

// and written to during SPI transfer. Be careful sharing these pins!

// SCK is LCD serial clock (SCLK) - this is pin 13 on Arduino Uno

// MOSI is LCD DIN - this is pin 11 on an Arduino Uno

// pin 6 - Data/Command select (D/C)

// pin 5 - LCD chip select (CS)

// pin 4 - LCD reset (RST)

const int LCD_DC_PIN = 6;

const int LCD_CS_PIN = 5;

const int LCD_RST_PIN = 4;

const int SPI_DOUT_PIN = 11;

const int SPI_SCK_PIN = A0;

//Adafruit_PCD8544 display = Adafruit_PCD8544(6, 5, 4);//11/25/18

Adafruit_PCD8544 display = Adafruit_PCD8544(LCD_DC_PIN, LCD_CS_PIN, LCD_RST_PIN);//12/16/18 chg to identifiers

#pragma endregion Noki LCD Display

#pragma region BATT_FUEL_GUAGE

const int BATT_SYMBOL_X = 68;

const int BATT_SYMBOL_Y = 1;

const int BATT_SYMBOL_H = 8;

const int BATT_SYMBOL_W = 16;

const int DEFAULT_CHAR_HEIGHT = 8;

const int DEFAULT_CHAR_WIDTH = 5;

const int DEFAULT_CHAR_SIZE = 2;

//added 12/03/18 for battV measurements

//12/06/18 changed to internal 1.2V reference and 30K:10K divider

const int DEAD_BATT_COUNTS = 642;

const int FULL_BATT_COUNTS = 887;

const float FULL_BATT_VOLTS = 4.2;

const float DEAD_BATT_VOLTS = 3.0;

const float VOLTS_PER_COUNT = (FULL_BATT_VOLTS - DEAD_BATT_VOLTS) / (FULL_BATT_COUNTS - DEAD_BATT_COUNTS);

#pragma endregion Battery Fuel Guage

void setup()

{

Serial.begin(115200);

delay(1000); //need this to get serial printout

Serial.println("Welcome to the Teensy Low Power Digital Scale Program");

Serial1.begin(9600);

Serial1.println("Welcome via Bluetooth!");

/********************************************************

Set Low Power Timer wake up in milliseconds.

********************************************************/

timer.setTimer(SLEEP_TIME_MSEC);// milliseconds

//12/04/18 added code to set analog reference to internal 1.2V source

analogReference(INTERNAL1V1);

//initialize load cell and retrieve cal/tar values from EEPROM

EEPROM_readAnything(CAL_FACTOR_EEPROM_ADDR, calibration_factor); //read current cal scale from EEPROM

Serial.printf("The current stored scale calibration factor is %li\n", calibration_factor);

scale.set_scale(calibration_factor);

EEPROM_readAnything(TARE_OFFSET_EEPROM_ADDR, tare_offset); //read current tare offset from EEPROM

Serial.printf("The current stored tare offset factor is %li\n", tare_offset);

scale.set_offset(tare_offset);

//initialize LCD display

display.begin();

display.setContrast(60); //pretty dark

display.setTextSize(1);

display.setTextColor(BLACK);

display.setCursor(0, 0);

display.display(); //first time - shows the Adafruit logo

delay(1000); //show Adafruit logo for 1 sec

display.clearDisplay(); // clears the screen and buffer

display.display(); //first time - shows the Adafruit logo

////initial battery and scale reading

//vBatt = UpdateBatteryDisplay();

//scaleKg = UpdateScaleDisplay();

//display.display();

}

void loop()

{

//12/06/18 now using 30K/10K voltage divider on A7 and 1.2V ref.

display.clearDisplay(); //clear memory bitmap

display.setCursor(0, 0);

vBatt = UpdateBatteryDisplay();

//scaleKg = UpdateScaleDisplay();

scaleKg = scale.get_units(3);

Serial1.printf("%5.3f\n\r", scaleKg); //to BT module

Serial.printf("%5.3f\n", scaleKg); //to serial console

display.print(scaleKg); display.println(" Kg");//to LCD display

display.display();

//if the scale has been quiet for a while, go to sleep

if (scaleKg <= INACTIVE_SCALE_THRESHOLD_KG)

{

numInactiveScaleCounts++;

if (numInactiveScaleCounts >= MIN_INACTIVE_SCALE_COUNT)

{

numInactiveScaleCounts = MIN_INACTIVE_SCALE_COUNT;

}

//numInactiveScaleCounts = (numInactiveScaleCounts >= MIN_INACTIVE_SCALE_COUNT) ?

// MIN_INACTIVE_SCALE_COUNT : numInactiveScaleCounts++;

//display.display();

}

else

{

numInactiveScaleCounts = 0; //one active measurment wakes everything up

//vBatt = UpdateBatteryDisplay();

//scaleKg = UpdateScaleDisplay();

//display.display();

}

if (numInactiveScaleCounts >= MIN_INACTIVE_SCALE_COUNT)

{

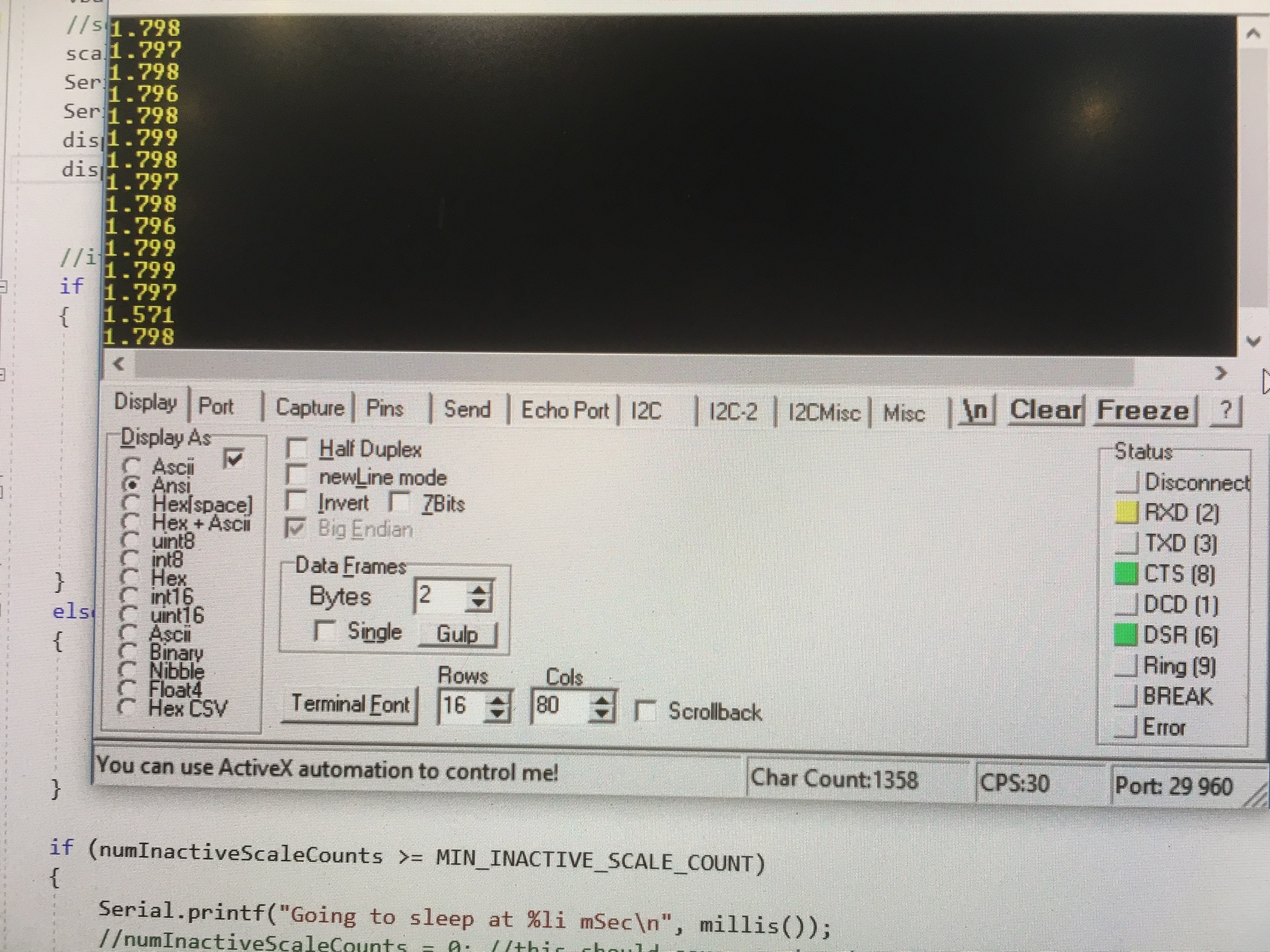

Serial.printf("Going to sleep at %li mSec\n", millis());

//numInactiveScaleCounts = 0; //this should cause system to stay awake for a second or so

display.clearDisplay();

display.display();

Snooze.sleep(config_teensy32); //sleep

}

delay(100);

}

float UpdateScaleDisplay()

{

float kG = scale.get_units(3);

//float kG = (float)random(0,40);

display.print(kG); display.println(" Kg");

return kG;

}

float UpdateBatteryDisplay()

{

int batt_counts = analogRead(A9);

float batt_volts = DEAD_BATT_VOLTS + (batt_counts - DEAD_BATT_COUNTS) * VOLTS_PER_COUNT;

display.print(batt_volts); display.println(" V");

UpdateBatterySymbol(batt_volts);

return batt_volts;

}

void UpdateBatterySymbol(float vbatt)

{

//Purpose: Update the battery symbol to show current charge state

//Inputs:

// vbatt = current battery voltage

// FULL_BATT_VOLTS = fully charged battery voltage

// DEAD_BATT_VOLTS = fully discharged battery voltage

// BATT_SYMBOL_X/Y/H/W = battery symbol loc/dims

//Outputs: Updated battery symbol

//Plan:

// Step1: draw open rect for battery symbol outline

// Step2: draw filled rect indicating charge state

// Step3: If vbatt <= DEAD_BATT_VOLTS, draw 'X' over symbol

//Step1: draw open rect for battery symbol outline

display.drawRect(BATT_SYMBOL_X, BATT_SYMBOL_Y, BATT_SYMBOL_W, BATT_SYMBOL_H, 1);

//Step2: draw filled rect indicating charge state

float Vrange = FULL_BATT_VOLTS - DEAD_BATT_VOLTS;

int fillWidth = (int)(BATT_SYMBOL_W * ((vbatt - DEAD_BATT_VOLTS) / Vrange) + 0.5f);

//Serial.printf("vbat, fillW = %4.2f,%d\n", vbatt, fillWidth);

display.fillRect(BATT_SYMBOL_X, BATT_SYMBOL_Y, fillWidth, BATT_SYMBOL_H, 1);

//Step3: If vbatt <= DEAD_BATT_VOLTS, draw 'X' over symbol

if (vbatt <= DEAD_BATT_VOLTS)

{

//try drawing lines from corner to corner

int ulX = BATT_SYMBOL_X;

int ulY = BATT_SYMBOL_Y;

int urX = BATT_SYMBOL_X + BATT_SYMBOL_W;

int urY = ulY;

int lrX = urX;

int lrY = urY + BATT_SYMBOL_H;

int llX = ulX;

int llY = lrY;

display.drawLine(ulX, ulY, lrX, lrY, 1);

display.drawLine(llX, llY, urX, urY, 1);

}

}